Introduction............................................................................................................................................................................3

Safety Rules ...........................................................................................................................................................................4

Safety Symbols ...........................................................................................................................................................4

Safety Instructions ......................................................................................................................................................4

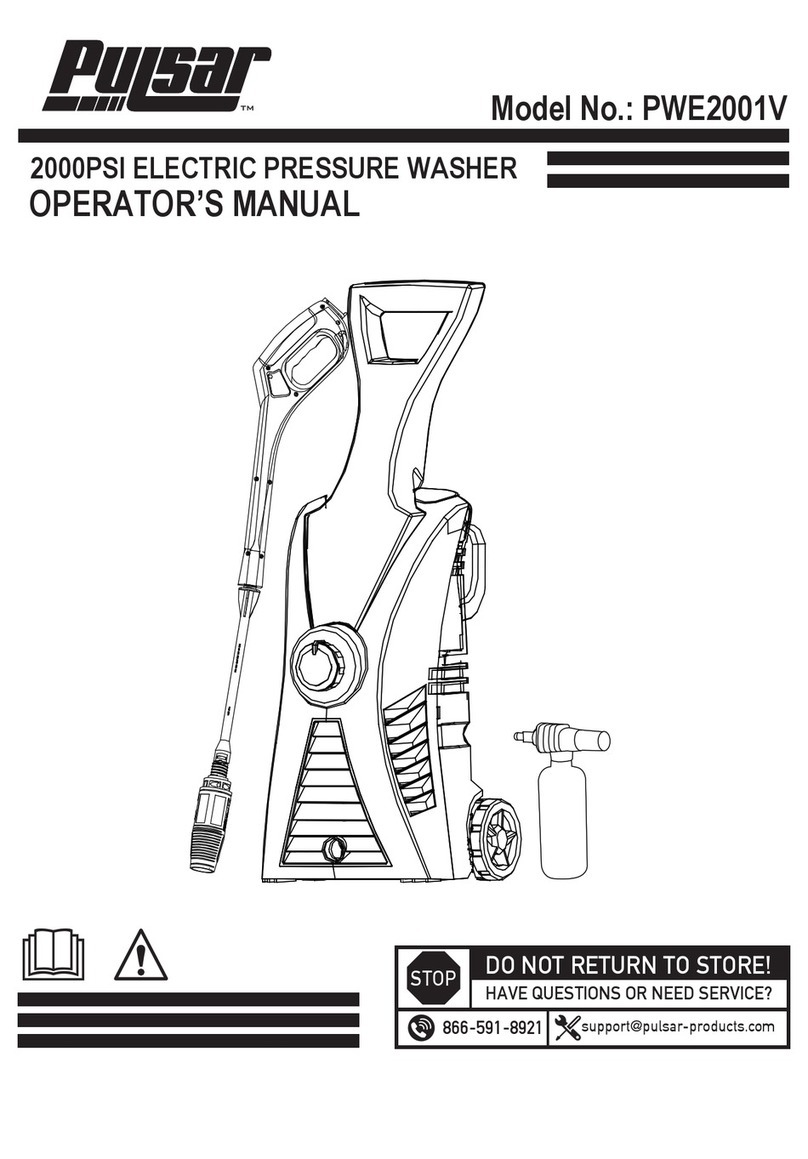

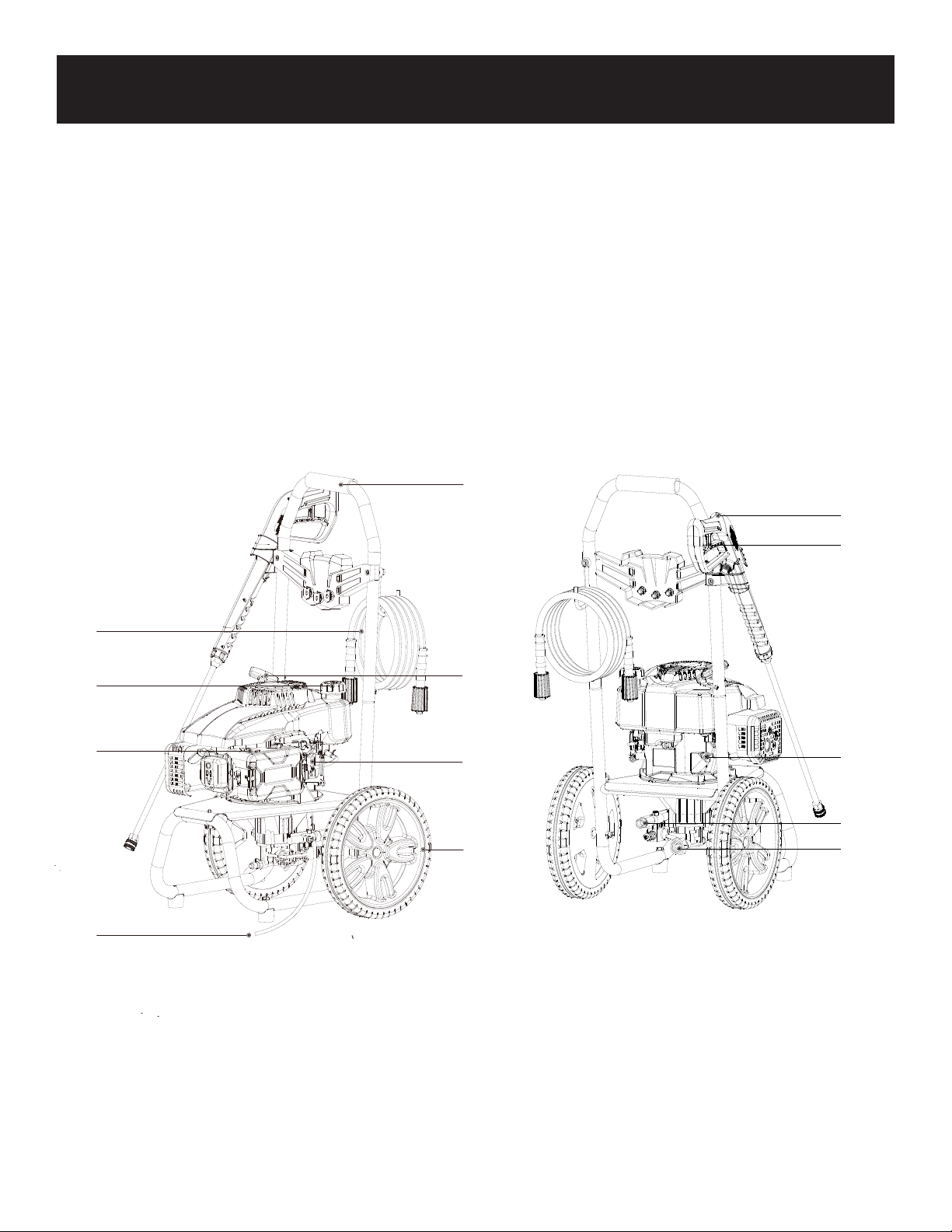

Pressure Washer Features....................................................................................................................................................7

Pressure Washer Parts Assembly........................................................................................................................................7

Pressure Washer Parts List ..................................................................................................................................................7

Assembly..............................................................................................................................................................................10

Packing List............................................................................................................................................................... 10

Unpacking................................................................................................................................................................. 10

Attaching Wheels...................................................................................................................................................... 11

Install Handle. ...........................................................................................................................................................11

Attaching Gun Hook and Pressure Hose Hook......................................................................................................... 11

Attaching Spray Gun.................................................................................................................................................12

Adding Engine Oil and Fuel ....................................................................................................................................... 13

Operation .............................................................................................................................................................................. 15

How to Start Pressure Washer.................................................................................................................................. 15

How to Turn Off Pressure Washer............................................................................................................................16

How to Use Spray Gun..............................................................................................................................................16

Using Spray Nozzle ..................................................................................................................................................17

How to Apply Detergent...........................................................................................................................................17

Maintenance .........................................................................................................................................................................18

Pre Operation Steps..................................................................................................................................................18

After Each Use..........................................................................................................................................................18

Maintenance Schedule..............................................................................................................................................18

Changing Oil.............................................................................................................................................................19

Engine Maintenance .................................................................................................................................................19

How to Store ............................................................................................................................................................20

Troubleshooting...................................................................................................................................................................21

Warranty ...............................................................................................................................................................................22

SAVE THIS MANUAL FOR FUTURE REFERENCE

This manual contains important information regarding safety, operation, and maintenance.