Pyxis SP-710B Multimeter Operation Manual 3

Table of Contents

1Introducing the Pyxis SP-710B Multimeter...................................................................................5

1.1 Features of the Pyxis SP-710B.......................................................................................................5

1.2 Specifications ................................................................................................................................6

1.3 Unpacking the Pyxis SP-710B........................................................................................................6

1.4 Standard Accessories ....................................................................................................................6

1.5 Optional Accessories.....................................................................................................................7

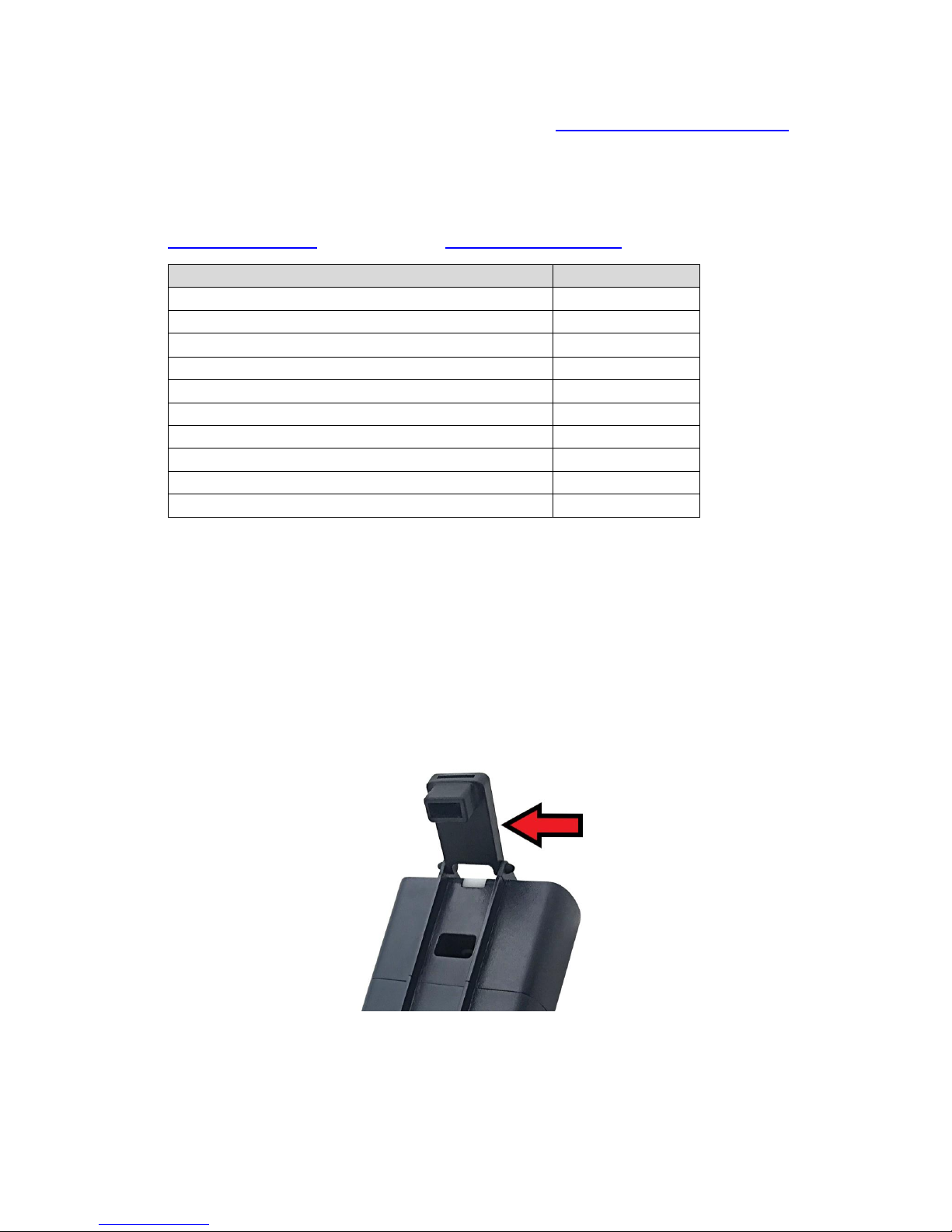

1.6 Dual Function Seal for the pH/ORP Cell........................................................................................7

2Using the Pyxis SP-710B..............................................................................................................8

2.1 Battery Installation........................................................................................................................8

2.2 Turning the SP-710B ON and OFF .................................................................................................9

2.3 Turn on the pH/ORP Module Power.............................................................................................9

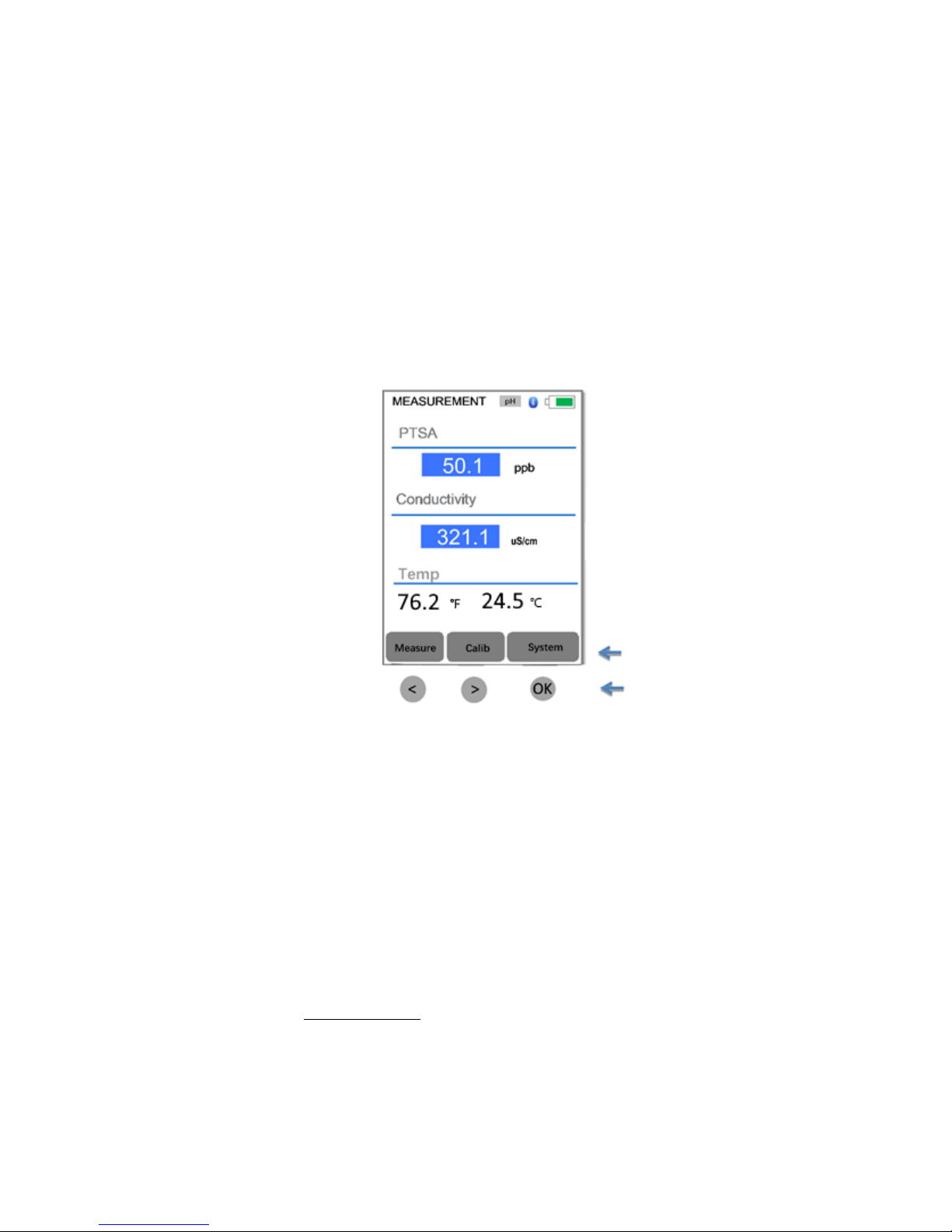

2.4 Using the SP-710B Control Keys..................................................................................................10

3Multiple Parameter Measurement............................................................................................10

3.1 PTSA and Conductivity Measurement ........................................................................................10

3.2 Fluorescein Measurement..........................................................................................................11

3.3 pH and ORP Measurement .........................................................................................................11

3.4 Temperature Measurement .......................................................................................................13

3.5 Conductivity Temperature Compensation..................................................................................13

3.6 High Color and Turbidity Warning ..............................................................................................13

3.7 pH Measurement Principle.........................................................................................................13

3.8 ORP Measurement Principle.......................................................................................................14

4Calibrating the SP-710B.............................................................................................................14

4.1 PTSA Standalone Calibration (2 point with zero)........................................................................15

4.2 Combined Calibration Procedure................................................................................................15

4.3 Standard Conductivity Calibration (500, 1000, 2500, or 5000 µS) .............................................17

4.4 User-Defined Conductivity Calibration Procedure......................................................................18

5pH and ORP Calibrations...........................................................................................................19

5.1 pH Electrode Calibration.............................................................................................................19

5.1.1 One-Point Calibration .........................................................................................................20

5.1.2 Second-Point Calibration ....................................................................................................20

5.1.3 Third-Point Calibration........................................................................................................20

5.2 ORP Calibration...........................................................................................................................21

6Fluorescein Calibration .............................................................................................................22

7Device Information and Diagnosis.............................................................................................24

8Device Maintenance.................................................................................................................25

9Replacing the pH/ORP module (Part #50313).............................................................................25

9.1 Module Replacement..................................................................................................................25

9.2 Bluetooth Pairing Your pH/ORP Module to SP-710B..................................................................27

10 Bluetooth Connection of SP-710B to Devices.............................................................................27