PAGE 2

AB

CD

FIG. 1

*

*

*

*

View Setpoint in oC / oF units

(PRESS)

Increase Setpoint

Decrease Setpoint

(3 sec.) Enter/Exit Menu Levels

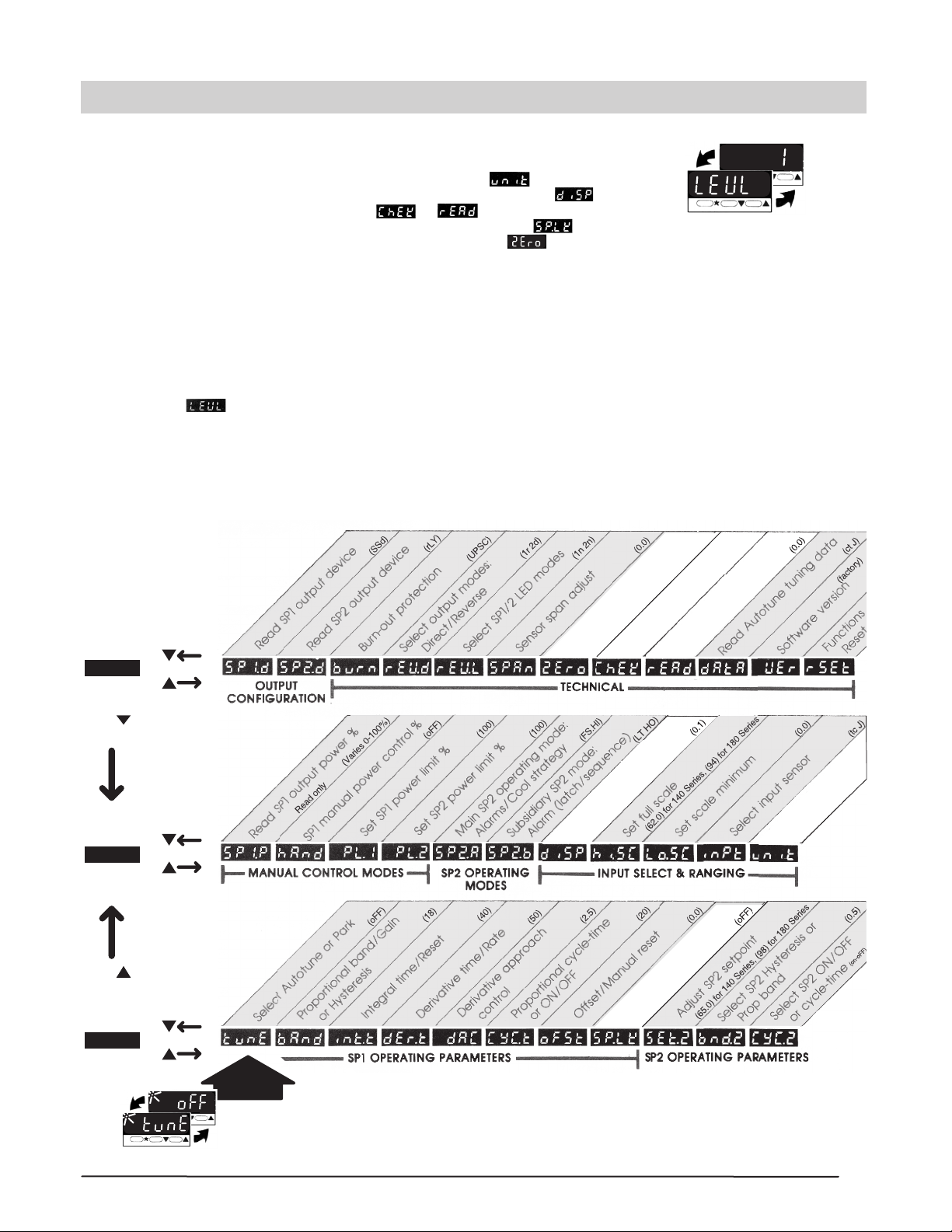

FIG. 2

Set-up & Installation

Read Operating Instructions Thoroughly Prior to Operation

Safety Precautions

Read Operating Instructions thoroughly prior to operation. Use only a grounded outlet that is rated for your

model's electrical requirement. Do not modify the oven or factory control settings to operate the oven above the

stated maximum operating temperature. Exterior surfaces on 180E-1 models may become hot to the touch when

operating at higher set temperatures. Conduct periodic maintenance as required.

General Operation

*

Chamber Loading

Position unit in its ultimate operating location. Keep a minimum of

3" of airspace around the unit and a minimum of 6" above the unit.

The port hole at the top of the unit will expel a small amount of

warm air through natural convection. This port can also be used as

an access way for external temperature measurement of a solution

for example.

Install adjustable shelf by placing the ends of the wire shelf bracket

into the corresponding holes located on the inner sides of the oven

at the desired height. Push the ends of the bracket into the holes

until the first bends in the bracket are against the wall, then rotate

the bracket down. Place the shelf on the brackets. (FIG 1)

Plug the unit into a grounded outlet for your unit's rated voltage.

The unit is ready for your immediate use. All control parameters,

calibration and tuning has been done at the factory, no adjustments

are necessary.

Push the illuminated power button. All LED's on the temperature

control will light up for 5 seconds until the current or actual chamber

temperature is displayed.

To view the set temperature press the star " " key. To change the

set temperature, hold the star key together with the up (raise temp)

or down (lower temp) arrow key until the desired temperature is

indicated on the LED display. (FIG 2) The temperature control is

set at the factory to read in 1/10 degree C (centigrade) units. To

change temperature units or display resolution see: Menu Level

Functions (page 3).

Once the unit reaches the set temperature, allow the unit to cycle

for 20 minutes at set point before temperature becomes fully stable.

NOTE: Upon each initial powering-up, the control may typically overshoot the set temp by 2 to 4 degrees,

especially if the temperature set point is close to the operating ambient temperature. After equilibrium is achieved

the control will hold set temperature within 1 unit degree.

Article processing times and temperature uniformity are largely dependent on load density and positioning. Load

the incubator so that the air circulation within the incubator is not impaired. Here are some general guidelines:

Leave a space between articles on a shelf. Stagger articles from those on lower shelves.

Avoid placing articles or media against or within an inch of the walls, especially on the lower shelf. Heated air from

the lower plenum openings, designed to travel up the side walls, can have a slightly elevated temperature from set

point and the rest of the chamber.

Use of large solid trays or foil on shelves limits heat to any articles placed on shelves above.

Avoid extremely large (in quantity or size), or high-density loads. This will show by non-uniform processing and

long or impossible "heat-through" times. To help determine a load's suitability, use the set-point recovery time (the

time it takes for the temperature to recover to the original set temperature once the load is placed), as a guide. To

reduce recovery time, reduce load proportionally. When possible, measure large loads or solution temperatures

directly with an ancillary thermometer or probe. Probes can be inserted at the top port.

For best processing performance for a single item, adjust one shelf so that the article is centered in the incubator

chamber.