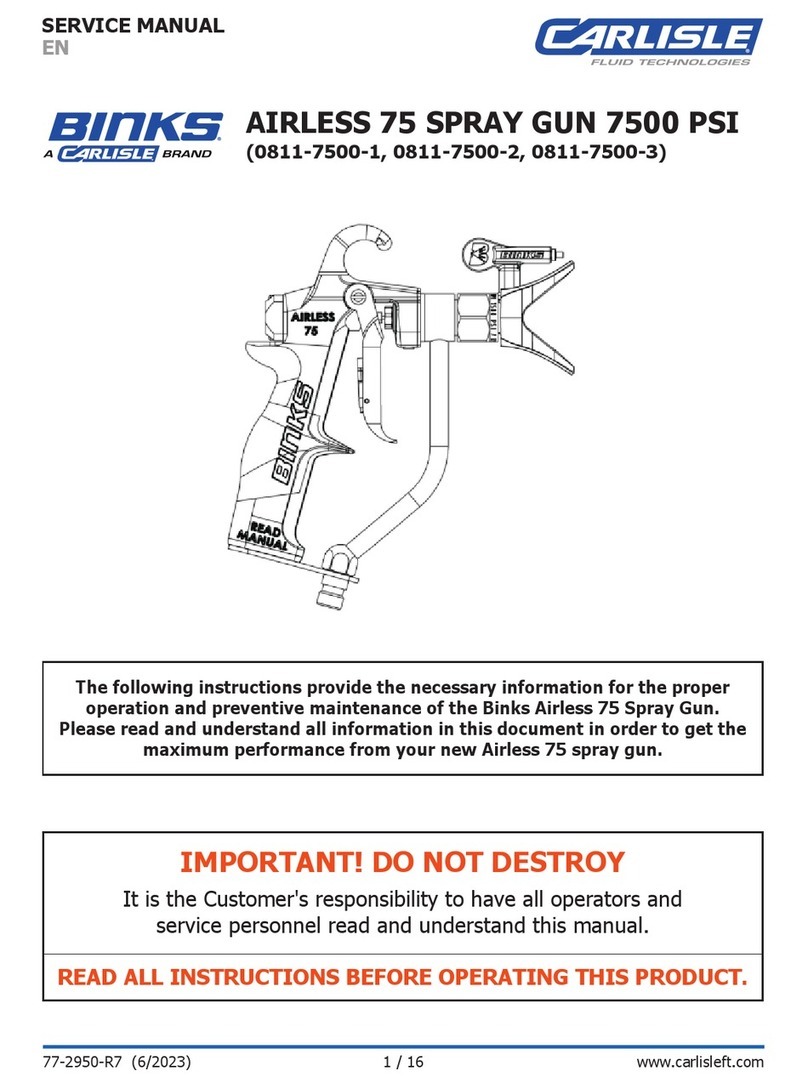

PREVENTIVE MAINTENANCE

1.

Dailylubricationandcleaningarenecessarytomaintainthebestconditionofthegun.

2.

Toclean the gun body,wipe exterior with solvent or cleaning solution dampened cloth.

Do not immerse the gun in a solvent or cleaning solution as it may damage the gun or

cause painting problems.

3. After using the gun, remove the paint and then pass an appropriate solvent or cleaning

solution through the paint path to wash away any remaining paint.

4. Do not leave any solvent or cleaning solution in the paint path or paint cup. It may cause

corrosion or damage.

5.

The AIR CAP (2) can be immersed in solvent and brushed down for cleaning. If orifices

are clogged, use a toothpick to remove obstruction. Never use a steel wire or hard

instrument. Thiswilldamageaircapandresultinadistortedspraypattern.

6.

The following portions should be lubricated regularly (

➡

in Fig.2); Sliding points of

TRIGGER KIT(14), PATTERN VALVE ASSY (8), CHEATAR VALVE ASSY (15),

NEEDLE ADJUST SCREW (12), AIR VALVE (9-4), and NEEDLE (3-2).

◆

For lubrication, SSL-10 Gun Lube* is recommended. (*Sold separately, contains NO

silicones or petroleum distillates.)

◆

Do not lubricate to any portion where not instructed.

7.

When installing AIR CAP (2), make sure no foreign materials adhered on RETAINING

RING ASSY (1)andthreadofbodyandthenoilonedropofGunLubeSSL-10.(

⇒

inFig.2)

8.

Apply non-silicone grease lightly on NEEDLE SPRING (11) and AIR VALVE SPRING

(9-5). Do not apply too much grease as itmayclogtheairpassage.

REPLACEMENT OF PARTS

Before replacing gun parts, remove materials from the gun for cleaning. Then release the air pressure of the gun and remove all hoses

and paint containers.Perform the replacement work in a clean place and fix the gun properly. Usetheappropriatetoolsindicatedfor

replacementofparts.

After replacing the parts, check the gun that the replaced parts are functioning properly.

FLUID TIP & NEEDLE (3)

1.

LoosencompletelyPATTERNVALVEASSY(8)knobbyturningtheknobcounterclockwise.

2.

RemoveNEEDLE ADJUST SCREW (12)and NEEDLE SPRING (11)and then withdraw NEEDLE (3-2).

3.

RemoveRETAININGRING ASSY(1)andAIRCAP (2).

4.

RemoveFLUID TIP (3-1)by using 19mm wrench.

5.

Clean the seal surface on the GUN BODY side and tighten a new FLUID TIP with a torque wrench (recommended tightening torque:

8N-m).

6.

Insert a new NEEDLE and NEEDLE SPRING and install the NEEDLE ADJUST SCREW.

FLUID INLET (6), AIR CONNECTOR (16)

FLUID INLET KIT

(6) and AIR CONNECTOR (16) are fixed together by sealing material. Do not remove these parts unless necessary, as it

may cause damage.

PATTERN VALVE ASSY (8), CHEATER VALVE ASSY (15)

Disassembling and reassembling PATTERN VALVE ASSY (8) and CHEATER VALVE ASSY (15) by using 13mm wrench. When disassembling

and

reassembling

, turn the knobs

fully

counterclockwise

.

AIR SEALS & AIR VALVE KIT(9)

1.

Remove NEEDLE ADJUST SCREW (12) and NEEDLE SPRING (11) andthen withdraw NEEDLE (3-2).

2. Remove AIR VALVE BUSHING (10) by using 14mm wrench.

3.

WithdrawVALVESPRING (9-5), AIR VALVE(9-4).

4.

Withdraw VALVE SEAT (9-3). Make sure not to damage the seal surface on the GUN BODY side.

5.

Remove LOCK SCREW (9-2) by using 7mm hex wrench.

Make sure not to damage the seal surface on the GUN BODY side.

6.

Push the AIR SEAL(9-1) toward the back of the GUN BODY toremoveit.

7.

Remove the AIR SEAL (9-6) inside the AIR VALVE BUSHING. Make sure not to damage the seal surface on the AIR VALVE BUSHINGside.

◆

DonotreusetheremovedAIRSEALS & AIR VALVE KIT.

8.

Install the new AIR SEALS & AIR VALVE KIT carefully in the reverse procedure of removal.

◆

The optional part; AIR SEAL INSERTION TOOL (17) is recommended for inserting the AIR SEALS (9-1, 3, 6).

9.

Install the NEEDLE, NEEDLE SPRING and NEEDLE ADJUST SCREW.

NEEDLE PACKING ASSY (13)

1.

Remove NEEDLE ADJUST SCREW (12) and NEEDLE SPRING (11) andthen pull out NEEDLE (3-2).

2.

Remove NEEDLE PACKING ASSY (13) by using10mm wrench.

3. Install a new NEEDLE PACKING ASSY. Use a 10mm wrench to tighten it until it stops lightly first, and then tighten it about 1/16 turn.

4.

Install the NEEDLE, NEEDLE SPRING and NEEDLE ADJUST SCREW.