196 AC servo systems

Motor coil

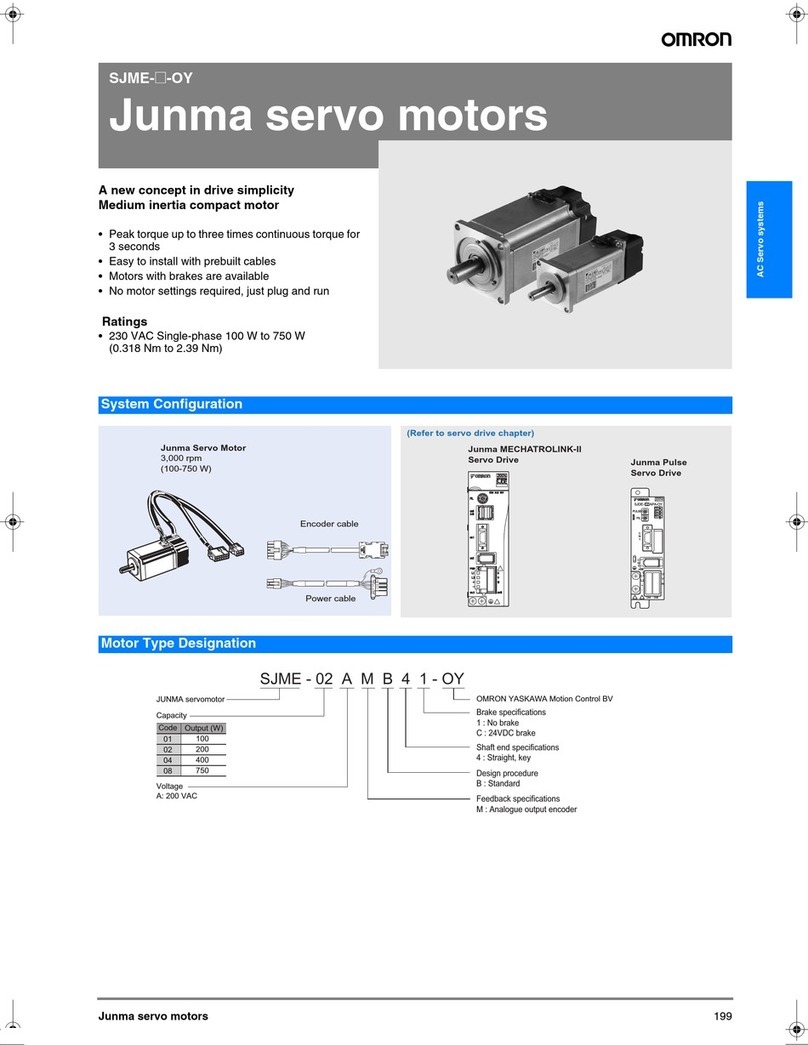

Servo Motor / Servo Drive Combination

Sigma series linear servo motor Serial converter Servo drive

JZDP-@008-[code] Sigma-II series XtraDrive

Type Voltage Rated

force Peak force Model code for

Rev A, B code for

Rev C 230 V

(1-phase) 400 V

(3-phase) 230 V

(1-phase) 400 V

(3-phase)

SGLGW coreless

standard-force

magnetic ways

230 V 12.5 N 40 N 30A050 [B / C] 158 250 SGDH-A5AE-OY - XD-P5-MN01 -

25 N 80 N 30A080 [B / C] 156 251 SGDH-01AE-OY - XD-01-MN01 -

47 N 140 N 40A140 [B / C] 001 252 SGDH-01AE-OY - XD-01-MN01 -

70 N 220 N 60A140 [B / C] 004 258 SGDH-02AE-OY - XD-02-MN01 -

93 N 280 N 40A253 [B / C] 002 253 SGDH-02AE-OY - XD-02-MN01 -

140 N 420 N 40A365 [B / C] 003 254 SGDH-04AE-OY - XD-04-MN01 -

140 N 440 N 60A253 [B / C] 005 259 SGDH-04AE-OY - XD-04-MN01 -

210 N 660 N 60A365 [B / C] 006 260 SGDH-08AE-S-OY - XD-08-MN -

325 N 1300 N 90A200 [A / C] 101 264 SGDH-15AE-S-OY - XD-15-MN -

SGLGW coreless

high-force

magnetic ways

230 V 57 N 230 N 40A140 [B / C] 059 255 SGDH-02AE-OY - XD-02-MN01 -

114 N 460N 40A253 [B / C] 060 256 SGDH-04AE-OY - XD-04-MN01 -

171 N 690 N 40A365 [B / C] 061 257 SGDH-08AE-S-OY - XD-08-MN -

85 N 360N 60A140 [B / C] 062 261 SGDH-02AE-OY - XD-02-MN01 -

170 N 720 N 60A253 [B / C] 063 262 SGDH-08AE-S-OY - XD-08-MN -

255 N 1080 N 60A365 [B / C] 047 263 SGDH-15AE-S-OY - XD-15-MN -

Type Voltage Rated

force Peak force Model code 230 V

(1-phase) 400 V

(3-phase) 230 V

(1-phase) 400 V

(3-phase)

SGLFW

linear motors 230 V 25 N 86 N 20A090A 017 SGDH-02AE-OY - XD-02-MN01

40 N 125 N 20A120A 018 SGDH-02AE-OY - XD-02-MN01

80 N 220 N 35A120A 019 SGDH-02AE-OY - XD-02-MN01

160 N 440 N 35A230A 020 SGDH-08AE-S-OY - XD-08-MN01

280 N 600 N 50A200B 181 SGDH-08AE-S-OY - XD-08-MN

560 N 1200 N 50A380B 182 SGDH-15AE-S-OY - XD-15-MN

560 N 1200 N 1ZA200B 183 SGDH-15AE-S-OY XD-15-MN

400 V 80 N 220 N 35D120A 211 - SGDH-05DE-OY - XD-05-TN

160 N 440 N 35D230A 212 - SGDH-05DE-OY - XD-05-TN

280 N 600 N 50D200B 189 - SGDH-10DE-OY - XD-10-TN

560 N 1200 N 50D380B 190 - SGDH-15DE-OY - XD-15-TN

560 N 1200 N 1ZD200B 191 - SGDH-15DE-OY - XD-15-TN

1120 N 2400 N 1ZD380B 192 - SGDH-30DE-OY - XD-30-TN

1500 N 3600 N 1ED380B 333 - SGDH-20DE-OY - XD-20-TN

2250 N 5400 N 1ED560B 334 - SGDH-30DE-OY - XD-30-TN

SGLTW

linear motors 400 V 300 N 600 N 35D170H 193 - SGDH-10DE-OY - XD-10-TN

600 N 1200 N 35D320H 194 - SGDH-20DE-OY - XD-20-TN

450 N 900 N 50D170H 195 - SGDH-10DE-OY - XD-10-TN

900 N 1800 N 50D320H 196 - SGDH-20DE-OY - XD-20-TN

670 N 2600 N 40D400B 197 - SGDH-30DE-OY - XD-30-TN

1000 N 4000 N 40D600B 198 - SGDH-50DE-OY - XD-50-TN

1300 N 5000 N 80D400B 199 - SGDH-50DE-OY - XD-50-TN

2000 N 7500 N 80D600B 200 - SGDH-75DE-OY - -

㧙

Linear Σseries

Linear servo motor

Voltage

Length of coil assembly

A㧦200 VAC

D㧦400 VAC

35 D 120 A P

Servo motor model

Code

G

F

T

Specifications

Coreless

F-type iron core

T-type iron core

Options

Code

P

H

Specifications

With hall sensor (standard)

Forced cooling

With hall sensor and forced cooling

C

W : Coil assembly

Magnet height

WFSGL

Design revision order

A,B,C

D

Cable connector for main circuit cable

Code

−

D

Specifications

MS connector or connector made

by Tyco Electronics AMP K.K.

Connector made by Interconnectron

Y203-EN2-02-Katalog.book Seite 196 Mittwoch, 24. Mai 2006 2:22 14