Table of Contents

Chapter 1 Introduction.......................................................................................................................................1

Overview ..........................................................................................................................................................1

Illumination.......................................................................................................................................................1

Aimer................................................................................................................................................................1

Chapter 2 Installation.........................................................................................................................................2

General Requirements.....................................................................................................................................2

ESD..............................................................................................................................................................2

Dust and Dirt................................................................................................................................................2

Ambient Environment...................................................................................................................................2

Thermal Considerations...............................................................................................................................2

Installation Orientation.................................................................................................................................2

Optics ...............................................................................................................................................................4

Window Placement......................................................................................................................................4

Window Material and Color..........................................................................................................................4

Scratch Resistance and Coating .................................................................................................................4

Window Size ................................................................................................................................................4

Ambient Light...............................................................................................................................................6

Eye Safety....................................................................................................................................................6

Mounting...........................................................................................................................................................7

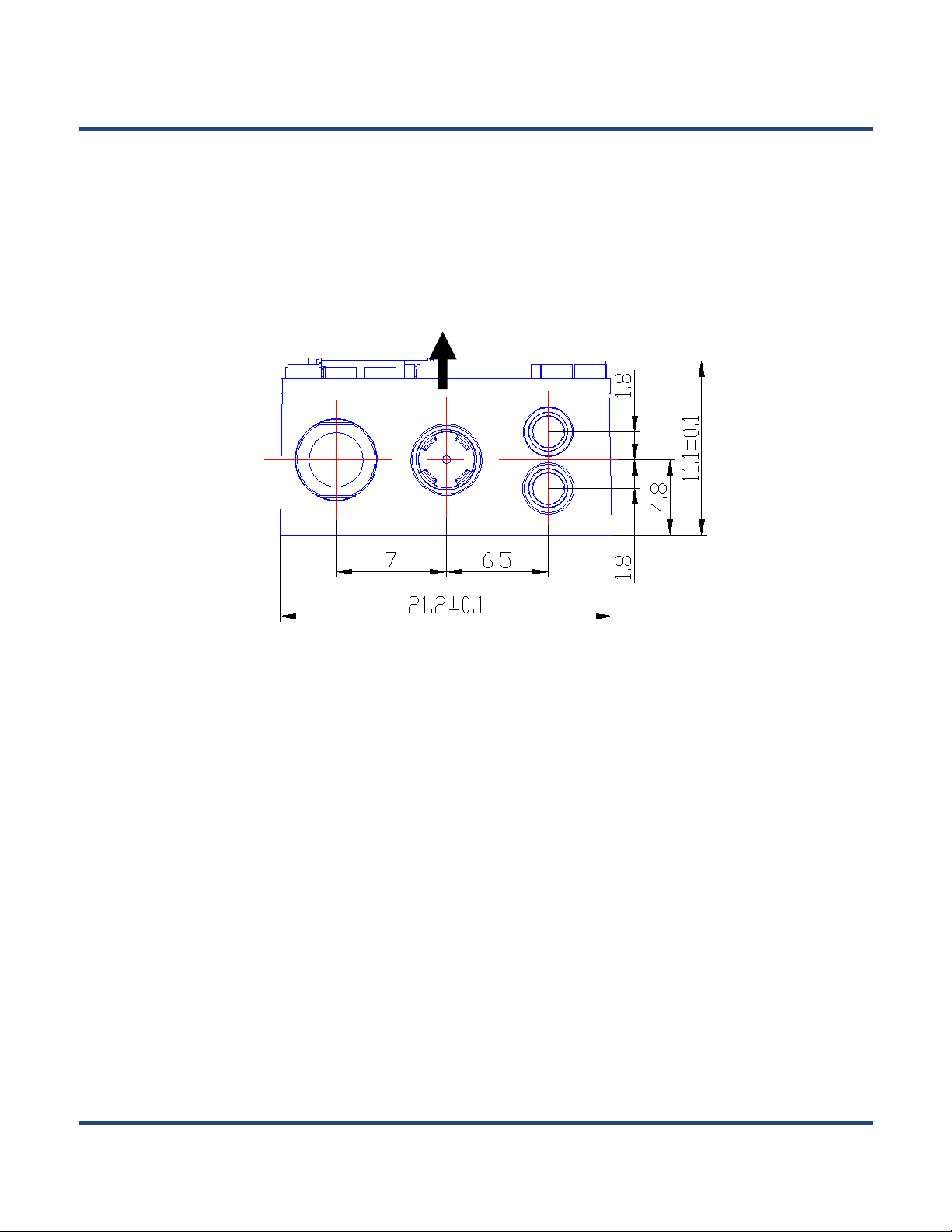

Front View (unit: mm)...................................................................................................................................7

Side View (unit: mm)....................................................................................................................................7

Top View (unit: mm).....................................................................................................................................8

Chapter 3 Electrical Specifications..................................................................................................................9

Power Supply...................................................................................................................................................9

Ripple Noise.....................................................................................................................................................9

DC Characteristics.........................................................................................................................................10

Operating Voltage......................................................................................................................................10