3

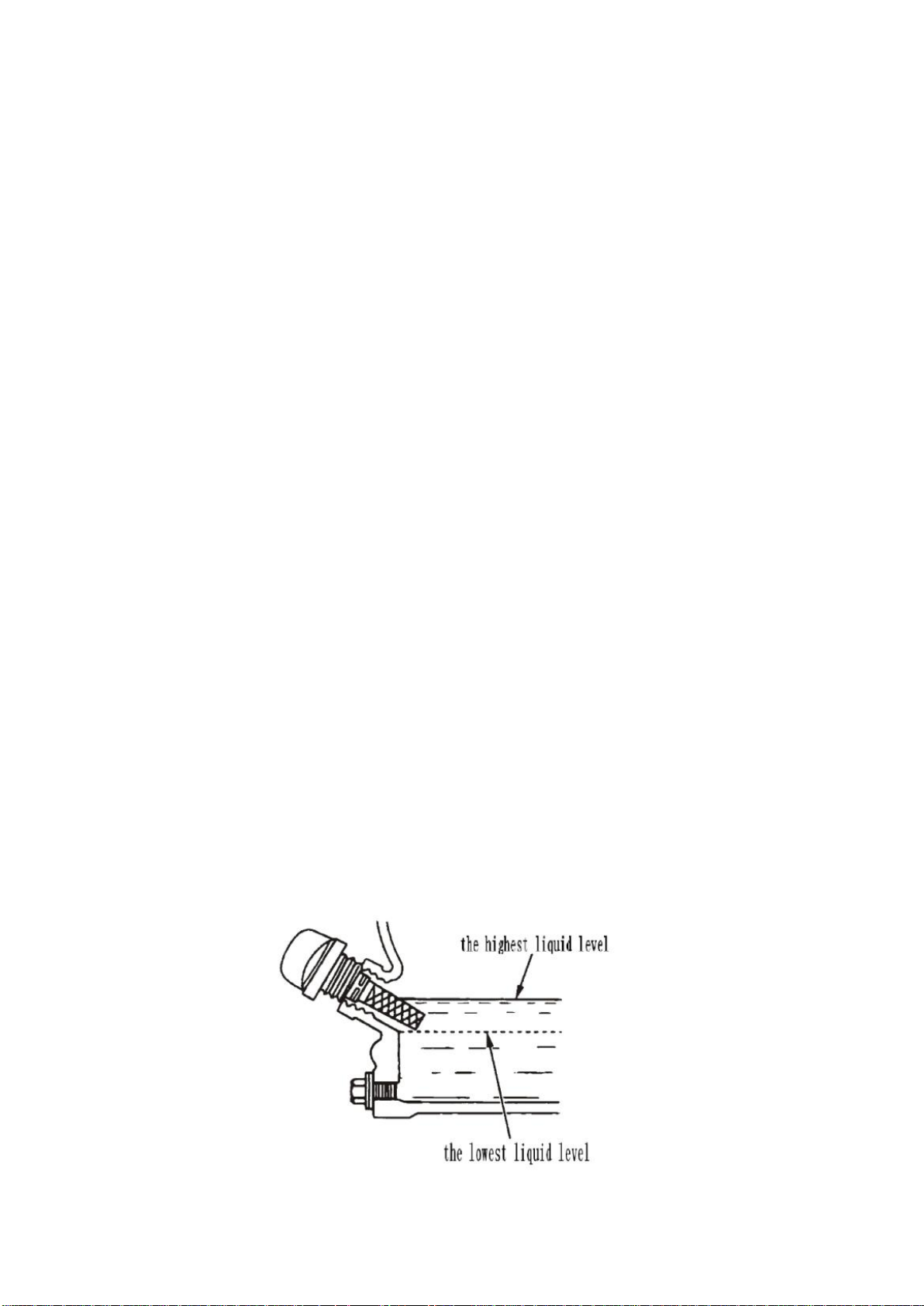

1)Remove the oil feet, and wiped the oil.

2)Feet into the oil filler, do not tighten it, check oil level.

3)If the oil-foot oil is not stained, indicating that the oil level is too low, then you should add the

recommended oil to the fuel filler

4)Replace the oil-foot .

Notice: it would damage the engine if you run the generator when the oil level is too low.

3. Hand-pulling the starter 2 to 3 laps to check whether it is in normal compression

Ⅲ.Start, Stop and Storage

1. Turn on the gas valve and ignition switch, and pull the choke to the closed position

2. Pull the starter rope slowly several times, and then quickly tug starter rope, open the choke immediately

after starting the engine.

Notice:

Keep the generator running for 3~5minutes without load, and check weather there are parts loose, any

oil leakage or governor failure. By listening auscultation to check for percussion, loosen and other

abnormal noises, if found, you should stop the generator and check.

Suddenly increase the load after starting is prohibited, for it would damage the spare parts.

3. Stop Gradually lifted load, and keep the generator running 4 to 5 minutes without load to cooling the

engine, then turn off the gas valve and ignition switch for stopping the engine.

Notice:

Suddenly stop the generator when it is running with heavy load is prohibited, for it would damage the

spare parts.

4. Storage If the generator needs long-term storage, you should keep it according to the bellows t o

prevent rust:

1) Remove the engine oil and dust on the engine surface.

2) Remove the spark plug, drop 20~25 drops engine oil for lubrication from the spark plug hole to the

cylinder, turn the crankshaft for a few laps, then put the piston on the top position where it walks, fit on the

spark plug and clean the generator surface.

3) Pack in poly bag and place in dry and ventilated place