1. Safety instructions

1.1 Installation and commissioning

Place the unit on a plain, dry and clean place. Pay attentionthat the connectingcable is

untangled and free and that nothing is resting on it. For direct product cooling use the

cooling coil offered by the manufacturer only (optional item). It is imperative to provide

sufficient ventilation of the unit. The ventilation slots must remain free for sufficient

evacuation of heat. No objects may be placed under the unit!

The following safety measures must be observed:

Min. water temperature: -6 °C(with propylene glycol)

Max. water temperature: +30 °C

Max. ambient temperature: +32 °C

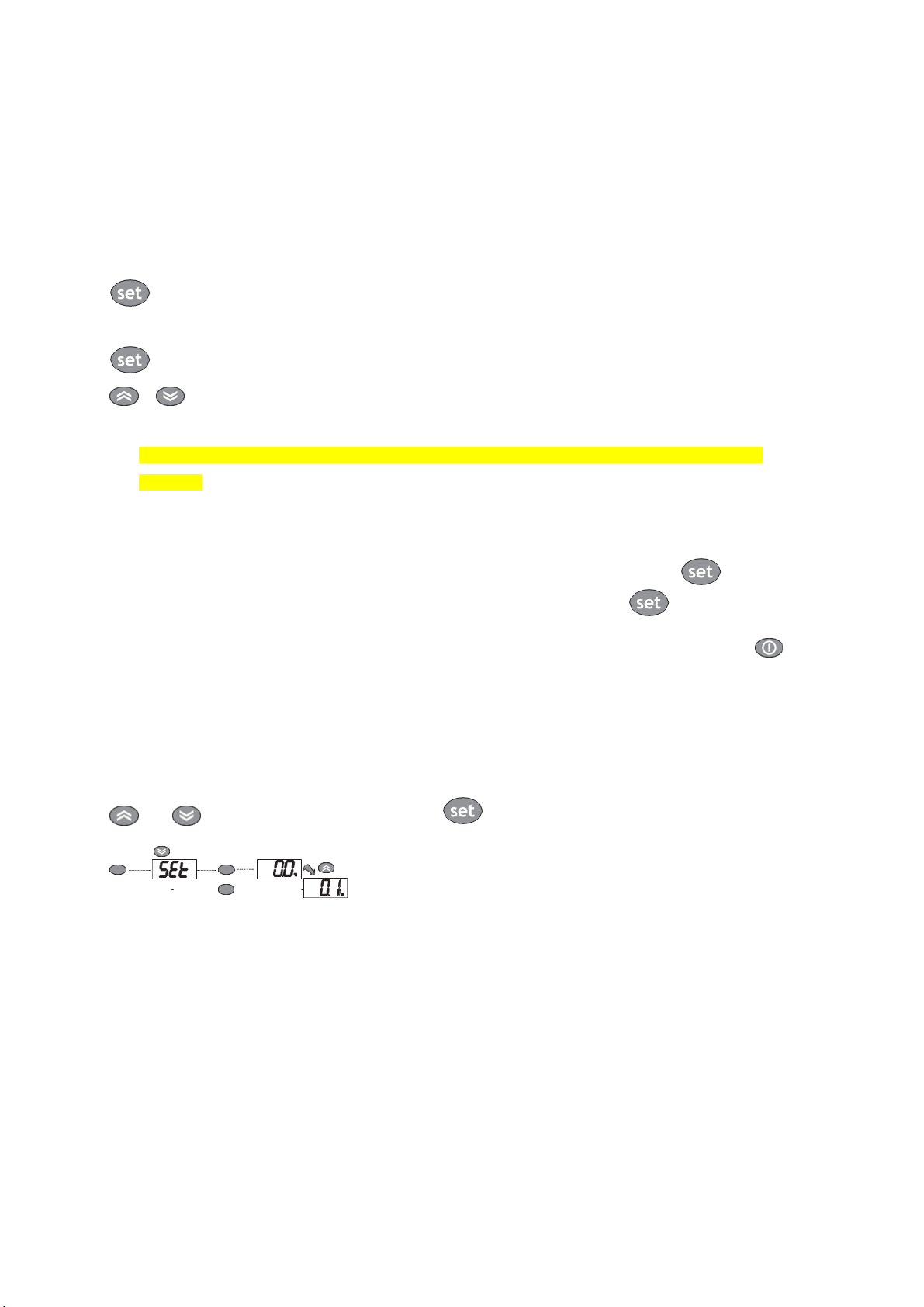

ATTENTION: For cold watertemperatures below 0 °C it is mandatory, to add

30 % of propylene glycol to the coolingwater!

Note:There can be noice bankbuilding whenusingGlycol.

Keep the unit clean fromany dirt, fiber etc.

Make sure to connect the unit to the required supplyvoltage

Protect the unit frommoisture, no fluids may enter the electric parts

Observe the warning and safety information on the electrical components and in

this instruction manual

1.2 Safetyinformation

The unit should be connectedand operatedby trainedpersonnel. Adjustments,

maintenance and repairs should be performedby qualified personnel.

Correct function and reliability of operationsof this unit can only be warranted, if during

operation and servicethe general common saftey precautions, as wellas the specific

safety instructions describedin this manual will be carefully observed.

Handling and treatment of the unit not according to the safety instructions required for

electrical appliances and the instruction in this document may result in severe bodily

harmwhich is not under the responsibility of the manufacturer. Injury and property

damage can accure through:

inappropriateoperation

incorrect installation or operation

improper removal of the necessary protective cover or housing,wetting the electrical

parts

Opening of the unit during operation, which isprohibited

1.2.1 Impairment ofsafety

If the unit is damaged, it must be unplugged, set aside, marked to warn others against

using it, and a technician must be called beforeit is returnedto operation. Using the unit

if itis damaged is unsafe and therefore stricktly prohibited.