05. Description of sensor operation

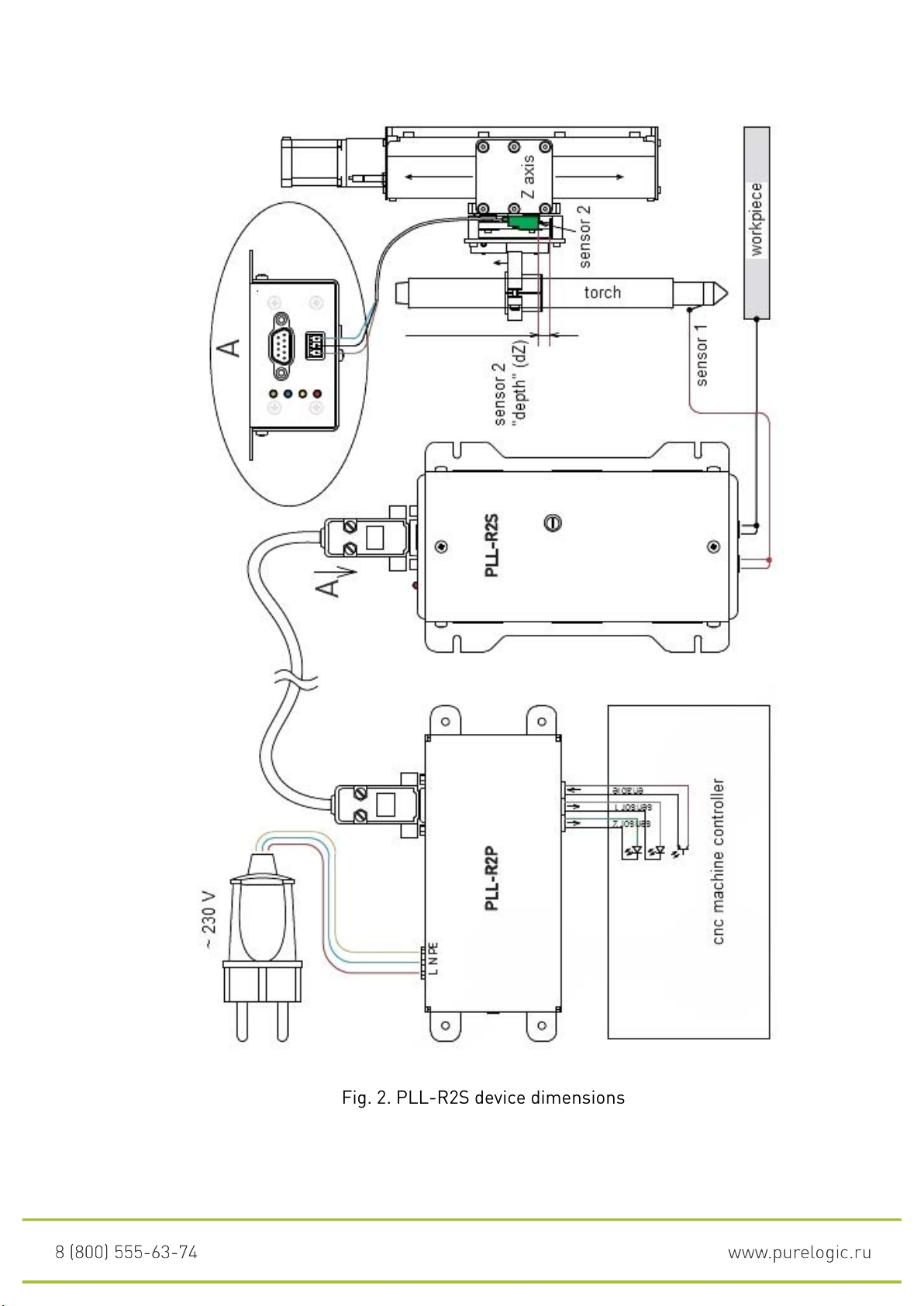

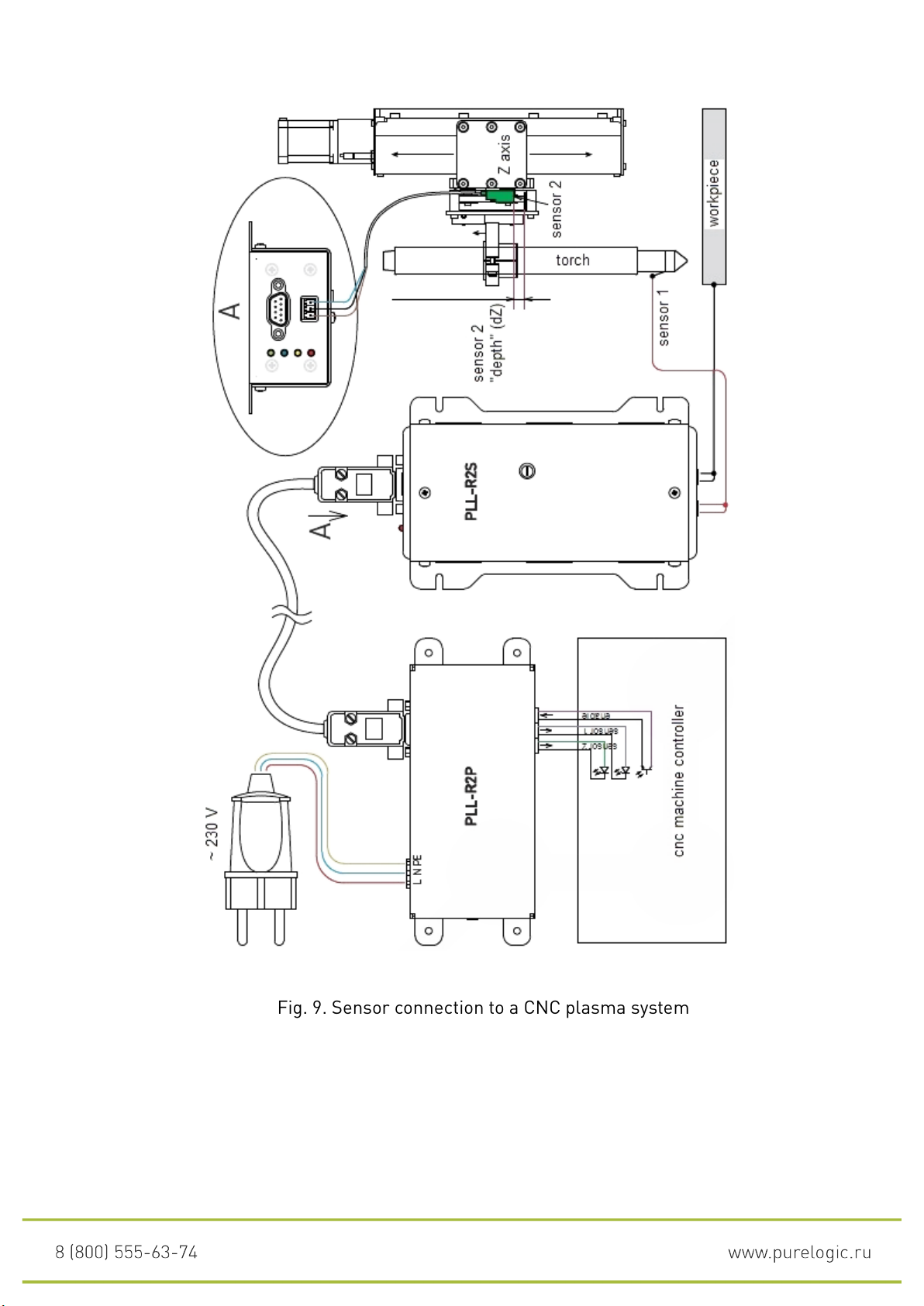

An ohmic sensor allows to detect the workpiece surface when the torch moves down.

When the torch cap touches the workpiece, the “Sensor 1” signal appears. If for any reason

the first sensor does not work and the Z axis continues moving down, then dZ mm (Fig. 9)

will trigger sensor 2 and two signals will immediately appear at the output: “Sensor 1” and

“Sensor 2”. In this case, to obtain the torch height above the workpiece surface, it is

necessary to correct the Z coordinates by the distance dZ.

The sensitivity control is designed to reduce the sensor sensitivity in the case of strong

interference, which can cause false activation, or to increase the sensitivity in the case of

contaminated workpiece.

06. Warranty

Warranty service life is 12 months from the purchase date.

The warranty is only preserved if operation and scheduled maintenance conditions are

observed.

1. General provisions

1.1. If the goods is purchased as component parts, Seller shall guarantee operability of

each component part individually, but is not responsible for the quality of their joint

operation (incorrect selection of component parts. In case of any questions you can consult

the company’s specialists).

1.2. Seller does not provide any warranty for compatibility of the purchased goods and the

goods possessed by Buyer, or purchased by them from any third parties.

1.3. Specifications and configuration of the product can be changed by manufacturer

without prior notice due to continuous technical improvement of the products.

2. Conditions for access to warranty service

2.1. The goods is accepted for warranty service in the same configuration in which it was

purchased.

3. Warranty service procedure

3.1. The warranty service is carried out by testing (checking for) the declared malfunction

of the product.

3.2. The warranty service is carried out if the malfunction is confirmed.

4.The warranty does not cover glass, electric lamps, starters and consumable materials,

and:

4.1. any goods damaged due to improper transportation and storage conditions, incorrect

connection, offdesign operation, or in conditions not stipulated by the manufacturer

(including temperature and humidity beyond recommended range), damaged due to effect

of exterior circumstances (power supply voltage surges, natural disasters, etc.), and

mechanically or thermally

damaged goods.

4.2. Goods with traces of effect and (or) ingress of foreign objects, substances (including

dust), liquids, insects and those with extraneous texts.

4.3. Goods with traces of unauthorized tampering and (or) repair (tampering signs,

primitive soldering, traces of component replacement, etc.).

4.4. The goods having self-diagnostic means indicating improper operation conditions.