4

CONTENTS

Chapter 1 Start Here................................................................................................................6

About this Manual ...............................................................................................................6

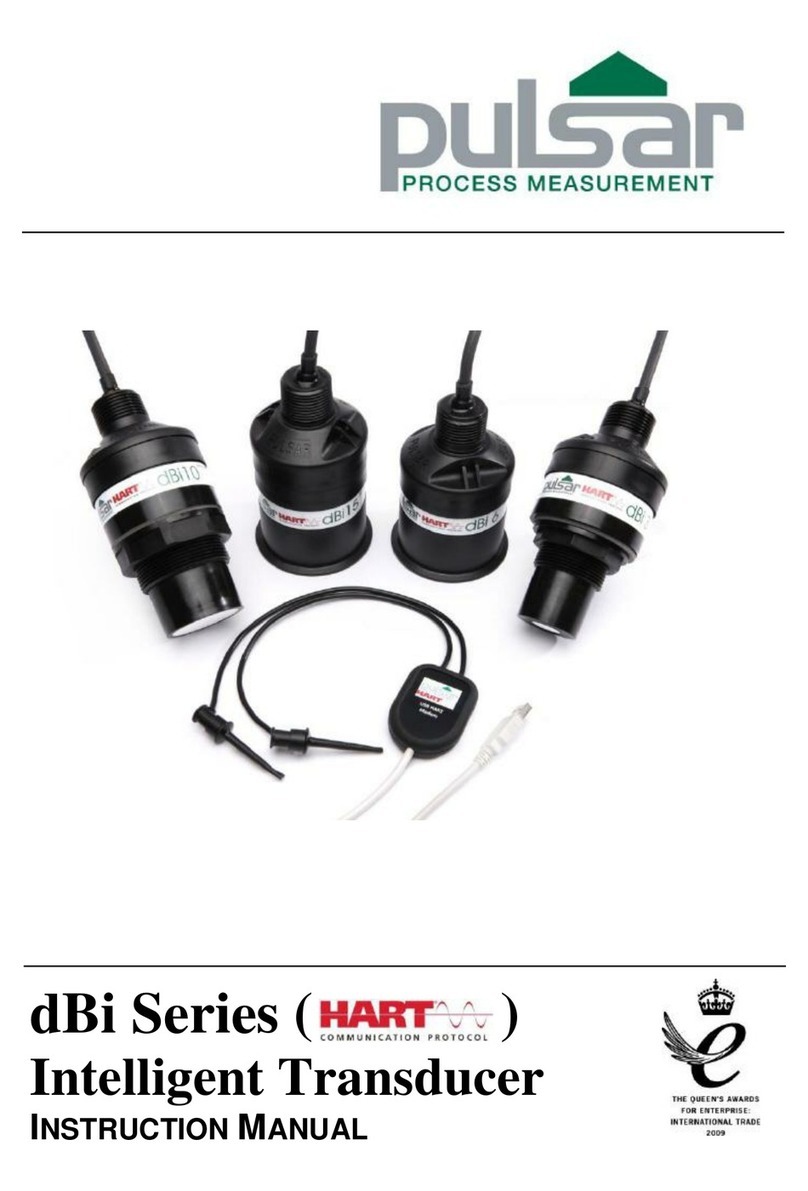

About the dBi-M...................................................................................................................7

Product Specification..........................................................................................................8

EU & UK Certificate of Conformity............................................................................. 10

Chapter 2 Installation........................................................................................................... 11

Unpacking............................................................................................................................11

Power Supply Requirements......................................................................................... 11

Location ................................................................................................................................11

Dimensions ..........................................................................................................................12

Outdoor and Open Vessel Installation ..................................................................... 14

Closed Vessel Installation ..............................................................................................15

Cable ...................................................................................................................................... 16

Hazardous area location................................................................................................. 17

Preparation for Operation ............................................................................................. 18

Maintenance ....................................................................................................................... 18

Parameter Defaults........................................................................................................... 18

Chapter 3 Getting Results With dBi-M Transducers................................................19

Setting up Your Application.......................................................................................... 19

Resetting Factory Defaults............................................................................................. 20

Chapter 4 dBi-M PC Software........................................................................................... 21

dBi-M RS485 Connector.................................................................................................21

Opening dBi-M PC............................................................................................................22

dBi-M PC Opening Screen.............................................................................................23

Menu Strip ........................................................................................................................... 23

Shortcut Icons..................................................................................................................... 27

Toggle Parameter List .....................................................................................................29

Main Screen Selection Tabs ..........................................................................................29

Main Screen......................................................................................................................... 30

Common Parameters.......................................................................................................34

Progress Bar ........................................................................................................................ 37

Cursor Position...................................................................................................................38

Transducer ........................................................................................................................... 39

Chapter 5 Parameter Guide ...............................................................................................40

Application...........................................................................................................................40