4. NAME OF PARTS: (FIG. 1、FIG.2)

5. PRODUCT DESCRIPTION

PURPOSE

The high pressure cleaner is designed to clean vehicles, machines, buildings, facades, etc.

in the private sector.

AREAS OF APPLICATION

Never use the machine in potentially explosive areas under any circumstances!

The operating temperature must be between 0 and +40 .℃

The machine consists of an assembly with a pump, which is encased in a shock absorbing

housing. For an optimal working position the machine comes with a lance and a non-slip

handle grip, whose shape and configuration comply with the applicable regulations.

Do not cover or modify the lance or the spray nozzles in any way.

The high pressure cleaner is designed to be used with cold or lukewarm (max. 60 ); higher℃

temperatures can damage the pump.

Do not use water that is dirty, gritty or contains any chemical products, as these could impair

operation and shorten the life of the machine.

Accessories can be used to carry out work with foam cleaners, sand spraying.

6. ASSEMBLY

Position the washer as NEAR as possible to the water supply.

The washer must be used standing on a secure, stable, positioned as shown. FIG.3.

Fit the lance into the gun and rotating it until the two parts are completely locked FIG. 4.

Connect the gun to the high pressure hose FIG.5.

Connect the high pressure hose to the water outlet on the washer FIG.6.

Connect the water supply hose to female coupler FIG.7, then connect to the water inlet of

the washer. The supply hose must have an internal diameter of at least 13mm (1/2 in.) and

must be reinforced. The water supply must be at least equal to the washer delivery capacity.

NOTE: The machine not suitable for connection to the potable water main (FIG. 14).

WARNING

The intake water temperature must not exceed 40℃. The water supply must not exceed 0.7 MPa.

CAUTION

The washer must only be used with clean water; use of unfiltered water of corrosive

chemicals will damage the washer.

Push the motor switch to “OFF” position FIG. 9.

Check that the electrical supply voltage and frequency (Volt/Hz) correspond to those specified

on the washer rating plate. If the power supply if correct, you may now plug in the washer.

7. OPERATION

Turn on the water supply tap fully.

Release the safety lock FIG.8, then press the trigger for a few seconds to allow air to

escape and to discharge residual pressure in the hose.

Keeping the trigger pressed, push the switch to start the motor FIG.9.

When re-starting the motor, always keep the trigger pressed.

NOTE:

THE MOTOR ONLY RUNS WHEN THE TRIGGER IS OPERATED.

CORRECT USE OF STANDARD ACCESSORIES

The washer is equipped with the adjustable nozzle.

Jet adjustment from pencil to fan FIG. 10.

WARNING: DO NOT ADJUST THE NOZZLE WHILE THE TRIGGER IS SQUEEZED.

RECOMMENDED CLEANING PROCEDURE

Dissolve dirt by applying detergent with the fan jet to the dry surface. On vertical surfaces,

work from the bottom upwards. Leave the detergent to act for 1 to 2 minutes, but do not

allow to dry out. Apply the high from the surface, working from the bottom upwards.

Avoid allowing the rinsing water to run on to unwanted surfaces.

STORAGE (FIG.11 – FIG. 13)

Switch off the washer.

Turn off the water supply tap.

After use, the detergent residuals should be removed from the tank.

Discharge residual pressure by pressing the trigger until no more water comes out of the

lance nozzle.

Engage the gun safety lock.

Remove the plug from the socket.

Operate the washer with non-corrosive/ non-toxic antifreeze before storing for the winter.

WARNING:BEFORE REUSING, COMPLETELYFLUSH THE UNIT OUT WITH PLAIN WATER.

ANTI-FREEZE CAN DAMAGE PAINTWORK SO YOU MUST ENSURE THERE IS NO ANTI-

FREEZE LEFT IN THE SYSTEM BEFORE USING IT AGAIN.

8. MAINTENANCE

CAUTION

Before working on the washer, disconnect the lug from the power supply socket.

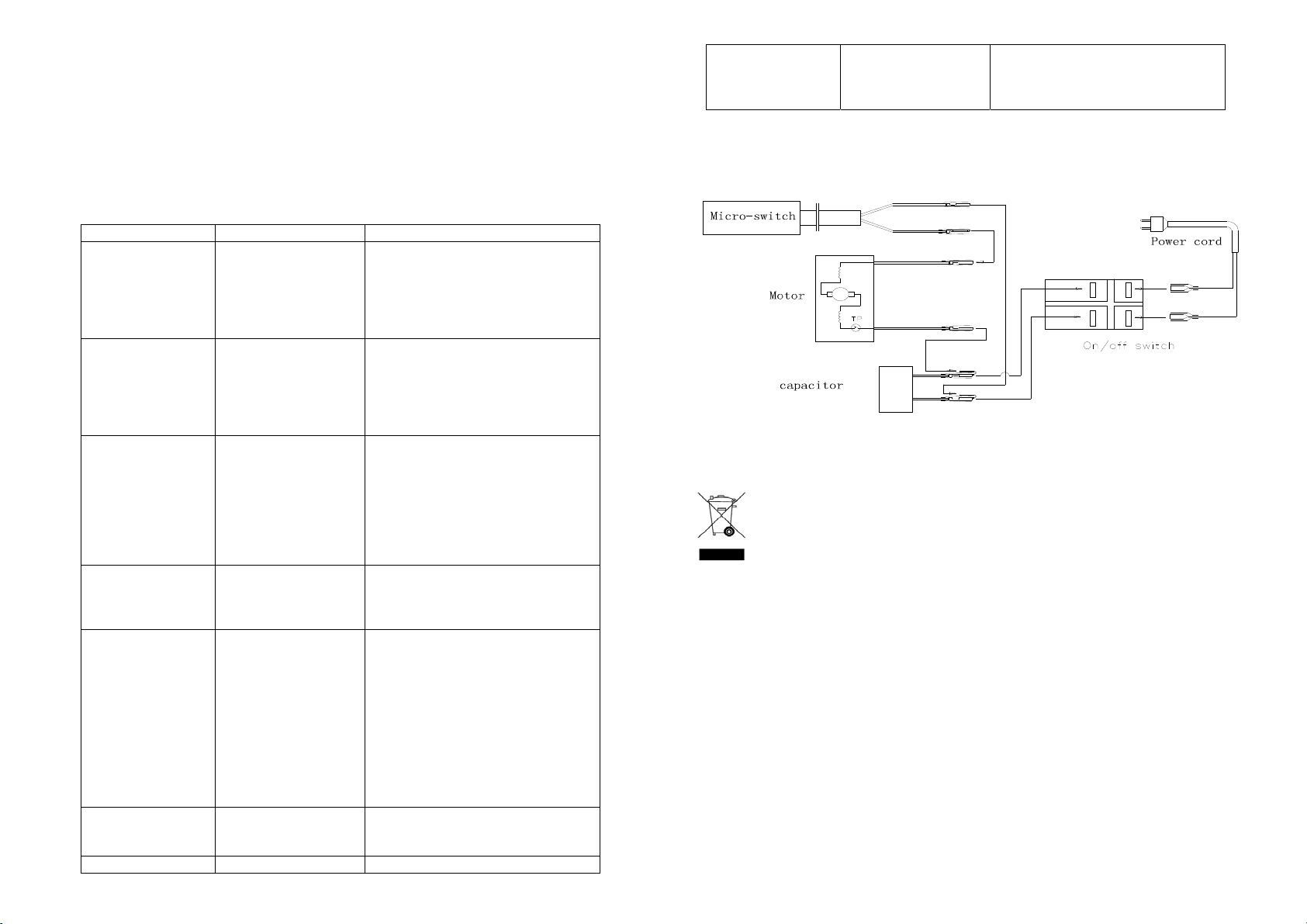

1.Powr cord 7. Gun lock 13. Wheel

2.Water outlet 8. Trigger 14. Warning label

3. On/Off switch 9. High pressure hose 15. Rating label

4. Mid lance 10. Spray lance

5. Spray gun 11. Water inlet

6. Handle 12. Hose hook