ENGLISH

2 - Edition 10/2014 Cod. 2200780113 01 -

CHARACTERISTICS AND SAFETY PRECAUTIONS

BEFORE REMOVING THE PROTECTIVE GUARDS TO CARRY OUT ANY MAINTENANCE ON THE MACHINE, SWITCH OFF THE ELECTRIC

POWER SUPPLY AND DISCHARGE THE RESIDUAL PRESSURE INSIDE THE UNIT.

ALL WORK ON THE ELECTRIC PLANT, HOWEVER SLIGHT, MUST BE CARRIED OUT BY PROFESSIONALLY SKILLED PERSONNEL.

The manufacturer does not accept responsibility for damage caused as a result of negligence of failure to abide by the instructions given

above.

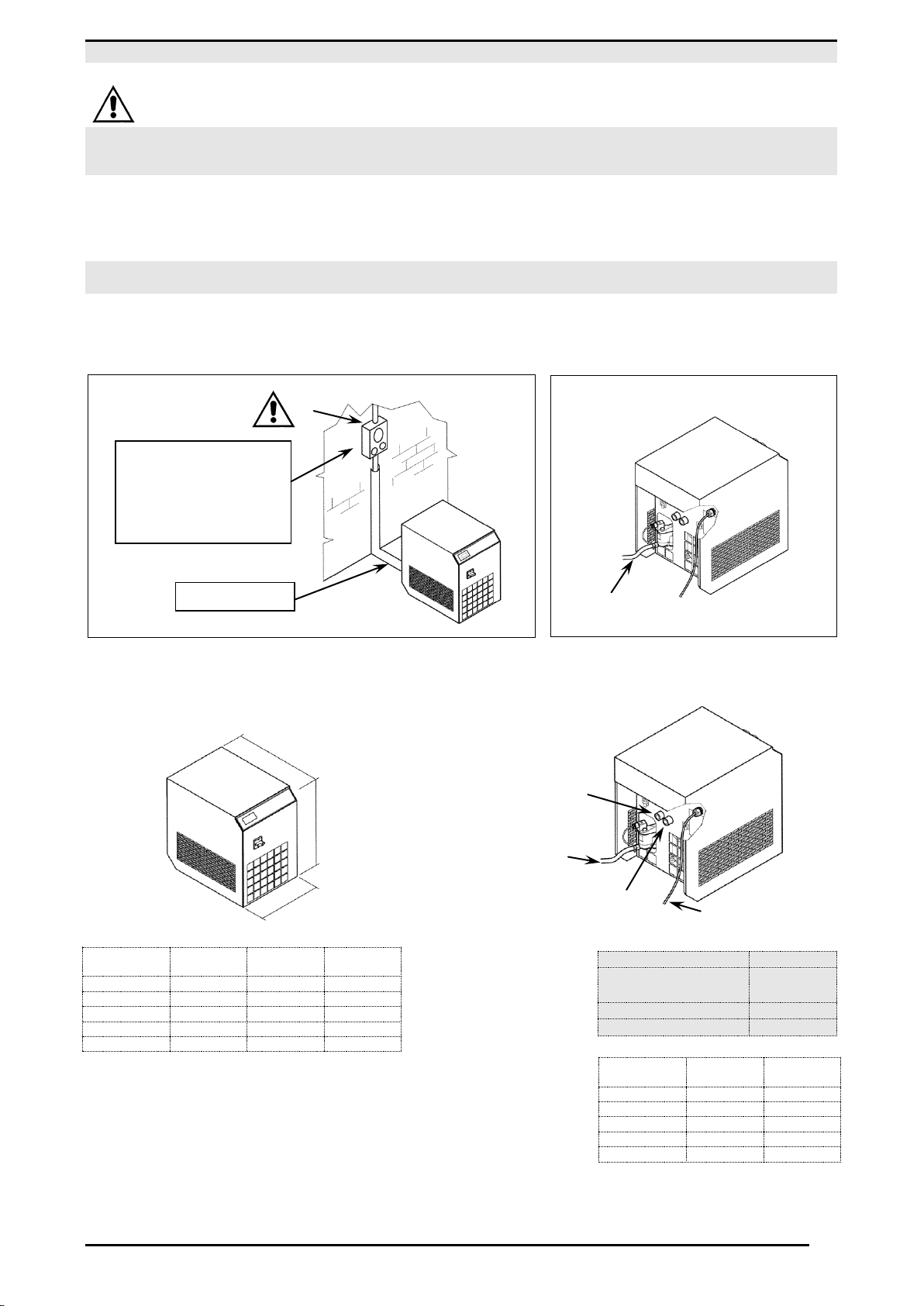

THIS MACHINE IS NOT SUITABLE FOR EXTERNAL INSTALLATION

THIS MACHINE CORRESPOND TO THE ESSENTIAL SAFETY REQUIREMENTS FORESEEN FROM THE EUROPEAN

STANDARD 2006/42.

THE LUBRICATING LIQUIDS AND OTHER EVENTUAL FLUIDS MUST NOT BE DISCHARGED IN THE ENVIRONMENT. THESE

POLLUTING AND HAZARDOUS PRODUCTS MUST COMPULSORY BE DISPOSED BY CHARGING AUTHORISED AND

SPECIALISED FIRMS ACCORDING TO THE DIFFERENT TYPOLOGY OF PRODUCT.

DIFFERENTIATE THE COMPRESSOR COMPONENTS ACCORDING TO THE DIFFERENT CONSTRUCTION MATERIALS (PLASTIC,

COPPER, IRON, OIL FILTER, AIR FILTER ECC…)

1.0 GENERAL CHARACTERISTICS

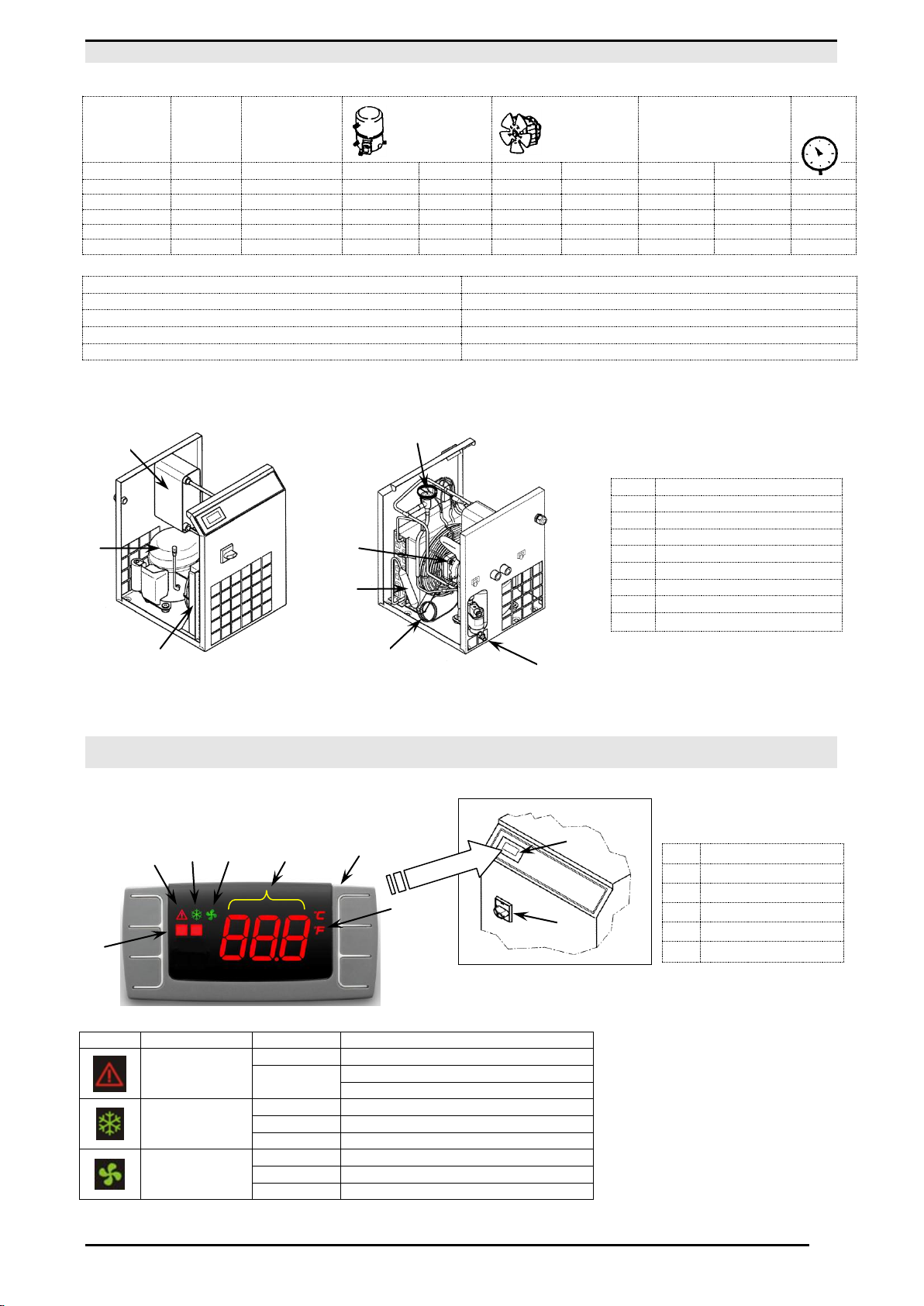

The dryer is a chilling machine with direct expansion and dry evaporator.

The air to be dried is sent to the heat exchanger in which the water vapour present is condensed: the condensate gathers in the separator

and is discharged outside through a steam trap.

2.0 INTENDED USE

The dryer has been built to dry the compressed air for industrial use. The dryer cannot be used in premises where there is a risk of fire or

explosion or where work is carried out which releases substances into the environment which are dangerous with regard to safety (for

example: solvents, inflammable vapours, alcohol, etc.).

In particular the appliance cannot be used to produce air to be breathed by humans or used on direct contact with foodstuffs. These uses

are allowed if the compressed air produced is filtered by means of a suitable filtering system

(Consult the manufacturer for these special uses.)

This appliance must be used only for the purpose for which it was specifically designed. All other uses are to be considered incorrect and

therefore unreasonable. The Manufacturer cannot be held responsible for any damage resulting from improper, incorrect or unreasonable

use.

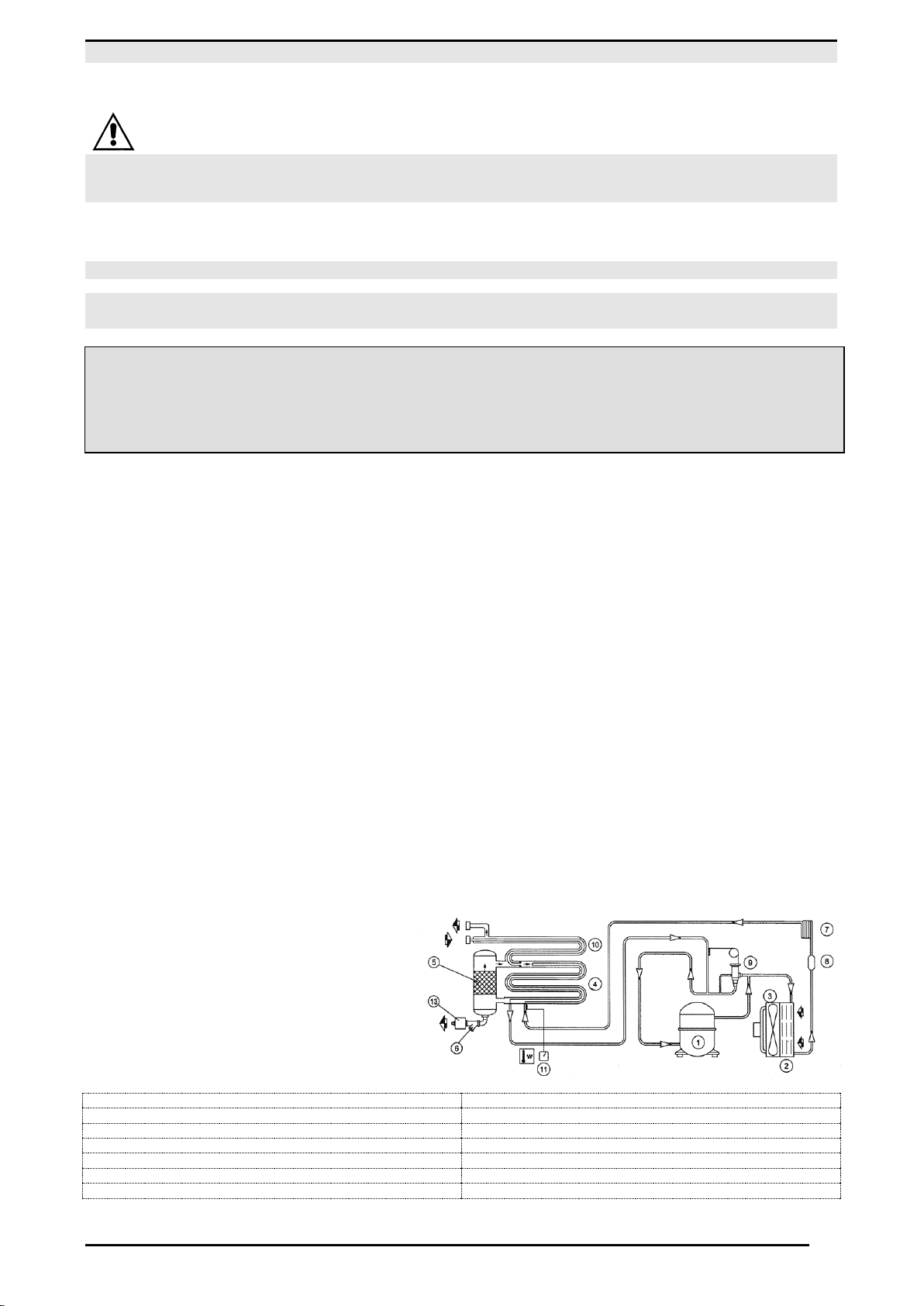

3.0 OPERATION

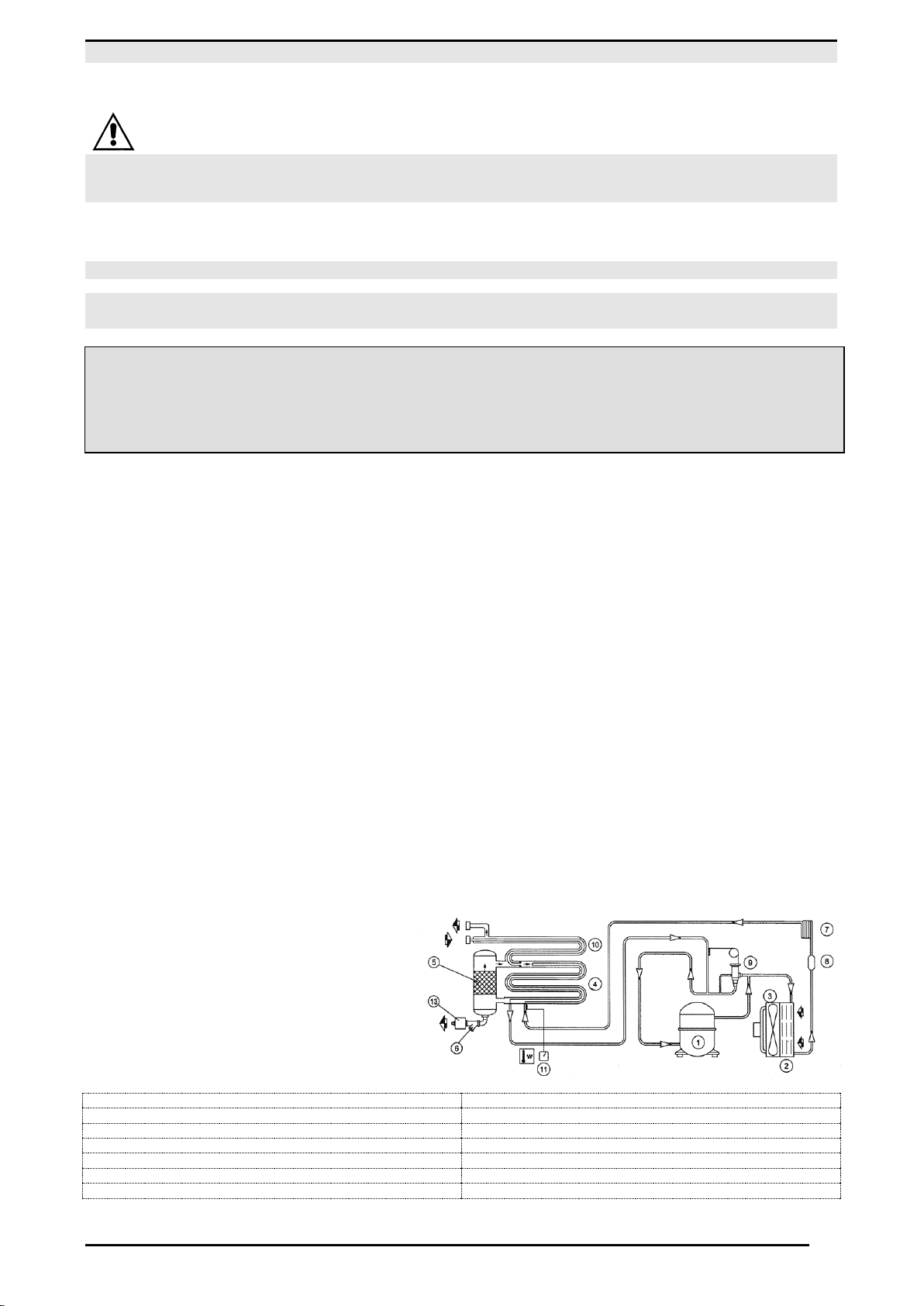

The gaseous refrigerant coming from the evaporator (4) is sucked by the refrigeration compressor (1) and it is pumped into the condenser

(2). This one allows its condensation, eventually with the help of the fan (3); the condensed refrigerant passes through the dewatering filter

(8) and it expands through the capillary tube (7) and goes back to the evaporator where it produces the refrigerating effect.Due to the heat

exchange with the compressed air which passes through the evaporator against the stream, the refrigerant evaporates and goes back to

the compressor for a new cycle.

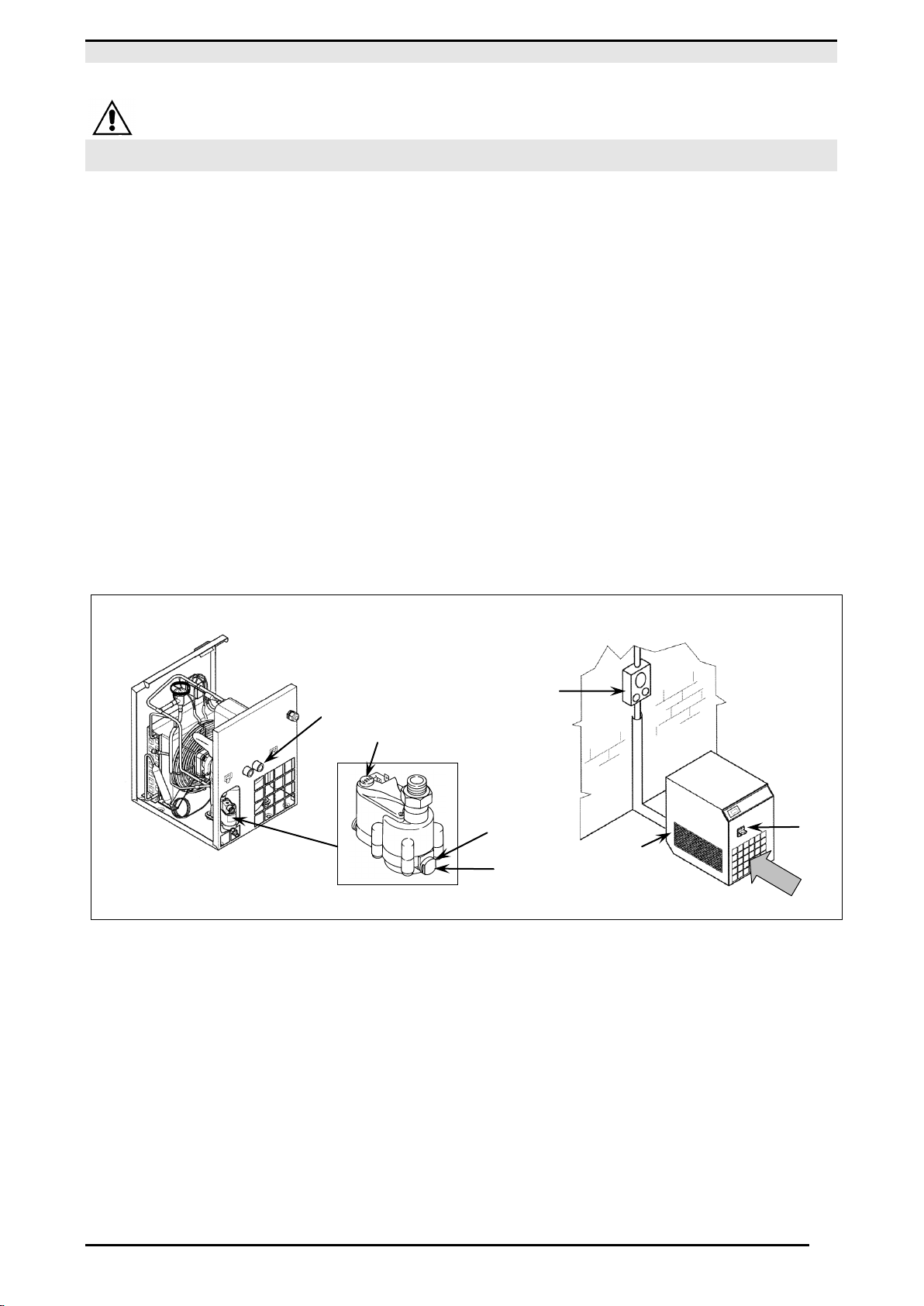

The circuit is equipped with a bypass system for the refrigerant; this intervenes to adjust the available refrigerating capacity to the actual

cooling load. This is achieved by injecting hot gas under the control of the valve (9): this valve keeps constant the pressure of the refrigerant

in the evaporator and therefore also the dew point never decreases below 32 °F (0 °C) in order to prevent the condensate from freezing

inside the evaporator. The drier runs completely automatically; it is calibrated in the factory for a dew point of 39 °F (4 °C) and therefore no

further calibrations are required.

DRYER FLOW DIAGRAM

1) REFRIGERANT COMPRESSOR

5) DEMISTER CONDENSATE SEPARATOR

7) EXPANSION CAPILLARY TUBE