Submersible Sewage and Effluent Pumps

INSTALLATION AND OPERATION MANUAL

SAFETY INFORMATION

Carefully read and follow all safety instructions in this

manual or on pump.

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for one of the

following signal words and be alert to the potential for

personal injury!

warns about hazards that will cause serious

personal injury, death or major property damage if ignored.

warns about hazards that can cause serious

personal injury, death or major property damage if ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The word NOTICE indicates special instructions which are

important but not related to hazards.

1. Read these rules and instructions carefully. Failure to

follow them could cause serious bodily injury and/or

property damage.

2. Check your local codes before installing.You must comply

with their rules.

3. Vent sewage or septic tank according to local codes.

4. Do not install pump in any location classified as hazardous

by National Electrical Code, ANSI/NFPA 80-1984 or the

Canadian Electrical Code.

Hazardous voltage. Can shock, burn,

or cause death. During operation the pump is in water.

To avoid fatal shocks, proceed as follows if pump needs

servicing:

5A. Disconnect power to outlet box before unplugging pump.

5B. Take extreme care when changing fuses. Do not stand

in water or put your finger in fuse socket.

5C. Do not modify cord and plug. When using cord and plug,

plug into a grounded outlet only. When wiring to a system

control, connect pump ground lead to system ground.

6. Do not run pump dry. Dry running can overheat pump,

(causing burns to anyone handling it) and will void

warranty.

7. Pump normally runs hot. To avoid burns, allow it to cool

for 20 minutes after shut-down before handling it.

8. Pump is permanently lubricated. No oiling or greasing is

required in normal operation.

INSTALLATION

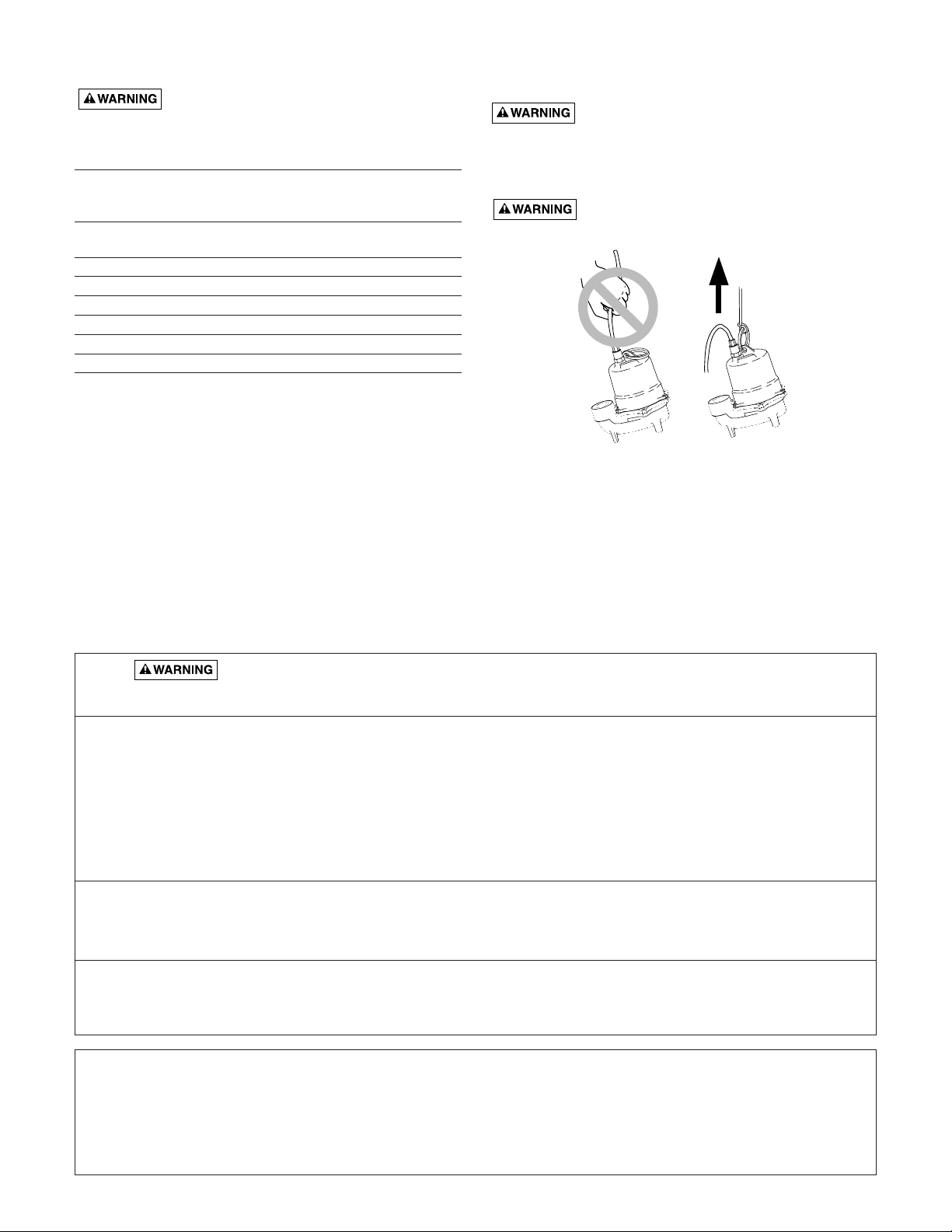

Risk of electrical shock. Can burn or kill.

Do not lift pump by power cord. See “Cord Lift Warning” on

next page.

NOTICE: Install pump on a hard, level surface (cement,

asphalt, etc.). Never place pump directly on earth, clay or

gravel surfaces.

Piping

Piping must not be smaller than pump discharge.

When installed in an effluent system, pipe must be capable

of handling semi-solids of at least 3/4" diameter.

The rate of flow in the discharge pipe must keep any solids

present in suspension in the fluid. To meet minimum flow

requirements (2 feet per second in discharge line), size pipe

as follows:

A Pipe Size Of: Will Handle a Flow Rate Of:

1-1/2" 12 GPM

2" 21 GPM

2-1/2" 30 GPM

3" 48 GPM

In an effluent system use a 1-1/2" check valve in pump dis-

charge to prevent backflow of liquid into sump basin. The check

valve should be a free flow valve that will easily pass solids. Be

sure check valve installation complies with local codes.

NOTICE: For best performance of check valve when han-

dling solids, do not install it with discharge more than 45°

above the horizontal. Do not install check valve in a vertical

position as solids may settle in valve and prevent opening

on startup.

Drill a 3/16" hole in discharge pipe about 1– 2" above pump

discharge connection (but below check valve) to prevent air-

locking the pump. Models P-SU-13T and P-SE-13T have

built-in anti-airlock hole in the pump body; drilling is not nec-

essary on these models.

Electrical

Hazardous voltage. Can shock, burn, or

cause death. When installing, operating, or servicing this

pump, follow safety instructions listed below.

1. DO NOT splice the electrical power cord.

2. DO NOT allow electrical cord plug to be submerged.

3. DO NOT use extension cords. They are a fire hazard

and can reduce voltage sufficiently to prevent pumping

and/or damage motor.

4. DO NOT handle or service pump while it is connected to

power supply.

5. DO NOT remove grounding prong from plug or modify

plug on cord-connected models. To protect against elec-

trical shock, the power cord is a three-wire conductor

and includes a 3-prong grounded plug. Plug pump into

an individual branch circuit with a 3-wire, grounded,

grounding-type receptacle. Connect pump according to

the NEC or CEC and local codes.

For automatic operation, plug or wire pump into an automat-

ic float switch or duplex controller. Pump will run continuous-

ly when plugged directly into an electrical outlet.

© 2006 Q527 (5/23/06)

MODELS

1/3 HP P-SE-13T P-SU-13T

4/10 HP P-SE-41T P-SS-41T

1/2 HP P-SE-12T P-SS-12T

3/4 HP P-SS-34T

1 HP P-SE-10T