Summary of data (Contd.)

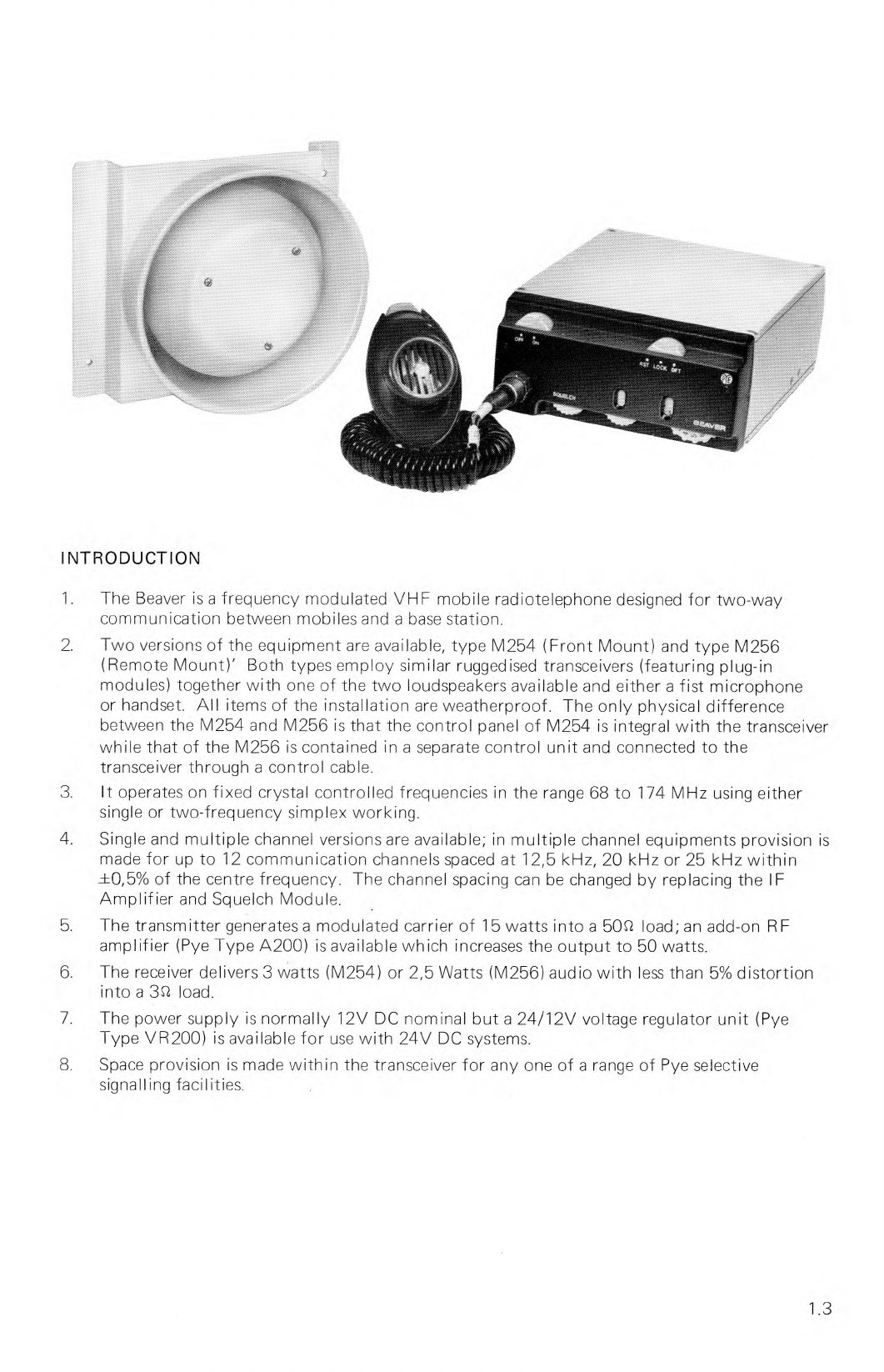

Finish

Optional Extras

Receiver

Input Impedance

Sensitivity

Signal/Noise

Audio Output

Audio Response

I ntermodulation Attenuation

Spurious Response Attehuation

Squelch

Main Unit

die cast aluminium finished in yellow

and Control Unit: with black polycarbonate front

panel

Speaker Unit.

Yellow

(i)

2-12 channels

(ii)

24V regulator — VR 200

(iii)

RF power amplifier — A200 (12V DC supplies only)

(iv)

Choice of antennas

(v)

Selection of Selective Call modules (Details on

application)

(vi)

Choice of frequency stabilities

(vii)

Telephone handset in place of fist microphone

(viii)

Adjustable Transmitter Power Module

(ix)

Choice of either circular bulkhead or re-entrant

horn loudspeaker (both weatherproof)

5052

20 db quieting for 0,35W PD signal input

12 db SINAD for 0,250V PD signal input

M254 3,0W with less than 5% distortion at 1 kHz

M256 2,5W with less than 5% distortion at 1 kHz

+1 db to —3 db of a 6 db per octave de-emphasis

characteristic from 300 Hz to 3 kHz

70 db

85 db

6 db quieting at threshold. Sensitivity adjustable

Transmitter

Output Impedance

50Ct

Power Output

15W minimum (at 13,8V DC input)

(Adjustable down to 5W as required 25-50W available

with separate power amplifier

Spurious Outputs

Harmonics 2,5 oW at antenna socket. Other outputs

0,25 oW at antenna socket.

Modulation

+1 db to —3 db of 6 db per octave pre-emphasis

characteristic from 300 Hz to 3 kHz

Modulation Distortion

Less than 5% at 1 kHz with 60% deviation

Typical figures based on normal operating conditions. Pye policy is one of continuous improvement

therefore the right is reserved to change specifications without notice.

1.2