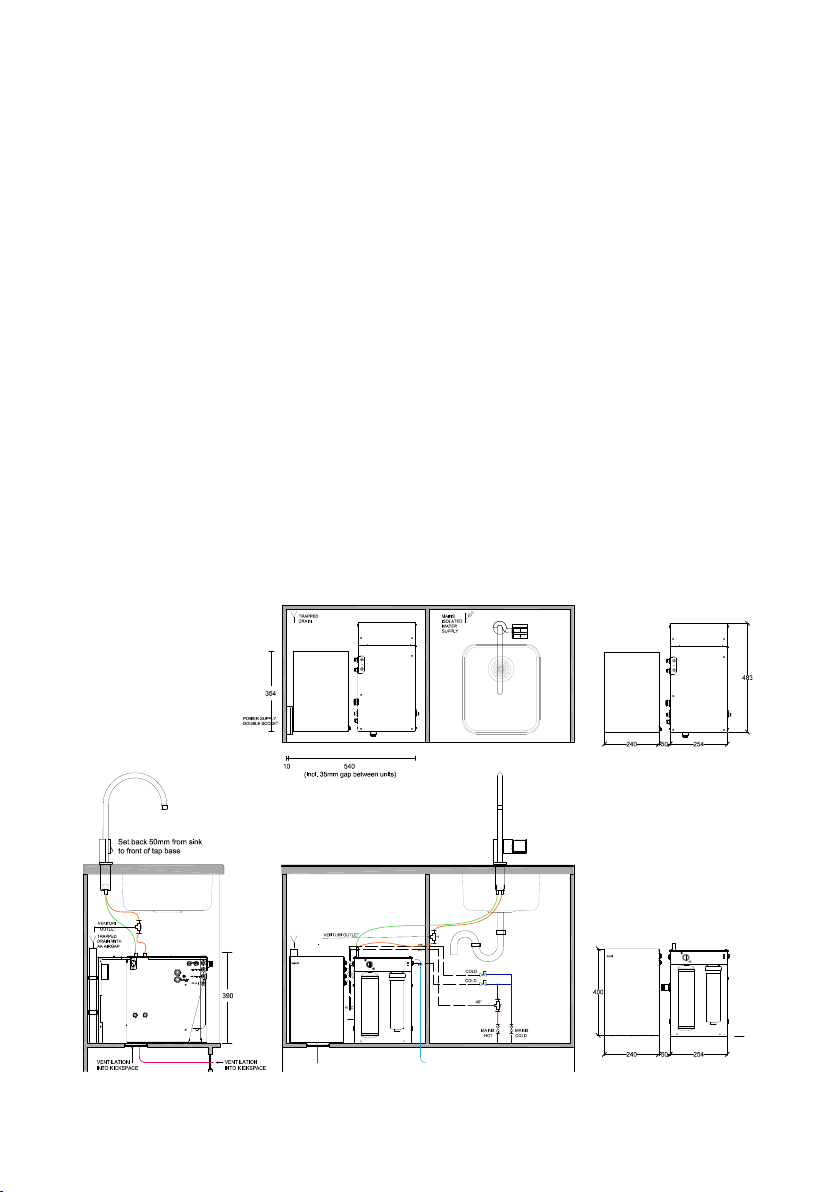

The Boiler control units and Chiller

Carbonator modules must sit underneath

the tap or in an adjacent cupboard to the

tap location.

This is because the tap has a

communication cable that plugs into

the Q553-B (boiler control) that cannot

be stretched. Most models will fit into

a standard 600 cupboard. The Infinite

range(653) requires a 650 or 700

cupboard as minimum space.

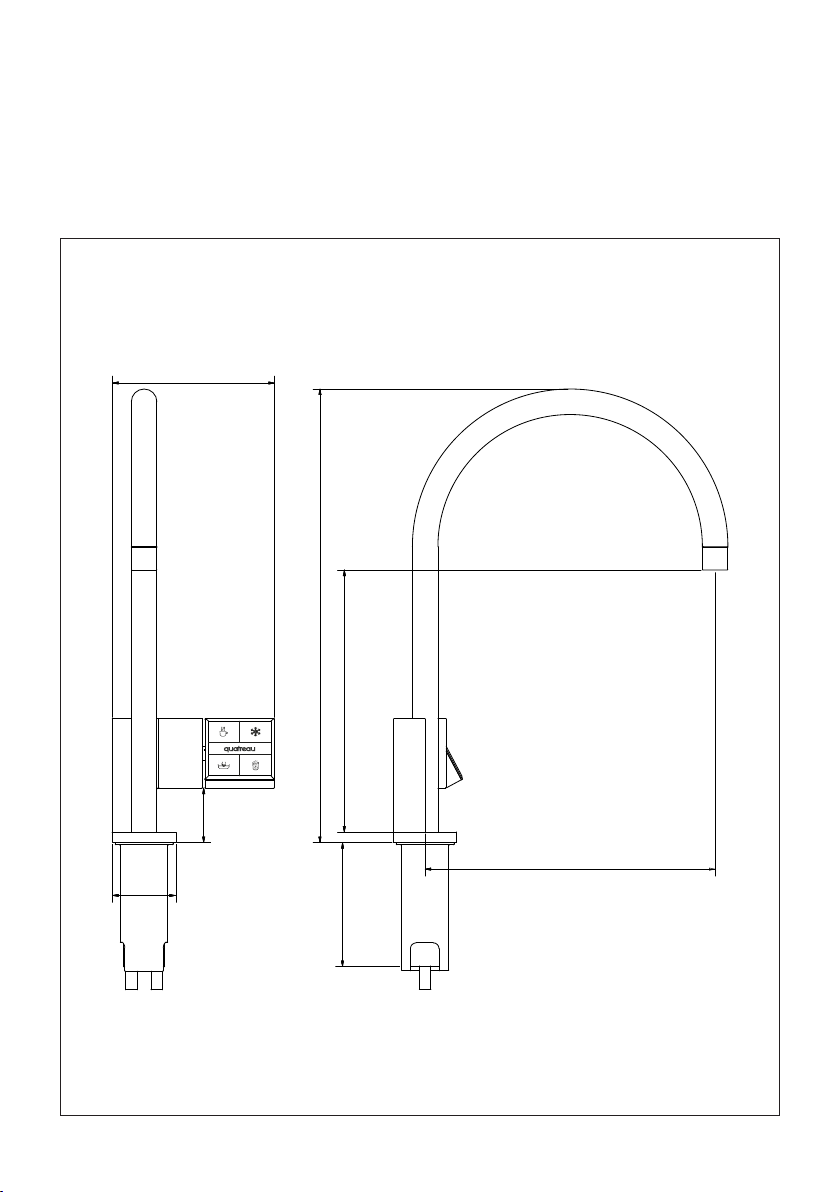

There are 3 types of Quatreau Tap (faucet)

1. Quatreau Touch™

2. Quatreau SmartTap™*

3. Quatreau SmartTap™ with integrated

driptray*

1. INSTALLING THE QUATREAU TOUCH™

The Touch requires a 40mm hole cut into

the surface behind the sink or drainer it is

going to be used with.

Depending upon the surface you will

need special cutting equipment. For

granite or marble a diamond tipped

core bit will be required. For wood or MDF

or polymer type surface a wood bit will

normally be adequate. Always check with

the worksurface manufacturer and ask

what type of bit can be used.

Decide where the tap is going to sit. Note

that the control panel is on the right-hand

side of the tap. Ensure that the location

you choose is suitable and that you can

reach the controls without needing to

stretch.

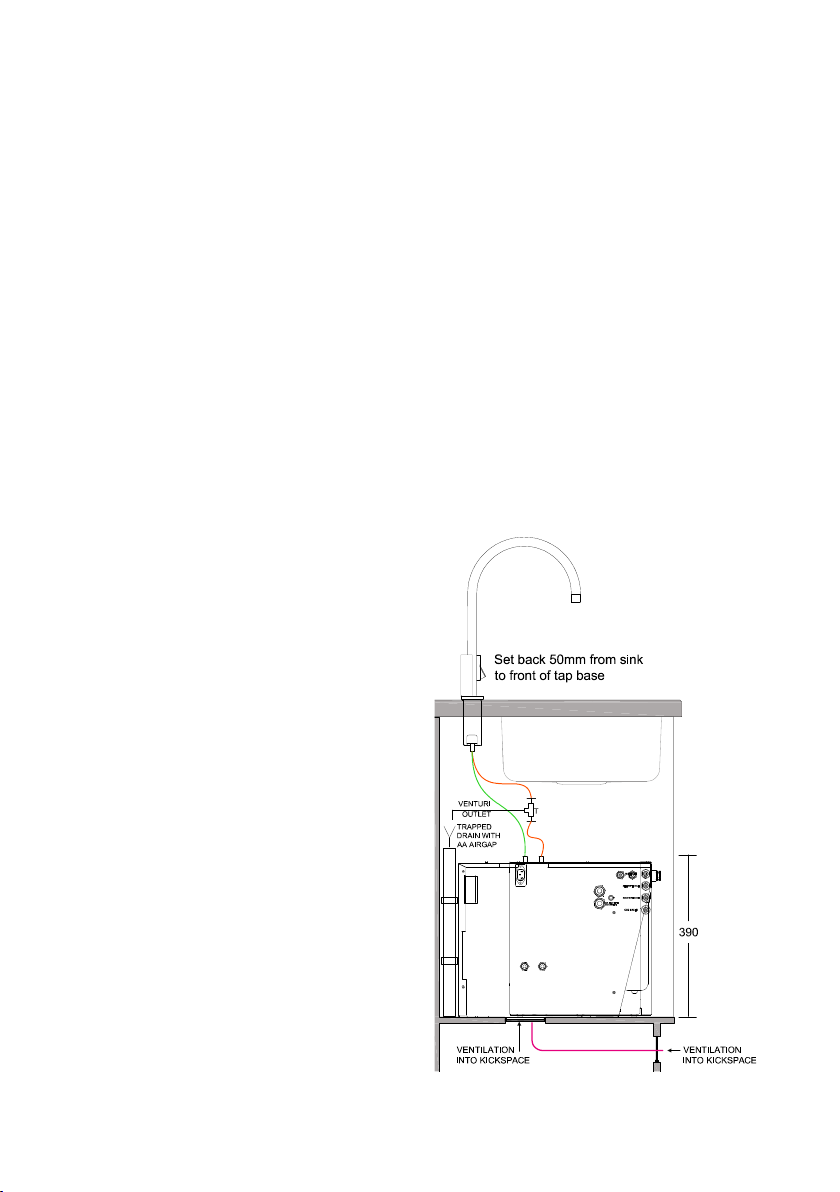

We typically set back approximately

50mm from the back edge of the sink.

Your kitchen design will of course dictate

whether this is possible.

Before you start cutting ensure that you

have set up a jig or a template device to

prevent the drill bit moving when you start

the cut.

Once the hole is prepared, remove any

rough edges or bits of wood and place

the tap carefully into the hole ensuring

that the comms cable is dropped into the

hole first to prevent damage.

Using the washer and fixing bracket

provided, you can now fix the tap in

place underneath the work surface.

Be careful to locate the comms cable

into the groove behind the tap base

then slide the washer up over the base

followed by the fixing bracket. This will

screw onto the thread on the tap base.

Ensure that the comms cable is not

damaged as you spin the bracket

clockwise until it is almost at the top of the

thread.

At each side of the fixing bracket you will

see a threaded hole. Using the two bolts

provided thread up into these holes until

tight against the washer above. With a

flat head screw driver, tighten each one

gently.

Now position the tap so that the control

panel faces forward towards the user

position (180degrees to the sink). Now you

can tighten the nuts until you have a firm

fixing on both sides.

The comms cable hangs down and will

connect into the QT553-B unit when it

is installed. It’s essential that the 553-B

is located close to this cable without

causing it to stretch.

*See the Quatreau SmartTap version™of this document for installaiton details.

IN STA LL AT IO N