Pullman Holt MAGNETspray User manual

OWNER’S MANUAL

FOR THE

MAGNETspray

Pullman-Holt Corporation

Main Office: 10702 North 46th Street Tampa, FL. 33617

Phone: (813) 971-2223 · FAX: (813) 971-6090

Operation Guide

To Operate:

1

Prepare the tank mix.

2

Connect the twinline hose to the front panel.

3

Connect the twinline hose to the liquid and air leaders on the

handgun. If using the plastic bottle, connect the grey hose of the

plastic bottle hose assembly instead of the solution hose of the

twinline hose to the liquid leader.

4

Plug the power cord into an appropriate receptacle. Turn on the

air compressor.

5

Engage the trigger and spray.

To clean the sprayer after operation:

1

Clean the exterior of the sprayer.

2

Clean the tank and/or the plastic bottles

3

Disconnect the twinline hose from the handgun air line and liquid

line leaders.

4

Disassemble and clean the liquid filter. Be careful not to lose the

flow disk

5

Unthread the quick connect plug from the handgun liquid line

leader. Use a 7/16” wrench on the plug and an 11/16” wrench on

the 1/8” NPT body.

6

Connect the quick connect plug to the grey hose of the twinline

hose.

7

Fill the tank with 2 gallons of clean water.

8

Turn on the air compressor to flush the line with 1.75 gallons of

water. Turn off the air compressor.

9

Disconnect the quick connect plug from the twinline hose. Re-

thread it into the handgun liquid line leader.

10

Reassemble the liquid filter.

11

Turn on the air compressor and engage the trigger to flush the

handgun lines with the remaining water. Check the nozzles for a

good spray pattern while flushing. Allow air to flow for 30 seconds

after the water has been sprayed.

12

Apply silicone spray or similar lubricating oil to all quick connect

fittings.

13

Record application in the Spray Log.

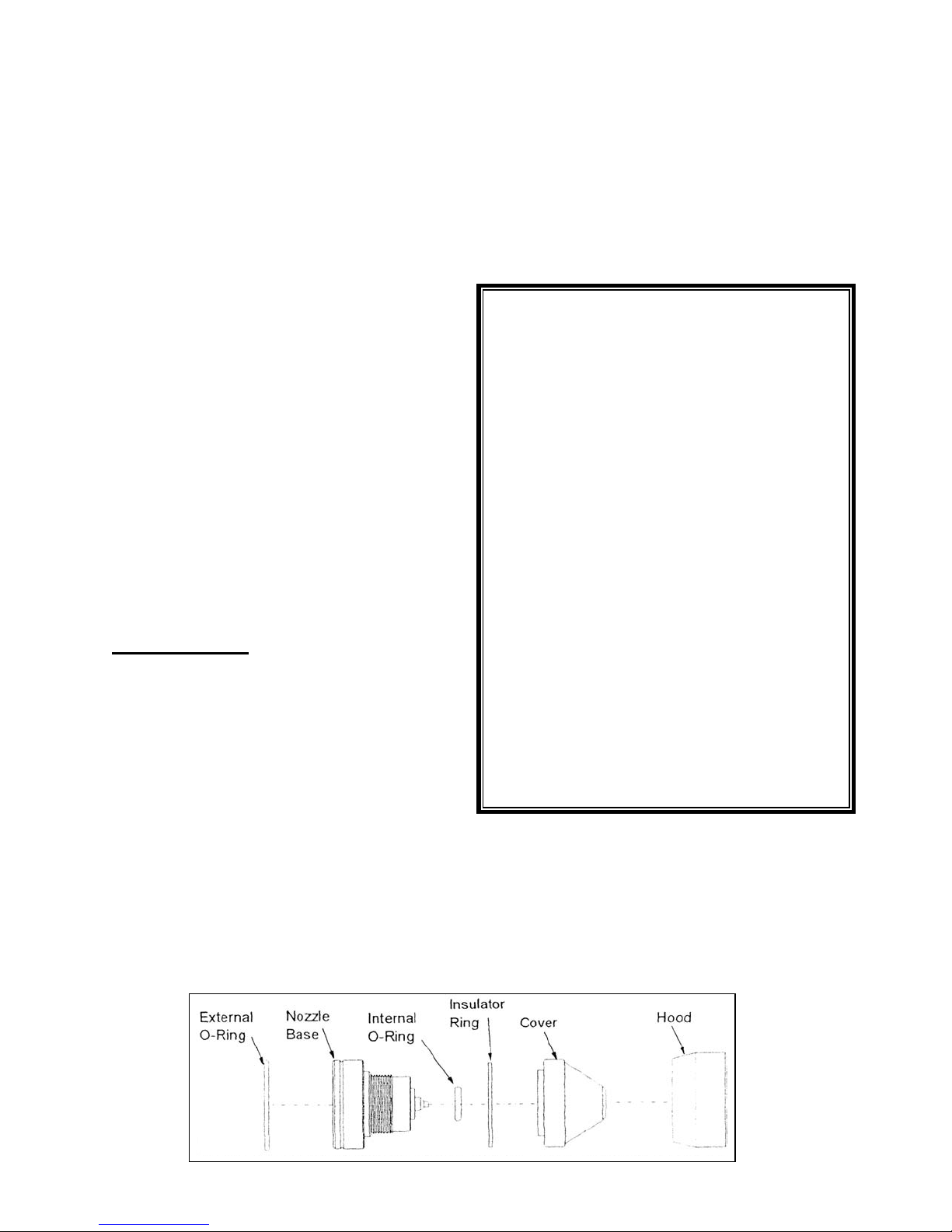

The Nozzle Assembly

The nozzle assembly is located at the end of

the handgun wand. It is composed of a

nozzle base, internal o-ring, Teflon ring,

cover, external o-ring, and a hood (see

Diagram 5). To access nozzle components,

just unscrew the nozzle cover by hand.

In order to optimize nozzle life and achieve

maximum spray efficiency, the nozzle must

be properly maintained. Always rinse the

handgun out with clean soapy water after

every spray, and establish maintenance

intervals to disassemble and clean the

nozzle. You may wish to purchase tank

cleaner, which cuts hard water scale and

chemical deposits from the electrode and

internal component of the gun. Your nozzle

maintenance schedule will vary depending on

the types of chemicals used and adherence

to pre and post spray checks, In general it is

sufficient to thoroughly clean nozzles every

50 hours. If heavy loads of wettable powers

are used, the cleaning schedule should be

sooner.

Pre-Spray Check

I. Inspect Nozzles

Check nozzle cover to make sure it is on

hand tight (do not over tighten or use a

wrench). Make sure the hood is seated firmly

to the nozzle base and against the external o-

ring.

II. Preparing the Tank Mix

If you will be spraying wettable powders it is a

good idea to use a compatibility agent with

the water and tank mix. Compatibility agents

are chemicals mixed with the water that make

mixing easier and keep heavy concentrations

uniformly in suspension.

Post-Spray Check

After each spray it is essential that hoses and

handgun be flushed with clean soapy water.

This will help prevent chemical build-up that

can clog lines and nozzles. Also, it is

recommended that the nozzle exterior (black

portion of nozzle) and nozzle hoods be

cleaned with soapy water at this time.

To clean the nozzle assembly:

1. Slide the hood over the nozzle cover.

2. Unscrew the cover from the nozzle base

and remove the Teflon ring. Note: There

is a small o-ring in the nozzle around the

base of the tip, take care that it doesn’t

fall off. If it does, clean it and press back

into place. Also, take care not to damage

the nozzle tip when the cover is removed.

3. Soak the ring, cover, and hood in a mild

detergent solution. Use a small brush

(soft or mild bristle) to clean the inside of

the cover and the hole through it. Also,

be sure to clean the hood. Rinse.

4. Scrub the nozzle base with the detergent

solution using a soft bristle brush. Be

sure to thoroughly clean the base cavity

and take care not to damage the nozzle

tip. Rinse and make sure the small o-ring

is in place.

5. Reassemble nozzle by placing the Teflon

ring on the base and screwing the cover

on hand tight. Next, slide the hood over

the nozzle and seat it securely against the

external o-ring.

Diagram 4: The Nozzle Assembly

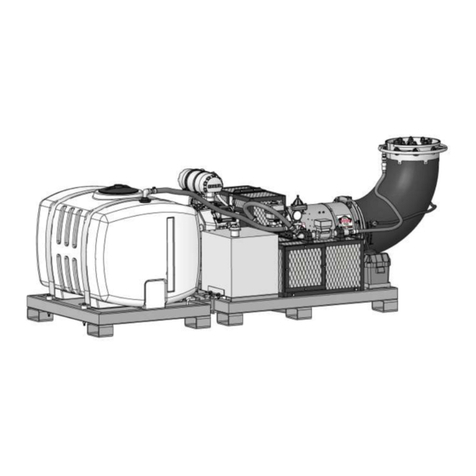

The Air & Liquid Delivery System

The Air Compressor

The air compressor produces compressed

air which atomizes and propels the liquid. It

plugs into a 110 volt electrical source. Use

the unit with an extension cord of no more

than 50 feet and rated for no less than 15

amp service. The On/Off switch is on the

side of the air compressor. The compressor

has an adjustable relief valve on the back.

It should be set between 70 and 100 psi.

The Front Panel Air Connection

The second tee routes the air to the top ¼”

female ball swivel (FBS) fitting on the front

panel of the sprayer. The ¼” end of the air

hose of the twinline hose connects to this

fitting. Use an 11/16” wrench on the FBS

and 9/16” wrench on the twinline hose

fitting. The other end of the twinline hose

connects to the air leader of the handgun.

The Tank Pressure Regulator

The second tee also routes air to the tank

pressure regulator. It corresponds with the

pressure gauge on the left side of the front

panel. The regulator is operated by pulling

out the dial and turning it clockwise to

increase pressure or counter-clockwise to

decrease pressure. It should be set

between 12 and 15 psi. Once the desired

pressure is achieved, push in the dial to lock

it in place.

Note: For best results, set the pressure

from a lower pressure to a higher pressure.

If the pressure is set too high, adjust the

regulator below the desired pressure then

adjust it up to the desired pressure.

Two lines run from the tank pressure

regulator. One line runs to the tank

pressure gauge on the front panel. The

other runs to the inlet quick connect on the

tank.

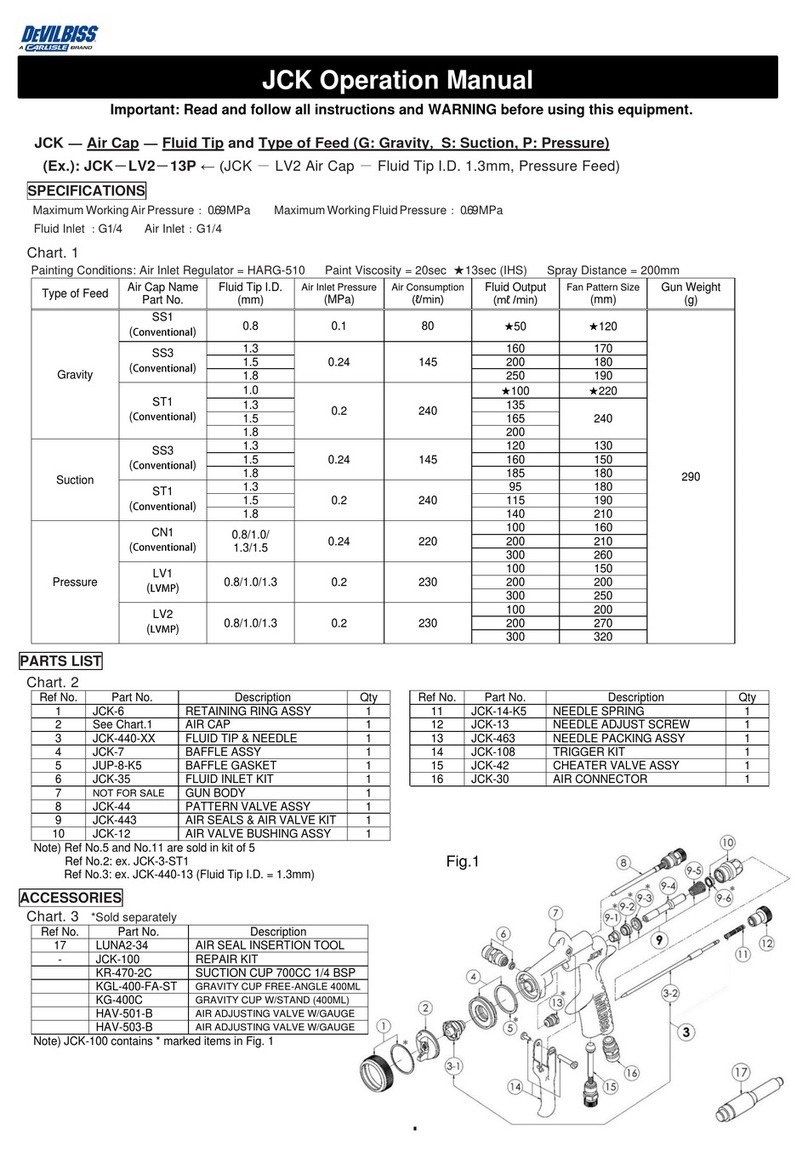

Figure 2. The Air and Liquid Delivery Systems

To disconnect the quick connects:

1. Slide the sleeve on the quick

connect socket up.

2. While holding the sleeve up, pull the

socket off the quick connect plug.

To connect the quick connects:

1. Slide the sleeve of the quick connect

socket up.

2. While holding the sleeve up, push

the socket onto the quick connect

plug.

3. Release the sleeve.

4. Pull on the socket body to ensure

that it is properly seated and cannot

be pulled off the plug when the

sleeve is down.

To open the tank:

1. Push up the lever on the tank lid so

it is vertical. This depressurizes the

tank.

2. Pull the handle of the tank lid up.

3. Holding on to the handle, rotate the

tank lid 90° clockwise.

4. Pull out the tank lid. Notice the

direction of the tank lid in

relationship to the tank opening.

To close the tank:

1. Slide the lid into the tank opening,

using the same direction as when it

was removed.

2. Rotate the lid 90° counterclockwise.

3. While pulling the lid up to seal it

against the tank opening, push

down on the lid handle until it is

parallel with the tank lid.

4. Push the pressure valve lever down

so it is horizontal.

The Quick Connects

There are four sets of quick connects (plug

and socket) on the sprayer: tank inlet, tank

outlet, handgun liquid inlet, and handgun air

inlet.

The Tank

The tank should be thoroughly cleaned

immediately after each use by triple-rinsing

the tank; a commercially available tank

cleaner may be used and is recommended

when the unit is used to spray wettable

powders on a regular basis.

Note: Do not operate the sprayer when the

tank lid is not securely closed. Tank

agitation is powerful and liquid may splash

out if the lid is not closed.

To clean the air filter:

1. Unthread the casing from the cap

using a ¾” wrench on both parts.

Be careful not to lose the spring or

the air filter inside of the casing.

2. Check inside each part for debris.

Clean any dirt out with compressed

air or warm, soapy water.

3. Reassemble the air filter, making

sure to put it together as in Diagram

2.

To engage/disengage the trigger:

1. Pull the trigger up towards the body

of the handgun to start spraying.

2. To keep spraying, either keep

holding the trigger or lock it in place

by pulling up the lock and hooking

the trigger.

3. To stop spraying when the trigger is

not locked, let go of the trigger.

To clean the trigger:

1. Unthread the brass bolt on the top of

the handgun with a 5/8” socket

wrench. Be careful not to lose the

spring, plunger, copper washer, and

small brass bushing inside the

trigger. Note how they fit inside so

they may be replaced properly.

2. Check inside the trigger for

blockage. Clean out any debris with

compressed air or warm, soapy

water.

3. Replace the spring and plunger;

rethread the brass bolt into the top

of the handgun until tight.

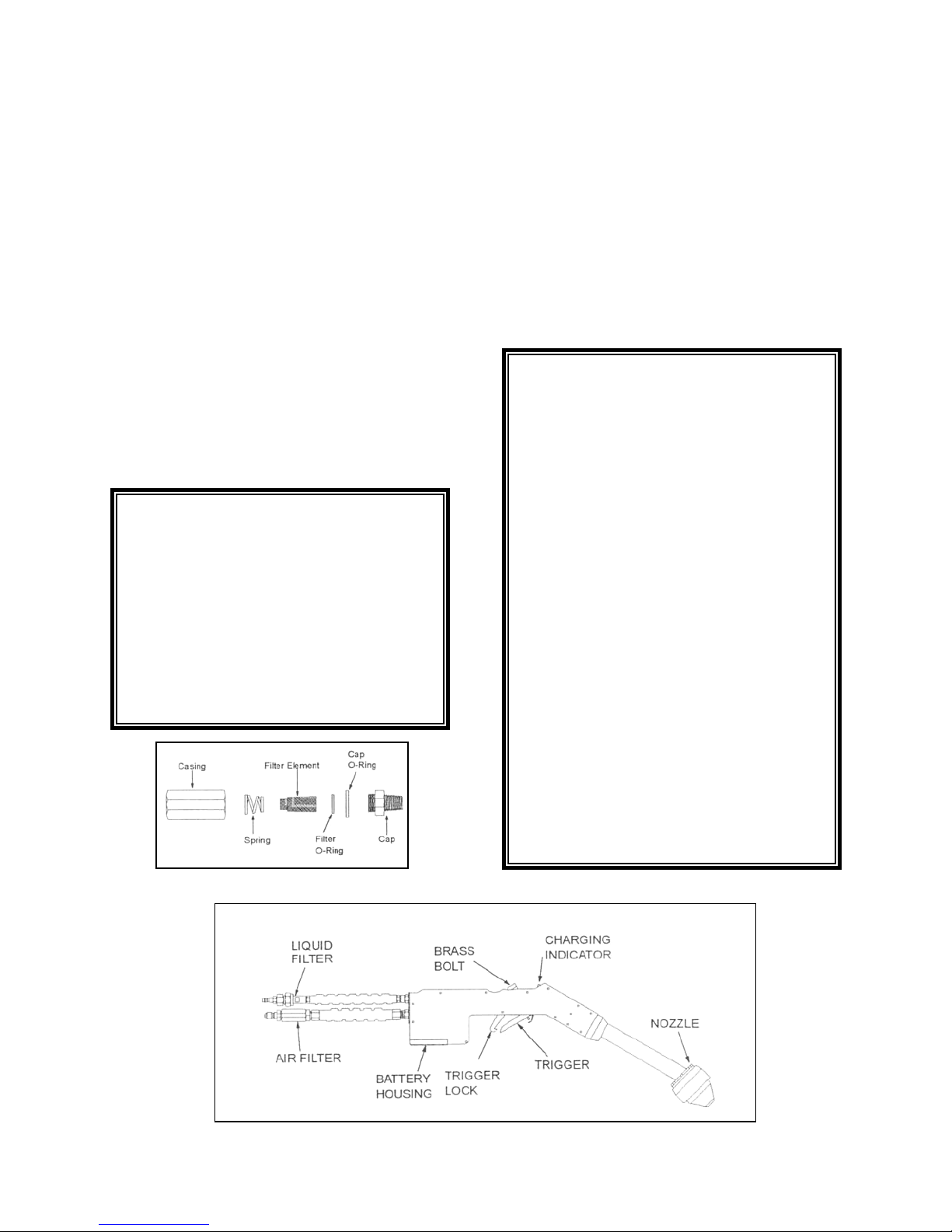

The Handgun

The handgun is held by the operator during

spraying. Activation of the trigger causes

liquid to spray. The handgun has the

following user-serviceable parts: the air

filter, the liquid filter assembly, the nozzle

assembly, and the batteries. Except for the

batteries, which are accessed by removing

the battery cover, nothing inside the

handgun shell is user-serviceable. Do not

open the handgun shell; doing so will void

the warranty on the handgun.

The Air Filter

The air filter is located outside the base of

the handgun in the air hose. It filters dirt out

of the air lines. There is an extra air filter in

the bag which is stapled to this manual in

case the original is lost or damaged.

The Trigger

The trigger turns the spray on and off. It

can be continuously held for operation or it

can be locked in place. When it is on, the

charging indicator on the top of the handgun

shell glows red to indicate that the nozzles

are charging.

Diagram 1. The Handgun

Diagram 2. The Air Filter

To change the batteries:

1. Unscrew the 2 6-32 x ½” phillips

head machine screws which hold

the battery cover in place.

2. While holding the leads in one hand,

gently disconnect the batteries from

the leads. Be careful not to tear the

leads off the wires or the tear the

lead wires out of the power supply.

3. Connect 2 fresh 9 volt batteries to

the leads.

4. Replace the battery cover. Screw

the 2 6-32 x ½” Phillips head

machine screws back in to secure

the battery cover.

The Batteries

The nozzle charging operates on two 9 volt

rechargeable batteries which are located in

the base of the handgun. In average

conditions, the batteries will last 5-10 hours

of operation on a charge. They should be

recharged when the charging indicator on

top of the handgun shell doesn’t glow when

the trigger is engaged during operation.

After a while the batteries will wear out and

need to be changed. Replace with Nickel-

Hydride rechargeable batteries.

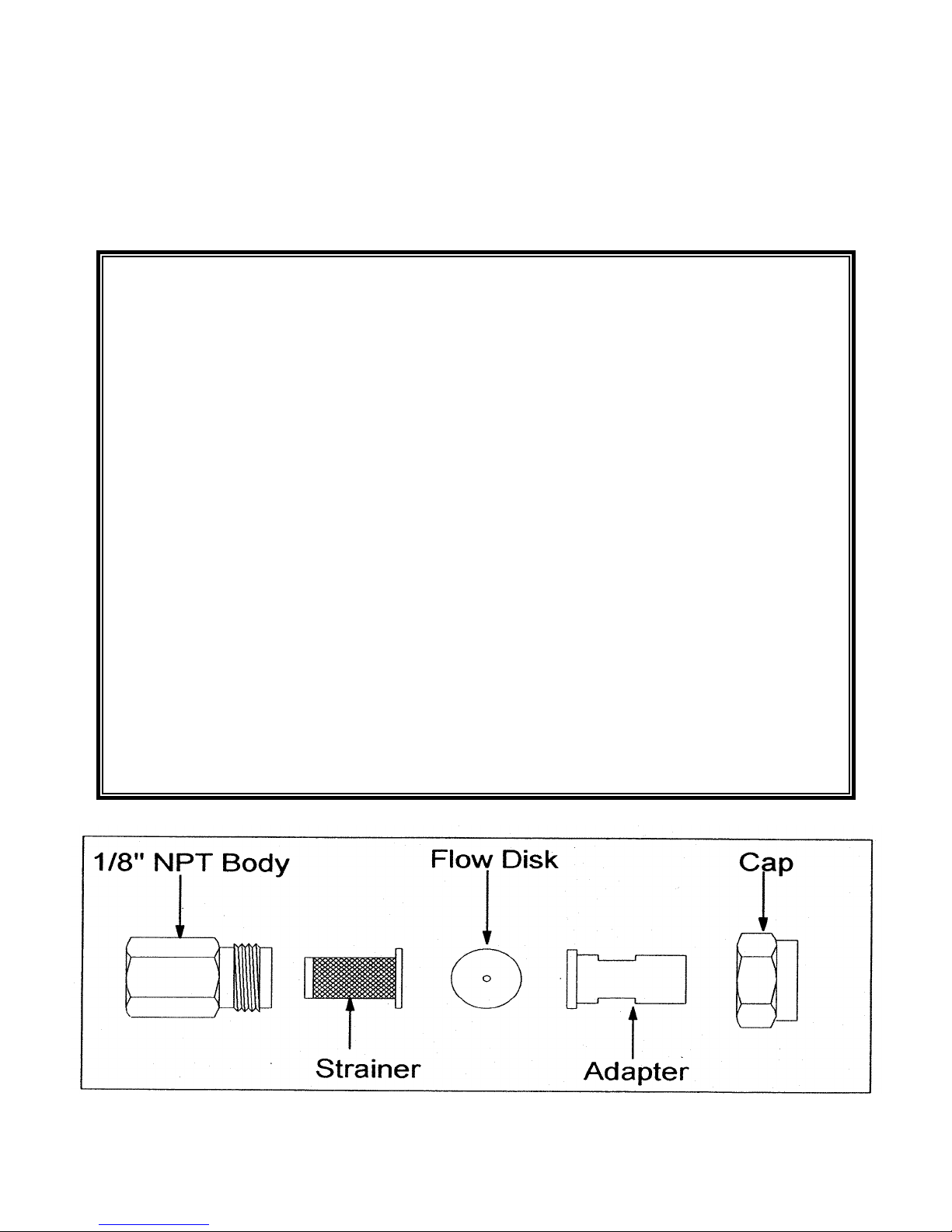

The Liquid Filter Assembly

The liquid filter assemby is located

outside the base of the handgun. It

is composed of these parts: a 1/8”

NPT body (item 10), a strainer (item

11), and a cap (item 12). The

strainer is the active filtering element

in the volume of liquid that flows

through the line. There is an extra

flow disk and an extra strainer in the

bag which is stapled to this manual

in case the originals are lost or

damaged.

To disassemble, clean and reassemble the liquid filter assembly:

1. Using a 13/16” wrench on the cap and and 11/16” wrench on the 1/8” NPT body,

unthread them.

Note: When you disassemble the liquid filter assembly, notice how the parts fit

together in order to reassemble them properly. Be careful not to lose any parts,

particularly the flow disk which is inside the cap. The sprayer will not function

correctly without the flow disk.

2. Remove the strainer from the 1/8” NPT body.

3. If the 1/8” NPT body contains residue, clean it with compressed air or clean

water.

4. Clean the strainer with compressed air or clean water. If residue still remains in

the 50 mesh screen, disassemble the Strainer. Unscrew the top brass part from

the bottom brass part. The 50 mesh screen slides off the brass body and can be

cleaned with compressed air or clean water. If residue still remains, soak the 50

mesh strainer in water. If necessary, scrub it with a soft toothbrush to remove

stubborn residue. Replace the 50 mesh screen and screw the top brass part

back on the lower brass part.

5. If the flow disk is still in the cap, remove it. Check the aperture of the flow disk for

blockage. If there is any, clean it with compressed air or clean water. Replace

the flow disk so that the numbers on the disk face the strainer.

6. Replace the strainer in the 1/8” NPT body.

7. Rethread the 1/8” NPT body and the cap.

Diagram 3: The Liquid Filter Assembly

TROUBLE-SHOOTING GUIDE

Problem: Air pressure of spray appears low:

1. Clean the liquid filter assembly. See “The Liquid Filter Assembly”.

2. Make sure that the liquid filter assembly is installed correctly. See Diagram 3 on p. 12.

3. Make sure that the air filter is installed correctly. See Diagram 2 on p. 11.

4. Clean the air filter. See “The Air Filter”.

5. Clean the trigger. See “To Clean the Trigger”.

Problem: No spray comes out of the nozzle or spray is erratic:

1. Make sure that the air pressure regulator is set between 12-15 psi.

2. Make sure that water temperature is at least 50° (10°C).

3. Make sure that all liquid fittings and air fittings are tight.

4. Clean the liquid filter assembly. See “The Liquid Filter Assembly”

5. Clean the nozzle assembly. See “The Nozzle Assembly”.

6. Clean the trigger. See “To Clean the Trigger:.

Problem: Charging indicator blinks or goes out during operation:

1. Change the batteries. See “The Batteries”.

2. Clean the Nozzle. See “The Nozzle Assembly”.

Problem: Air compressor will not start:

1. Make sure that the electrical cord is plugged in an appropriate receptacle.

2. Make sure that the switch on the side of the air compressor is on.

TANK PLUMBING ASSEMBLY

XT SERVICE PARTS

MAIN ASSEMBLY

Unlike conventional sprayers, your sprayer

uses a different method for chemical

application. Therefore, new techniques must

be used to spray and new formulas

developed to properly prepare tank mix. This

section will discuss proper spray techniques

and how to prepare a tank mix.

Note: When using unfamiliar equipment or

chemicals, always test on a small area before

treating the entire crop. Do not use a

chemical with the sprayer if the label

prohibits use in low-volume sprayers.

at full rate, you can start reducing the amount

of chemical used for each spray. Keeping the

amount of water in the tank constant, cut the

amount of chemical mixed in by 15-25% for

each spray until a desirable kill is no longer

achieved. If you are planning to cut rates

then it is very important to scout your crop to

determine spray efficiency.

HANDGUN SERVICE

PARTS

Other manuals for MAGNETspray

1

Table of contents

Other Pullman Holt Paint Sprayer manuals