Contents

III

3 General Technical Description

3.1 Machineversions 3 — 1.....................................

3. Machine designation 3 —. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Machinemodel 3 —......................................

3.4 Machinenumber 3 —.....................................

3.5 Summary 3 — 3............................................

Machine 3 — 3..........................................

Enginecompartment 3 — 4...............................

3.6 Technicaldata 3 — 5.......................................

Dimensions 3 — 5.......................................

Weight 3 — 5...........................................

Chassis 3 — 5...........................................

Tyres 3 — 5.............................................

Performancedata 3 — 6..................................

Fluidcapacities 3 — 7....................................

3.7 Ratingplate 3 — 8.........................................

3.8 Soundpowerlevel 3 — 9....................................

3.9 Safetyequipment 3 — 10.....................................

EMERGENCY STOP button 3 — 10. . . . . . . . . . . . . . . . . . . . . . . . .

Hoodsafetydevice 3 — 11................................

Protectivegrilles 3 — 11...................................

Safetyswitch 3 — 11......................................

3.10 Functional description 3 — 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

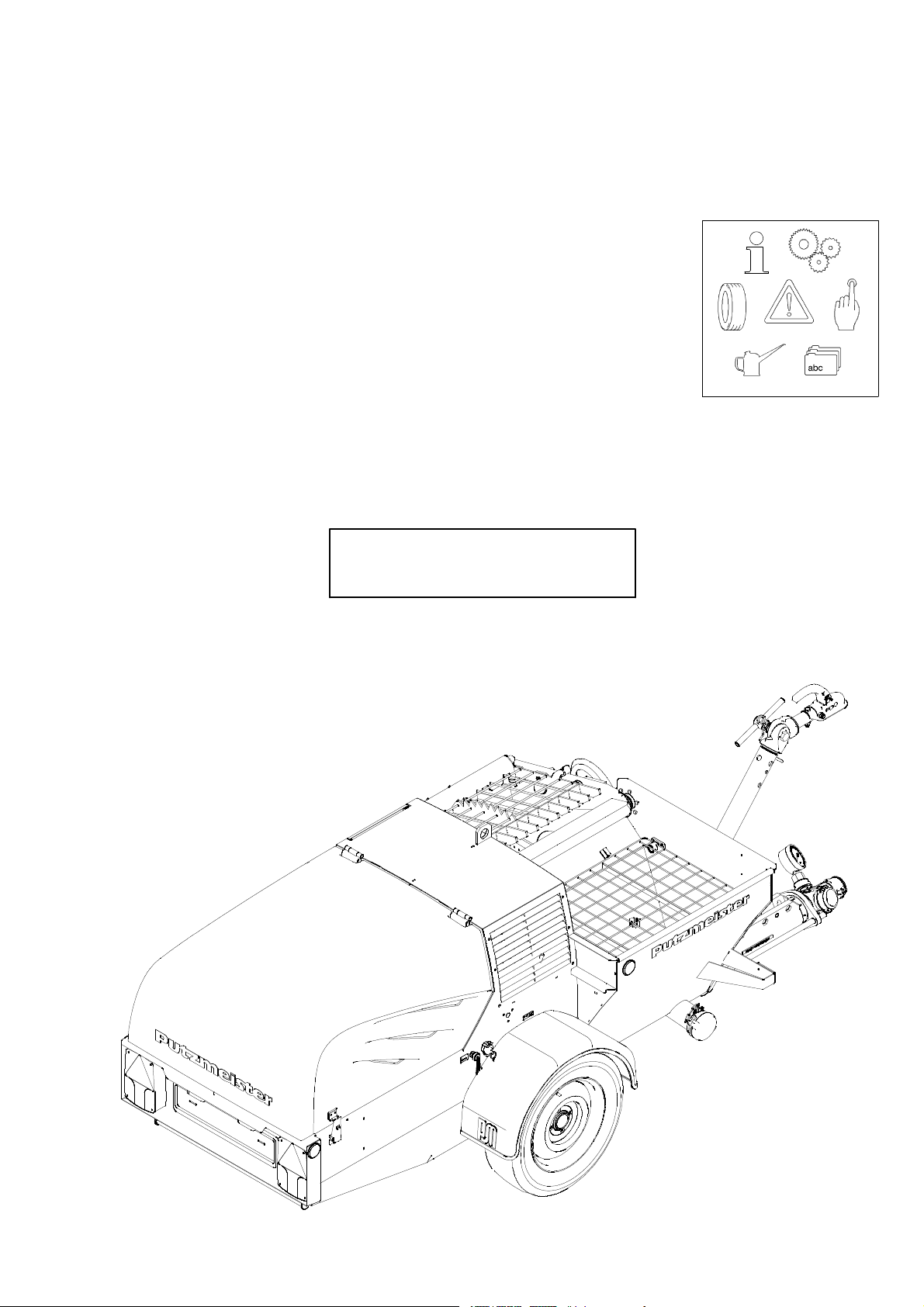

General set-up of the machine 3 — 1. . . . . . . . . . . . . . . . . . . . . .

3.11 Controlcabinet 3 — 13.......................................

3.1 Engine 3 — 15..............................................

3.13 Augerpump 3 — 16.........................................

3.14 Hydrauliccontrol 3 — 17.....................................

Hydraulic control block SP11 3 — 18. . . . . . . . . . . . . . . . . . . . . . . .

3.15 Compressor 3 — 19.........................................

3.16 Airvalvefitting 3 — 0.......................................

3.17 Spraygun 3 — 1...........................................

3.18 Dust extraction (option) 3 —. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.19 High-pressure cleaner (option) 3 — 3. . . . . . . . . . . . . . . . . . . . . . . . .