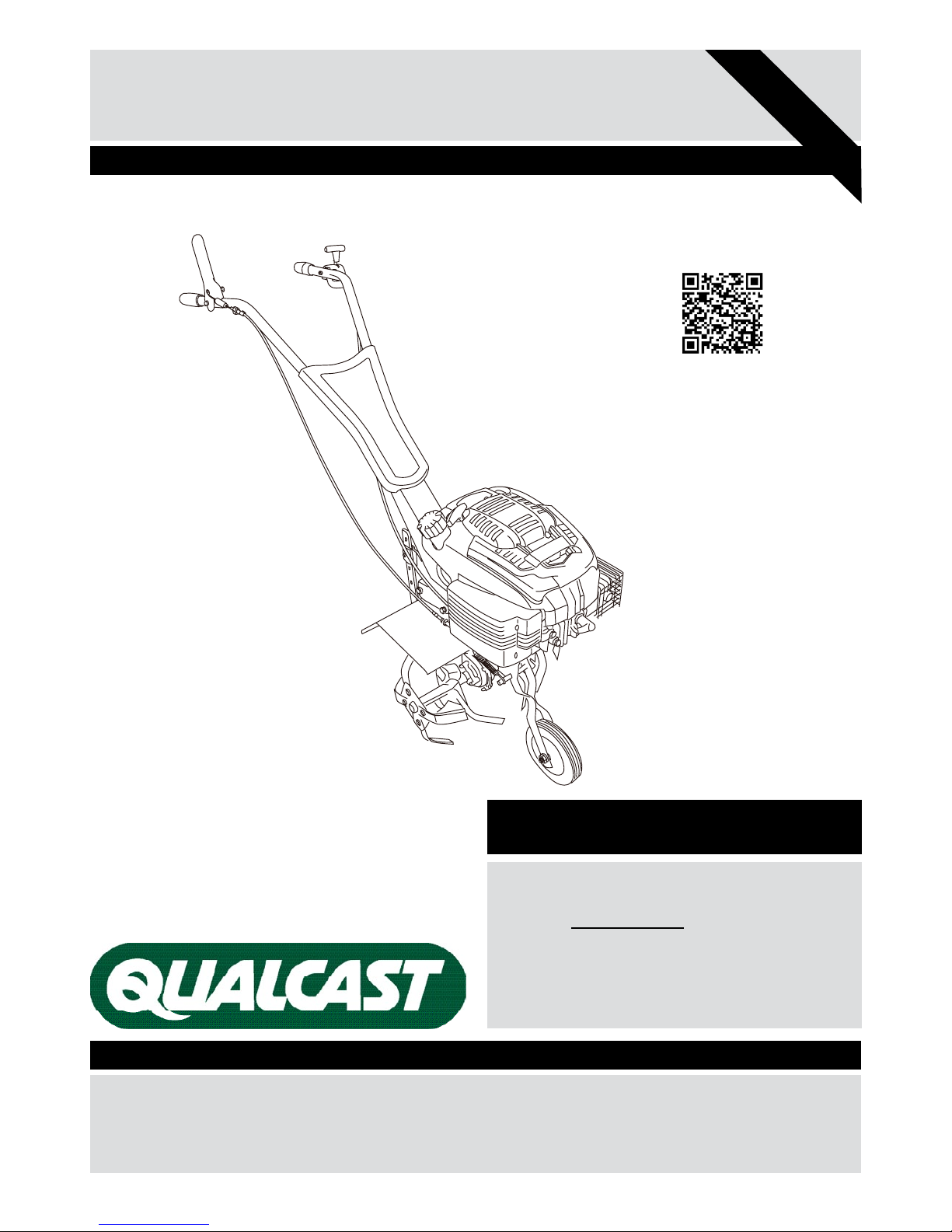

Important - Please read these instructions fully before operating or maintaining

4

Important - Please read these instructions fully before operating or maintaining

5

Customer Helpline 0845 034 2279

www.gardenservicecentre.co.uk

Customer Helpline 0845 034 2279

www.gardenservicecentre.co.uk

WARNING! Keep this operating and maintenance manual in a safe place for reference at a later

date.

WARNING! Read the instructions carefully. Be familiar with the controls and the proper use of the

equipment.

WARNING! Never allow children or people unfamiliar with these instructions to use the rotavator.

Local regulations can restrict the age of the operator.

WARNING! Never mow while people, especially children, or pets are nearby. Keep in mind that the

operator or user is responsible for accidents or hazards occurring to other people or their property.

WARNING! This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have

been given supervision or instruction concerning use of the appliance by a person responsible for

their safety.

WARNING! Do not touch rotating blade.

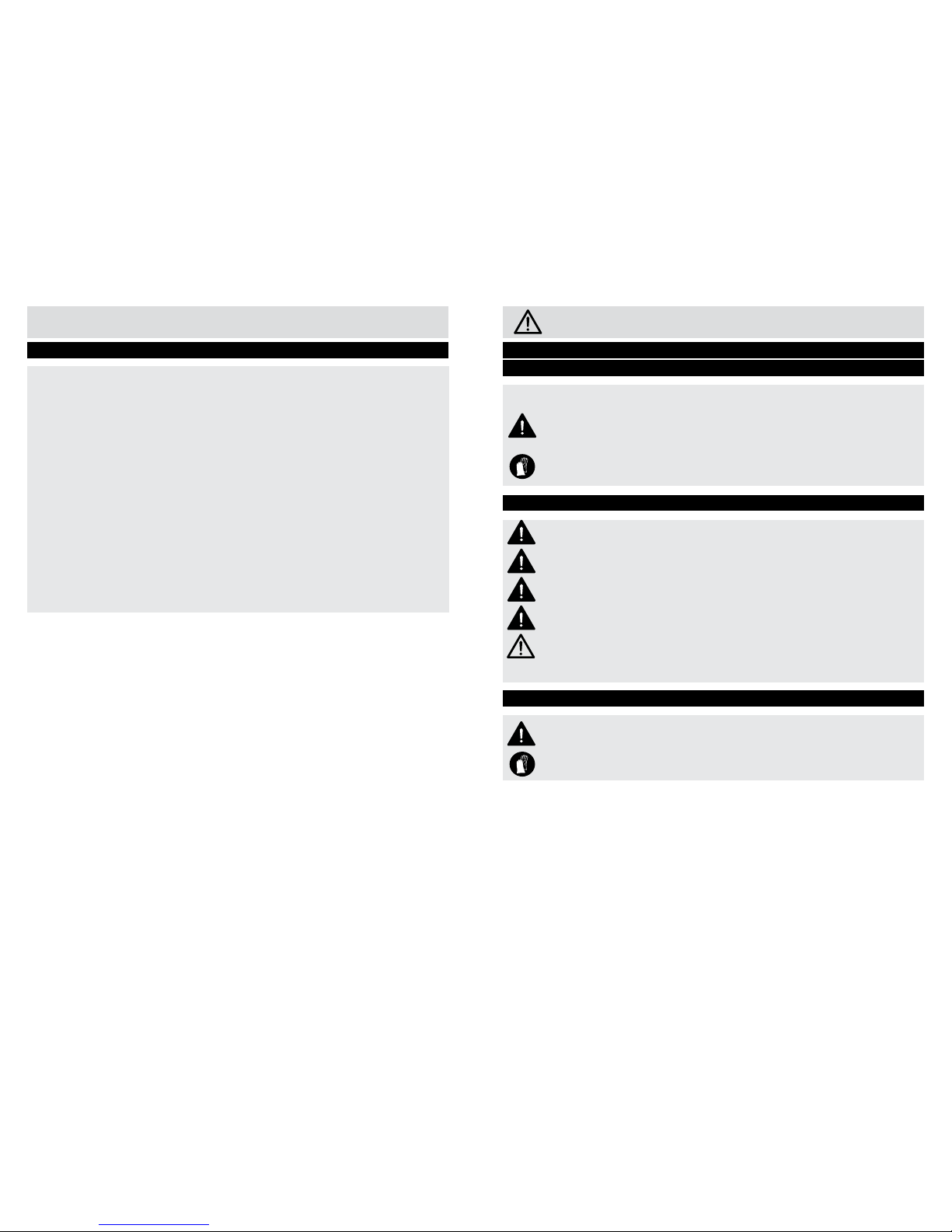

General Safety

Safety Information

a). Do not operate the engine in a conned space where dangerous carbon monoxide fumes can

collect.

b). Work only in daylight or in good articial light.

c). Always be sure of your footing in slopes.

d). Walk, never run with the machine.

e). For wheeled rotary machines, work across the sloped, never up and down.

f). Exercise extreme caution when changing direction on slopes.

g). Do not work on excessively steep slopes.

h). Use extreme caution when reserving or pulling the machine towards you.

i). Do not change the engine governor setting or over speed the engine.

j). Start the engine carefully according to manufacturer’s instructions and with feet well away from the

tools.

k). Do not put hands or feet near or under rotating parts.

l). Never pick up or carry a machine while the engine is running

m). Stop the engine:

- whenever you leave the machine

- before refueling

n) Reduce the throttle setting during engine shut down and, if the engine is provided with a shut-off

valve, turn the fuel off at the conclusion of working.

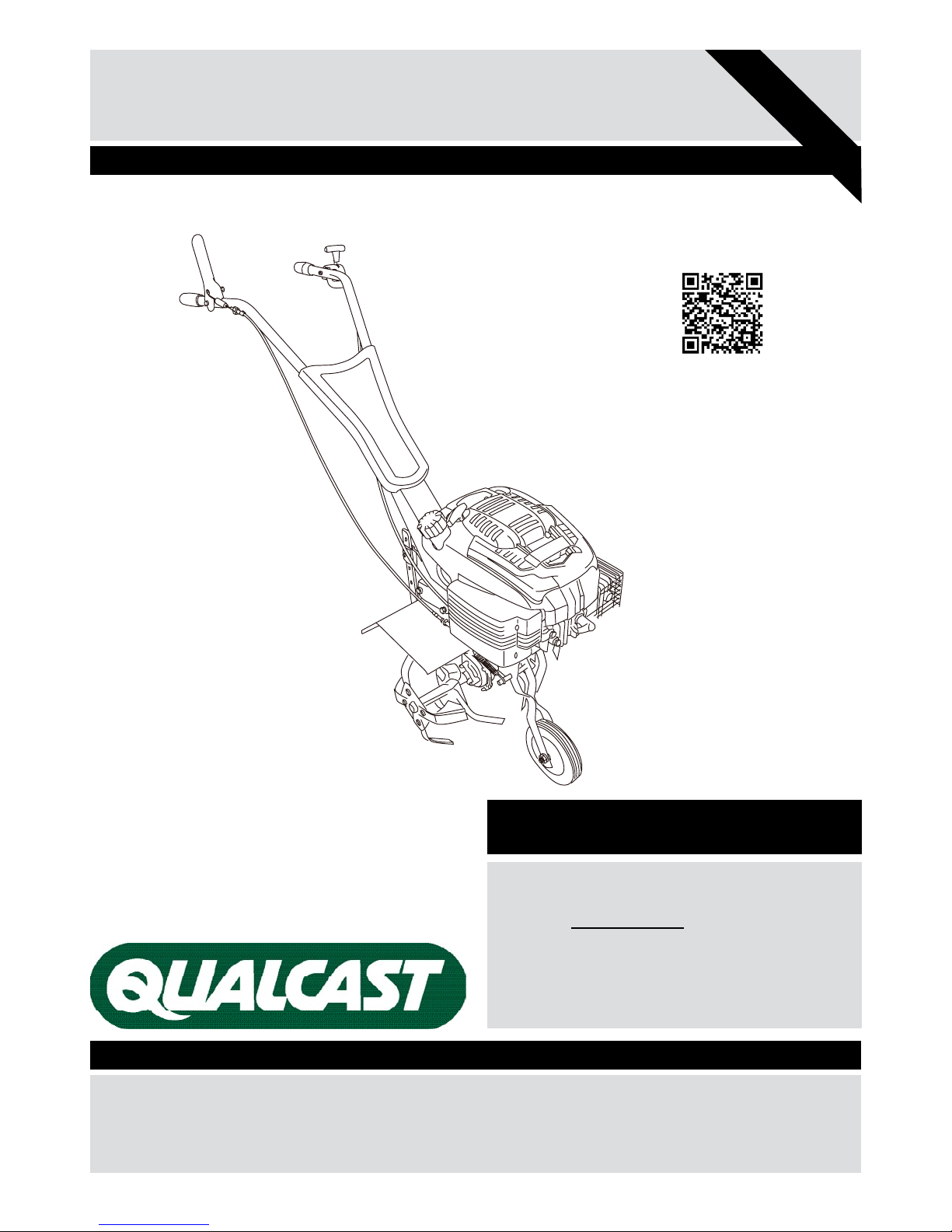

Preparation (continued)

Safety Information

Preparation

a). While working, always wear substantial footwear and long trousers. Do not operate the

equipment when barefoot or wearing open sandals.

b). Thoroughly inspect the area where the equipment is to be used and removed all objects which

can be thrown by the machine.

c). WARNING! Petrol is highly ammable:

- store fuel in containers specically designed for this purpose;

- refuel outdoors only and do not smoke while refueling;

- add fuel before starting the engine. Never remove the cap of fuel tank or add petrol while the

engine is running or when the engine is hot;

- if petrol is spilled, do not attempt to start the engine but move the machine away from the area of

spillage and avoid creating any source of ignition until petrol vapours have dissipated;

Training

a). Read the instruction carefully. Be familiar with the controls and proper use of the equipment.

b). Never allow children or people unfamiliar with these instructions to use the machine. Local

regulations can restrict the age of the operator.

c). Never work while people, especially children, or pets are nearby.

d). keep in mind that the operator or user is responsible for accidents or hazards occurring to other

people or their property.

- replace all fuel tank and container caps securely.

d). Replace faulty silencers;

e). Before using, always visually inspect to see that the tools are not worn or damaged. Replace

worn or damaged elements and bolts in sets to preserve balance.

Operation