TRAKFAST REPAIR MANUAL

5

Rev. 09/07

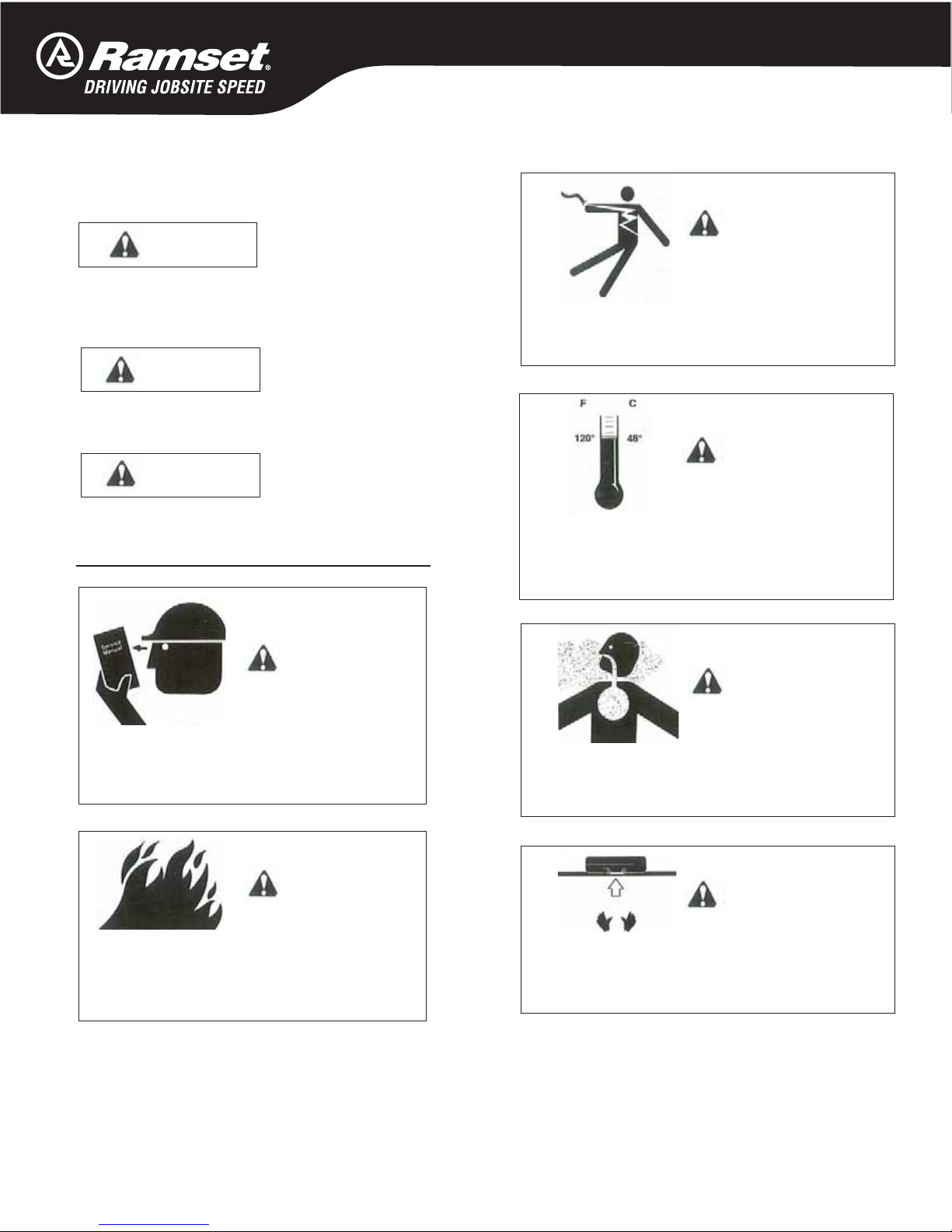

SAFETY INSTRUCTIONS

15. Fuel Cell Storage

16. ALWAYS store the tool with the fuel cell removed.

17. Keep the tool clean.

18. Keep your hands clear of the work area surface.

BATTERY CELL AND CHARGER

1. Keep the battery charger upright for proper opera-

tion.

2. Only charge the battery indoors.

3. Do not charge the battery when the battery tempera-

ture is below 40 degrees F (5 degrees C).

4. Do not use a defective battery charger, one that

overheats and/or smokes when plugged in.

5. Plug the battery charger into a 120V AC outlet only.

A blue light indicates that power is on and that char-

ger circuit is ready.

6. Insert the battery, contact side down, into the

charger and depress red button. The green light will

go out and the red light will come on, indicating the

battery is charging.

7. The green light comes on again when the battery

is fully charged. The time required to fully charge a

battery:

First charge 24 hours

Completely Discharged 3 hours

Partially Discharged Depends on discharge

level of battery

8. Do not allow metal objects to come in contact with

the battery terminals.

9. Do not puncture or attempt to open the battery cell.

10. Do not store the battery in location where tempera-

tures exceed 120 degrees F (48 degrees C).

11. Do not incinerate the Battery.

FUEL CELL

Always store fuel cells where they will not be

exposed to an open flame, sparks or temperatures

above 120 degrees F (48 degrees C).

A fastener may exit at an angle unexpectedly and

cause injury.

DANGER

WARNING

CHEMICAL/EXPLOSION HAZARD

Read ALL instructions before charging or using

the battery. Failure to follow ALL instructions may

result in fire, severe burns and/or release of toxic

materials.

DANGER

DANGER

EXPLOSION/FIRE HAZARD

Read all safety instructions before using or handling the

fuel cell. Failure to follow ALL instructions may result in

explosion or fire. This may cause severe personal injury

or property damage. Keep the fuel cell away from heat,

sparks and open flame. Do not puncture or attempt to

open the fuel cell; it is non-refillable. Do not incinerate,

reclaim or recycle the fuel cell. Exposure to temperature

above 120 degrees F (48 degrees C) may cause the fuel

cell to burst, releasing flammable gas. Do not smoke

while installing/operating the metering valve. Never

spray toward the face or eyes. Do not inhale the spray.

Keep out of the reach of children. Store fuel cell(s) in

well ventilated areas only.

Nickel Cadmium Rechargeable Battery.

Must be recycled or disposed of prop-

erly. NOTE: DEAD BATTERY MUST BE

RETURNED TO YOUR LOCAL TRAKFAST

DISTRIBUTOR FOR PROPER DISPOSAL.

WARNING