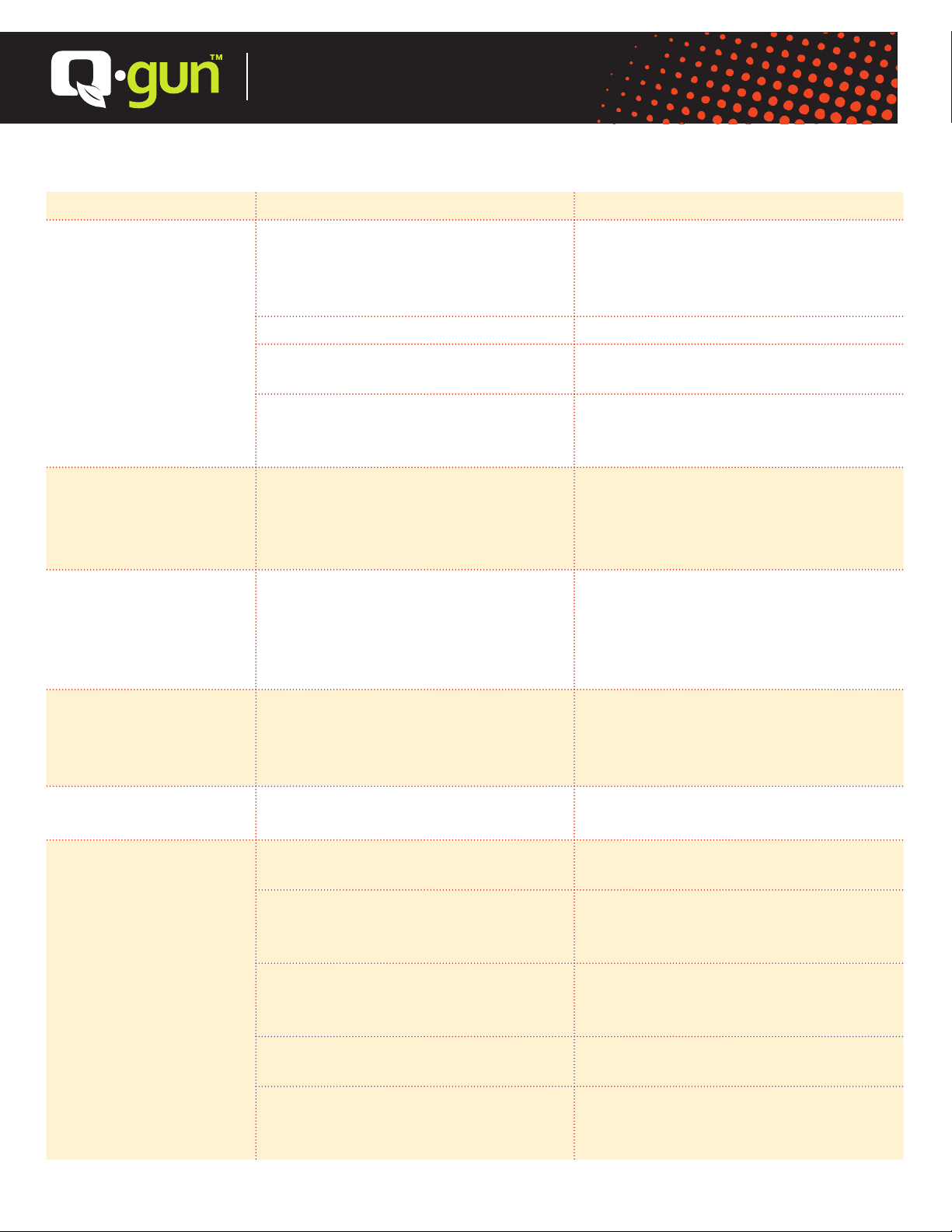

TROUBLESHOOTING

SYMPTOM POSSIBLE PROBLEM SOLUTION

Product will not

dispense when the

handle is squeezed

Incorrect check valve orientation

Verify that both front and rear check

valves are installed correctly - springs

should face forward, in the direction of

flow.

Plugged injection tip Clear injection tip of blockage of debris.

Blockage in lines Inspect tubing for visual debris. Check

tubing ends. Replace tubing if necessary.

Kinked line

Check tubing for kinks or bends that may

restrict flow, and replace tubing if

necessary.

Solution is running

backwards through the

gun and lines

(complete backwards flow)

Check valves are installed backwards Reinsert check valves; springs should

point forward (in direction of flow).

Some solution is

running backward

through the gun

(leaking or backflow)

Check valves are not sealing

May be due to chemical residue build-up,

debris, or worn-out springs. Clean check

valves and gun. Apply silicone grease to

valve cores. Replace check valves if

problem persists.

Fluid leaking from

cylinder Blue O-rings are worn out

Performance may be improved

temporarily with lubrication (NJ Phillips

lubricant). O-rings should ultimately be

replaced.

Leaking from injection

tee handle Injection tip is loose Tighten injection tip. Ensure set screw is in

place, tight.

Slow Injections

Kink or blockage in lines Inspect the tubing to ensure that the lines

are free of kinks or debris.

Product chemistry

The product used may aect uptake time.

More viscous products typically take

longer to inject.

Poor uptake conditions

Poor uptake conditions (very dry to very

wet soils, weather conditions, time of day)

may result in slow uptake.

Dicult-to-inject tree or injection site If uptake is poor with gun operating

correctly, try changing injection sites.

Tips for SLOW tress:

Try changing injection sites on the tree.

Lock the plunger in place using the tension

screw to give your hand a break.

Refer to the table below to troubleshoot the Q-gun. Call our Technical Support at 1-877-272-6747

for additional assistance.

7