10

SprayMaster® System User Manual | www.PyranhaInc.com | Houston, Texas

7. Remove the lid from the top of the drum and fill the drum about halfway with clean

water. Do NOT put insecticide in the drum until testing is completed. Replace the lid

on top of the drum. Do not restrict the float line and tubing.

8. Connect the electrical cord from the timer to an 110V outlet. Open the bleed valve

and hold inside the drum. Open the timer cover and start the system by flipping the

toggle switch to “TEST.” Allow the system to operate for several minutes to be certain

the pump is priming and there are no leaks at the various tubing connections. Once a

steady stream is flowing into the drum, close the bleed valve.

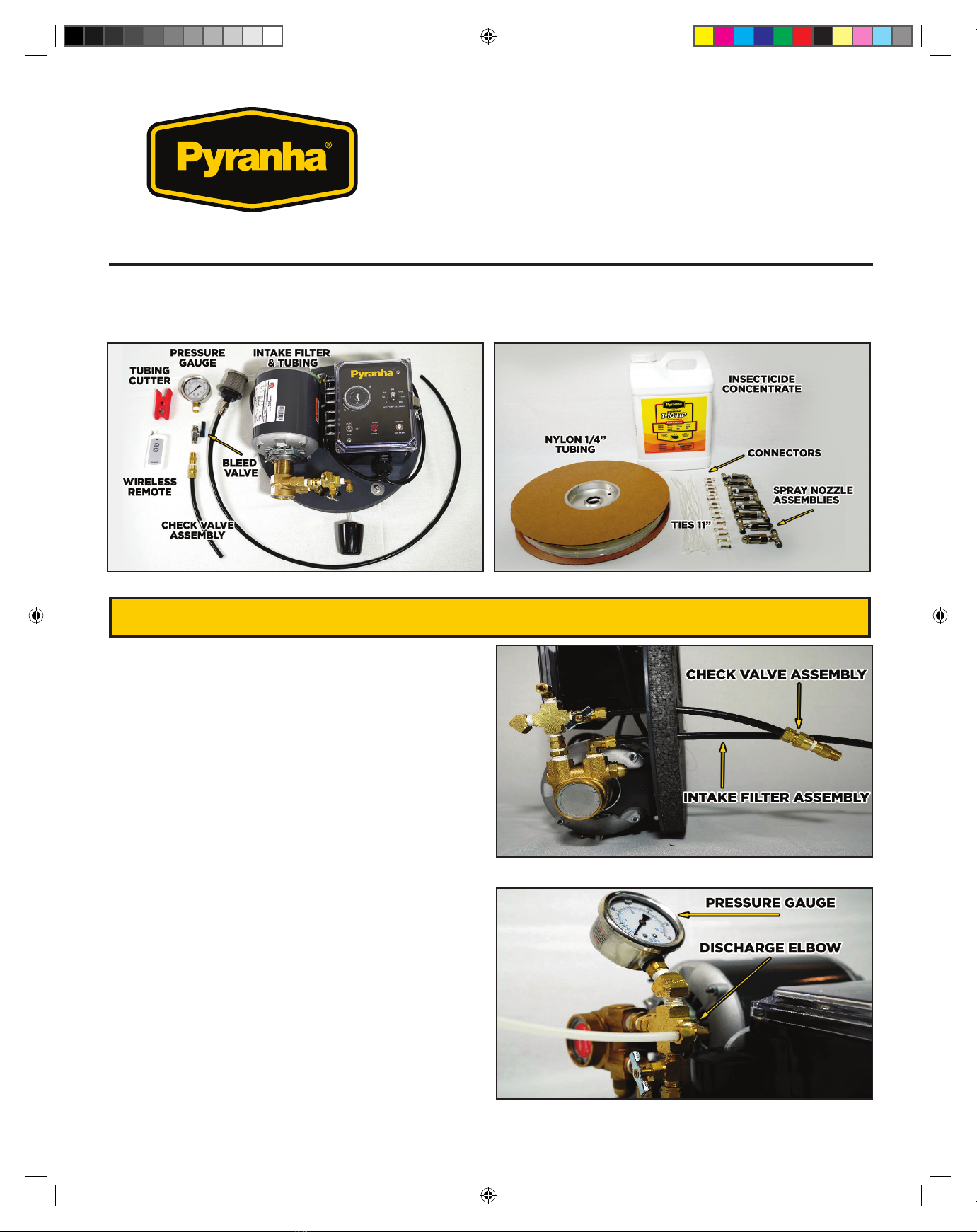

9. Turn the pressure regulating valve clockwise until the pressure gauge reads between

190psi and 210psi (Figure 7), and all nozzles are spraying a consistently fine mist.

Check again for leaks at the tubing connections.

10. After confirming the spray nozzles are operating correctly with no leads at the tubing

connections, flip the toggle switch to “OFF” and disconnect the electrical cord from

the outlet. Close the timer lid.

11. Carefully lift the drum lid and shift it to the side of the drum top. Add the entire

contents of the insecticide concentrate to the drum and finish filling with clean water

to four (4) inches from the top of the drum. Replace the lid on the drum (being

careful not to pinch the float line or kink the tubing) and reconnect the electrical

cord. Secure the lid in place with the metal ring. The latch on the metal ring can be

locked in place for security to keep the drum from being opened.

12. Open the timer cover. Open the bleed valve and hold in the drum. Flip the toggle

switch to “TEST” to fill the nozzle line with insecticide. Close the bleed valve once

insecticide is flowing through it. Adjust the pressure between 190psi and 210psi, if

necessary.

NOTE: The system works best between

190psi-210psi and must not be set

below 185psi, or over 215psi.

DO NOT OPERATE SYSTEM WITH THE

PRESSURE REGULATING VALVE

CLOSED.

FIGURE 7

System_Manual_2020.indd 10System_Manual_2020.indd 10 12/23/20 10:18 AM12/23/20 10:18 AM