AWS1100 Wet Sander Manual 3

Copyright PushCorp, Inc. 2000. All rights reserved.

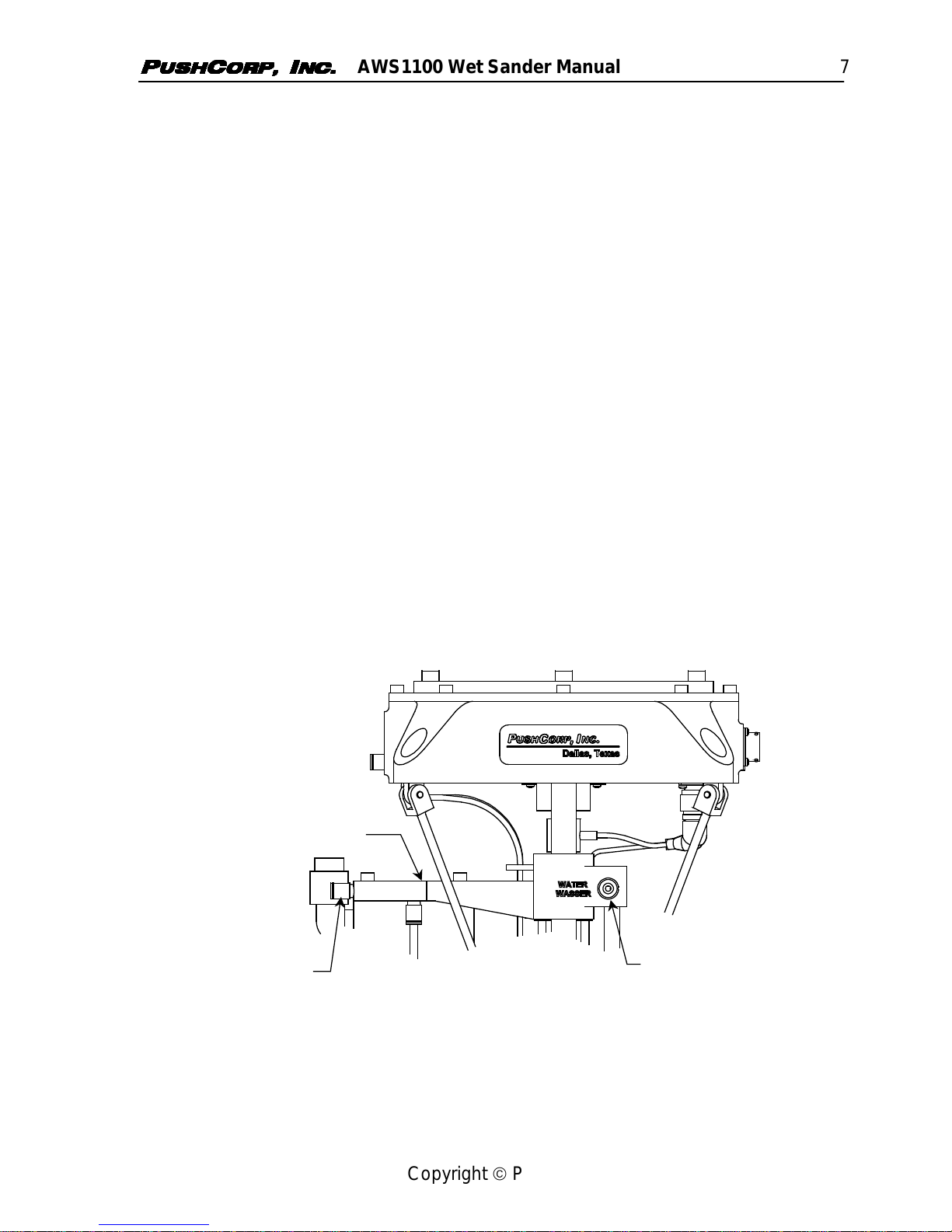

2.0 General Overview

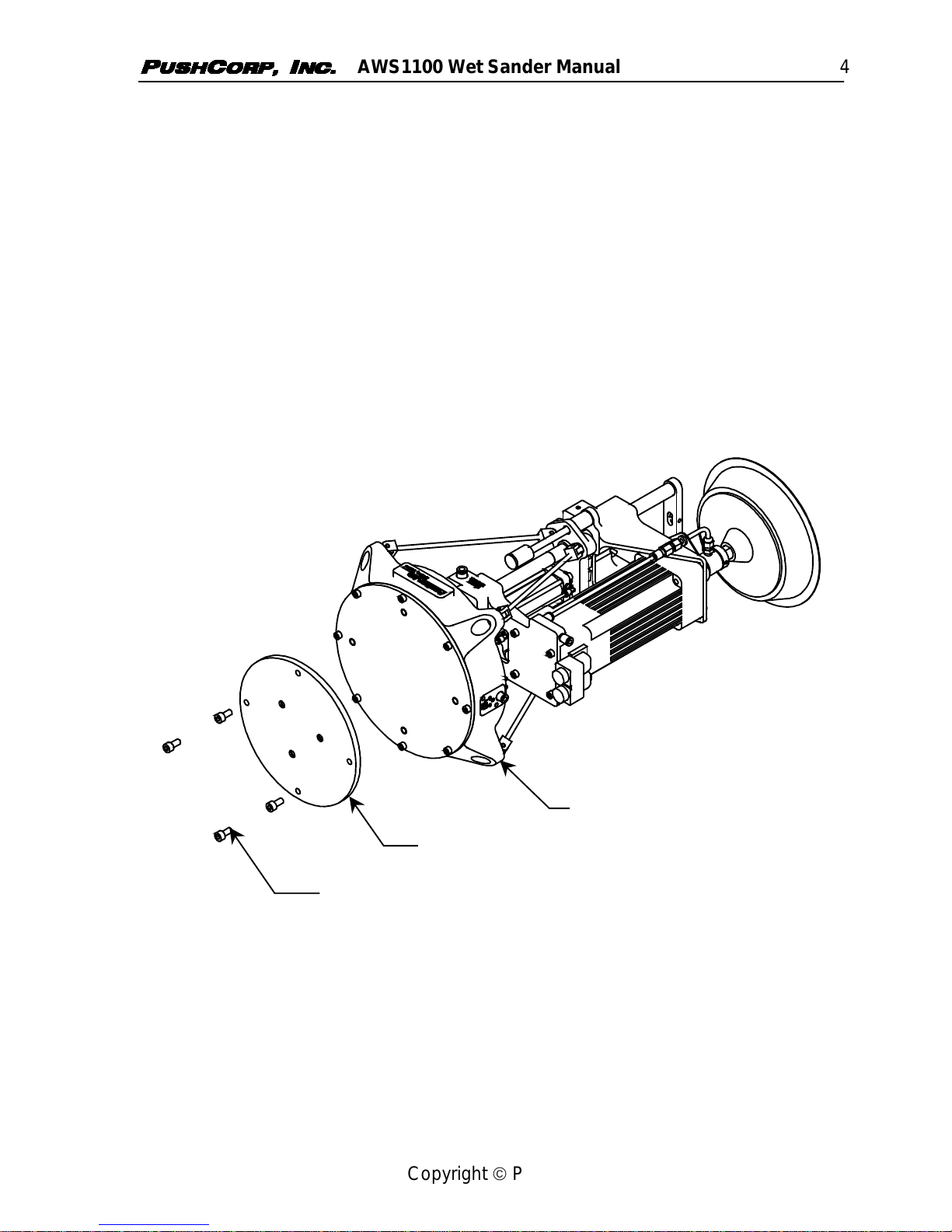

The PushCorp, Inc. AWS1100 Wet Sander and FCU1000 Active Compliance

Controller (US Patent No. 5,448,146) provide a superior robotic surface finishing

system. The AWS1100 is an end of arm robotic device specifically designed to

perform wet sanding operations. The Wet Sander system enables a robot to

manipulate an abrasive media over any contoured surface with an extremely precise,

consistent, compliant force. This unique capability gives the robot the ability to excel

in a traditionally expensive and inconsistent manual process. The Wet Sander

coupled with a robot delivers results that are virtually impossible to duplicate with a

manual operation.

To achieve this superior performance, the AWS1100 Wet Sander utilizes PushCorp

patented active force control technology. This technology is realized through the use

of a pneumatic actuator to provide the sanding force and a load-cell force sensor to

provide closed-loop feedback to the control unit. The pneumatic actuator provides the

force and necessary compliance by moving the sanding motor along linear rods.

These linear rods allow a 3.0 inch (80mm) stroke enabling the sanding pads to remain

in contact with the part, and apply the correct force, regardless of any robot/part

misalignment. Also, the AWS1100 contains an accelerometer that monitors the

spacial orientation and allows the unit to automatically compensate for gravitational

and inertial effects to maintain the desired sanding force. Finally, a linear

potentiometer, located within the pneumatic actuator, senses the position of the Wet

Sander motor along the linear rods.

The AWS1100 has several unique features to endure the harsh conditions found in a

typical wet sanding environment. A primary feature is that AWS1100 is water-

resistant, allowing the tool to be washed down. The tool’s main linear bearings are

hydrostatic and float on Stainless Steel linear rods using water pressure. This method

has been chosen to resist rust and corrosion while maintaining the low friction

required for precise force control. All of the electronics are sealed in the base housing

to prevent any water contamination.

The AWS1100 is equipped with a variable speed servo sanding motor. The motor is

controllable over a -6200 to +6200 rpm speed range. The servo sanding motor is also

equipped with an integral water feed-through to supply the abrasive pad with flooding

capability.

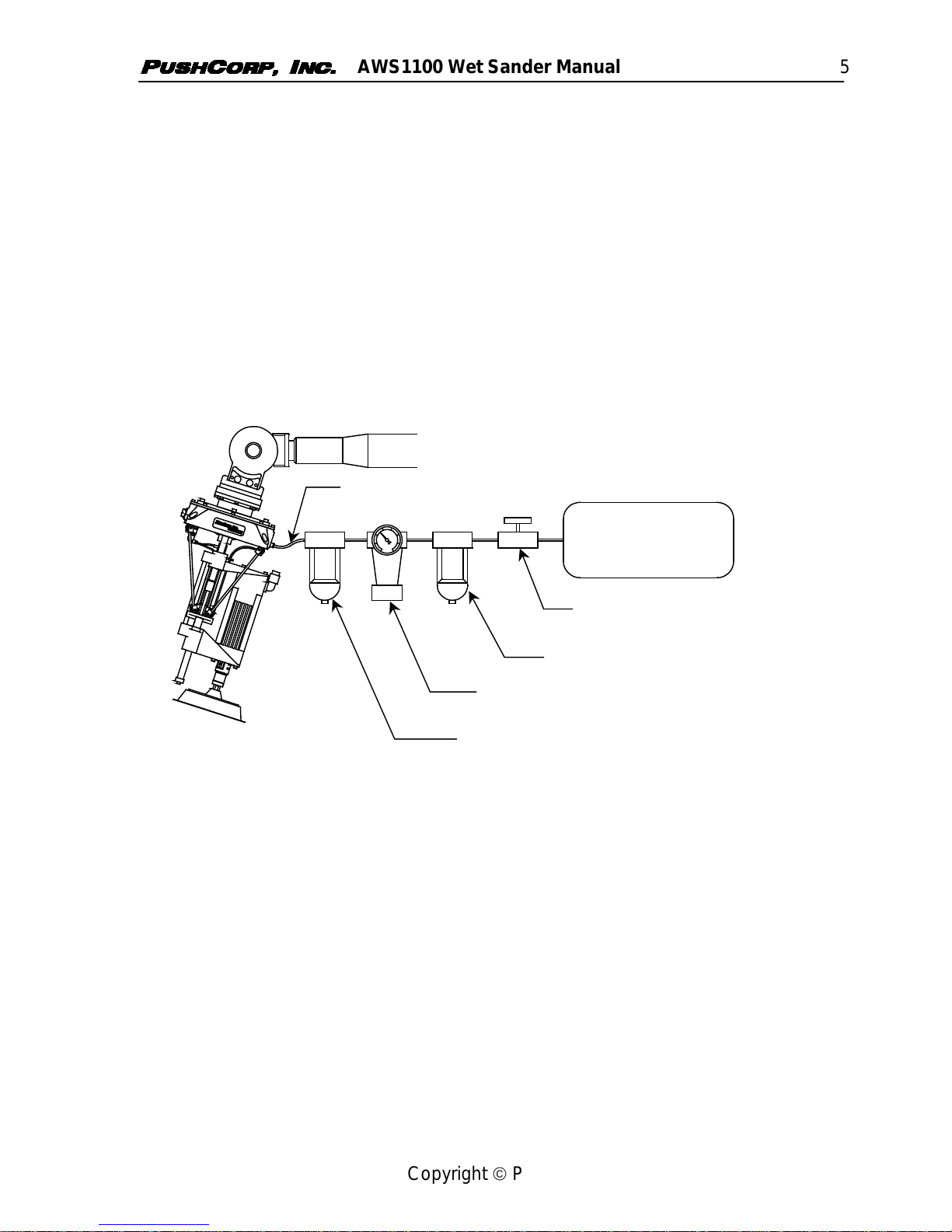

To control the AWS1100 Wet Sander the FCU1000 Active Compliance Controller

must be used. The unit contains a high-speed microprocessor executing proprietary

control algorithms. The microprocessor controller provides several advanced features

including automatic motor/tool weighing, automatic motor weight/gravity

compensation, and automatic compensation of acceleration induced forces. To

facilitate system integration, a remote host computer or PLC controller can be

interfaced through high level communications including RS-232 serial, 24 VDC

parallel, or analog interfaces.