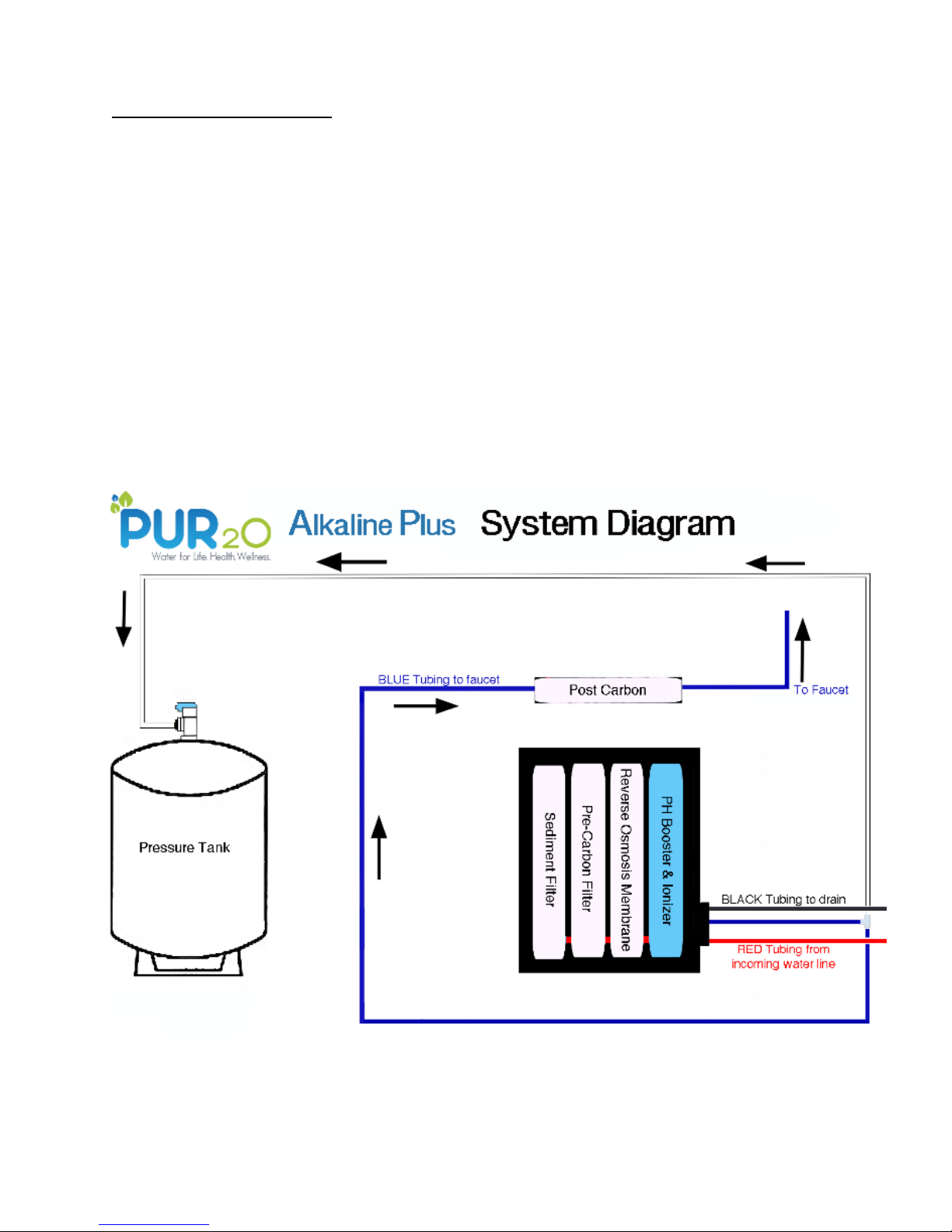

Inlet Water Supply

CAUTION: ONLY USE COLD WATER LINE. IF YOU CANNOT TELL WHICH LINE IS

THE COLD, TURN ON WARM WATER AND FEEL FOR WARMTH.

1 - Locate the cold water line and shut-off valve for faucet.

Shut off water supply. Turn cold water on at sink to release

pressure.

2 - From parts bag, locate: ⅜” x ¼” x ⅜” ANGLE SUPPLY VALVE.

3 - Disconnect ⅜” tubing from existing cold water shut-off. Insert ANGLE VALVE

on the male thread of the existing cold water supple valve. Now, fasten the loose

⅜” tubing to the TOP of the ANGLE VALVE.

4 - Connect ¼” tubing to the port in the ANGLE VALVE.

5 - Turn OFF BLUE VALVE.

6 - TURN ON cold water supply. making sure there are no leaks.

NOTE: THE ABOVE INSTALLATION STEPS ARE FOR COPPER AND PLASTIC

PLUMBING INSTALLATION ONLY. TO INSTALL IN IRON PIPE, YOU WILL NEED TO

DRILL A HOLE FOR THE PIERCING POINT.

System Start-Up

1 - Turn on cold water supply.

2 - Make sure the tank ball valve is in the OFF position.

3 - Turn ON dedicated faucet, wait until the water flows to a steady trickle.

4 - Turn off the faucet - this will allow the system to PRESSURIZE. At this time,

check the system for leaks.

5 - Turn the tank ball valve to the ON position.

6 - It will now take several hours (2-3) for the storage tank to completely fill,

depending on the local water pressure.

7 - After the tank is filled, turn on the dedicated faucet and allow the pressure

tank to completely drain. This will take about 5 minutes.

CAUTION: DO NOT DRINK THE WATER FROM THE FIRST TANK PRODUCED BY

YOUR NEWLY PURCHASED SYSTEM.

8 - Turn OFF the dedicated faucet.

9 - REPEAT Steps 7 & 8.

10 - Wait for the pressure tank to fill again.

You are now ready to enjoy the water.

7 - Check for leaks for the first several days and periodically thereafter.

8 - You may notice that the water may be milky colored during the first week.

This results from air bubble in the water. It is normal and safe.

-8-