4Ordering & Tech Support: 877-272-6747 www.RainbowEcoscience.com

Instructions For Use

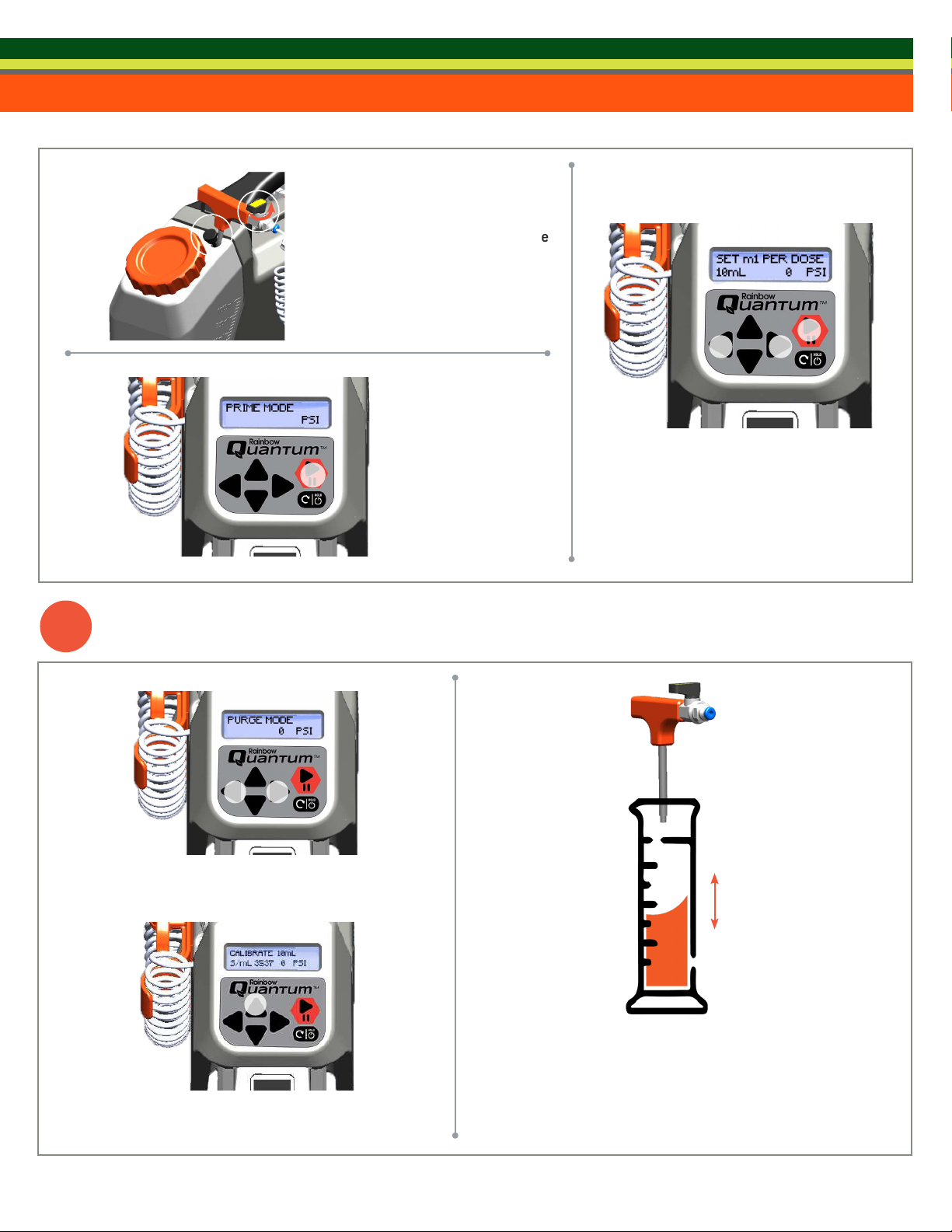

V. Injecting With The Device

1.

Determine number of injection sites by

measuring DBH and dividing by 2.

2. Determine amount of product per injection site by dividing total

amount of product needed for tree by the number of injection sites.

Example: You have a 22 inch tree and are treating at a 5 ml/ in rate

for a total of 110 mls.

110ml total / 11 injection sites = 10 ml dose per injection site

If you have an odd number, adjust the last dose

accordingly.

Example for setting dose: for a tree requiring 89 mls

you will inject (8) 10 ml doses and (1) 9 ml dose,

when you complete the 8th dose you will need to

reset the injection amount to 9 ml and proceed

to inject the remaining ml proceed to inject the

remaining volume. (refer to resetting injection dose

instructions on pg. 5)

3.

DBH

2

To set dose on the device: When device is in injection mode,

use up or down arrows to adjust ml of dose per injection site.

4.

3.

Use the up or down arrows to enter the actual amount

of product injected into the graduated cylinder and

press reset to submit the actual dose.

4.

Repeat the 10 ml calibration dose by pressing start to

inject the now adjusted 10 ml dose into the graduated

cylinder. Continue the above steps 1-3 until the device

distributes an accurate 10 ml dose.

10mL