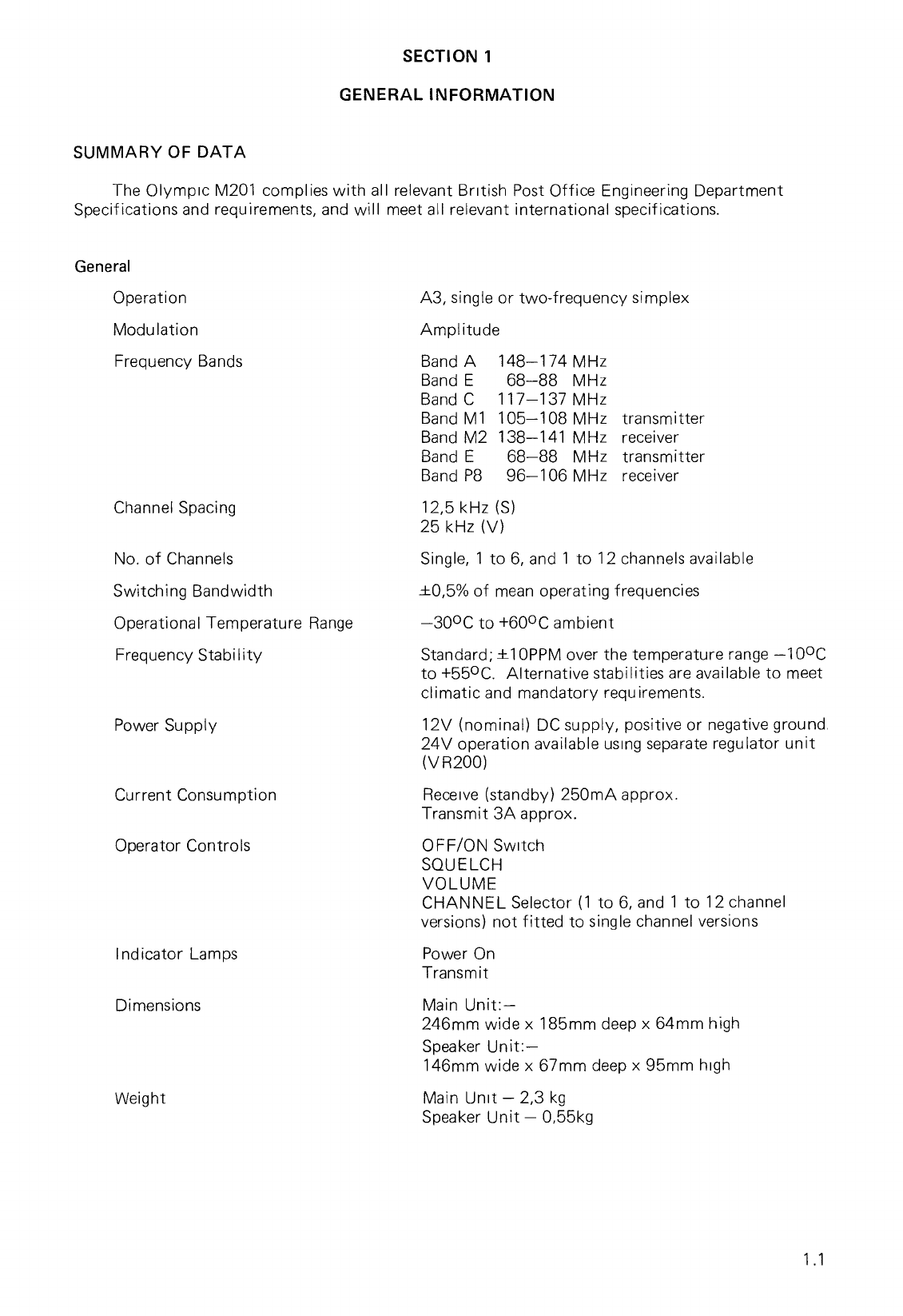

Optional Extras

1 to 6, and 1 to 12 channels

24V Regulator (VR200)

25W RF Power Amplifier (A200)

Loudspeaker/Microphone

Range of Selective Call Modules*

*Details available on application

50Q

1W for 0,5uV PD signal input, modulated 30% at

1 kHz

10 db at 0,611V PD signal input, modulated 30% at

1 kHz

2,5W with less than 10% distortion, modulated 30%

at 1 kHz

Receiver

Input Impedance

Sensitivity

Signal/Noise Ratio

Audio Output

Spurious Response Attenuation

At least 85 db (Image at least 70 db)

Squelch

Electronic, fully noise compensated.

Threshold sensitivity equal to or less than 0,4uV PD

with full 6 db range of adjustment above threshold

level.

Automatic Gain Control

The output does not increase by more than 6 db when

the input is increased from 0,511V to 0,5V PD.

Transmitter

Output Impedance

Power Output

Spurious Outputs

Modulation Response

50P

6W min, A, C and M Bands

8W min, E, Band at 13,8V DC input

(25W with separate power amplifier A200)

Each less than 2,51.W at antenna socket

Typically +1 to —3 db between 300 Hz and 2,5 kHz

relative to 1 kHz.

Typical figures based on normal operating conditions. Pye policy is one of continuous

improvement, therefore the right is reserved to change specifications without notice.

1.2