Range Road Enterprises Ltd

Box 944

Eckville AB T0M 0X0

www.range-road.ca www.range-road.com

Instructions

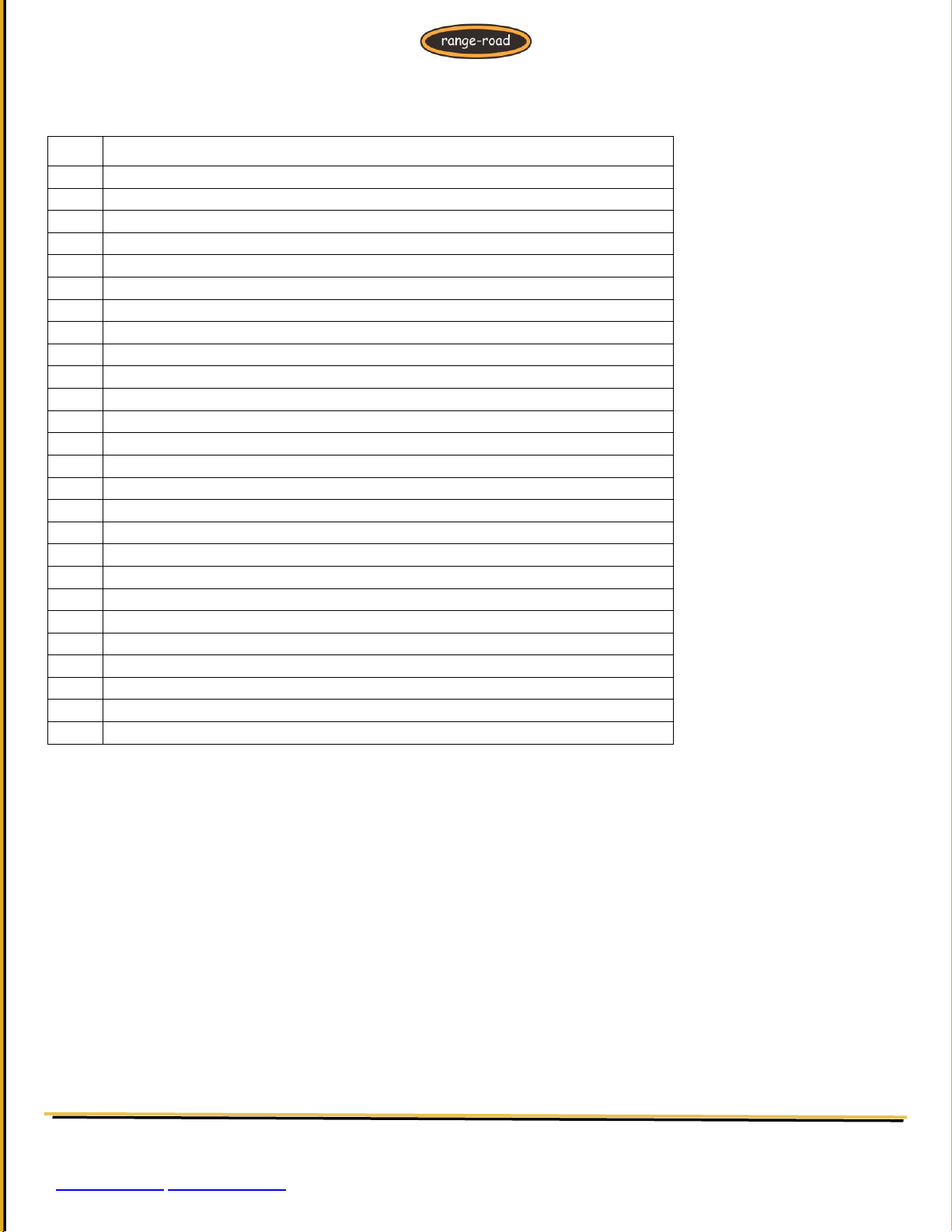

1. Saw blade installation

First retract the adjustment lever 19 a short distance, then twist the pressure roller bracket 10 to the right,

release 15, and then lift the compactor handle 13, rotate 90°, then open the pressure plate 20, put the saw

blade in and adjust the position of the saw blade with 16 so that the saw tooth tip connecting line and the

edge of the pressing plate are parallel and the bottom line of the saw blade is positioned 2-3 mm from the

edge of the pressing plate. Cover the plate, tighten the saw blade, and rotate the compactor to the center of

the plate. Rotate the pressure roller bracket to press the pressure roller 9 against the saw blade.

Attention: As shown in the figure, the angle between the axis of the pressure roller 9 and the advancing

direction of the saw blade must not be greater than 90°, so that the blade can always be placed against the

blade bar 16 when it advances, and will not be deflected. The angle of the blade can be adjusted by 7.

2. Adjusting the angle of the table

Loosen the screw 15 on the compactor support and the table plate 21 can be rotated. The angle of rotation

depends on the size of the saw tooth angle (generally the front of the saw tooth can be placed against the

inner side of the grinding wheel.) After the angle is adjusted, tighten the screws 15 to secure the table.

3. Grinding wheel dressing

If the angle of the bevel on the grinding wheel is off from the angle of the saw tooth, it should be dressed.

Trimming can be done with a diamond pen, or a hard ceramic wheel can be used.

4. Pushing tooth position adjustment

The general rule for grinding teeth is: which tooth is used to push the tooth to be ground. This requirement

can be achieved by adjusting the hand wheel 26.

5. Adjust only one tooth at a time (tooth distance adjustment)

Rotate the handle 2 to adjust the number of teeth that the push-tooth hook pushes each time. Generally when

the tooth is ground, the push hook pushes only one tooth at a time.

6. Grinding the back of the tooth

If the back of the tooth is to be ground, this can be achieved by adjusting the relative positions of the cams 17

and 18. This step needs to be performed after the first five steps have been completed. The specific operation

is: stop state, loosen the screw on the cam 18, and point the pointer on it to the scale 5, and then tighten the

screw, then turn the cam by hand to observe the contact between the back of the tooth and the grinding

wheel when pushing the tooth. If it is not in contact, loosen the screw again, so that the index of the pointer

on the cam 18 is increased. (If the contact is too tight, the index must be made smaller.) When the cam is

rotating (during the feed, for example), the front of the serration and the tooth when the back side is in light

contact with the grinding wheel, the adjustment is basically in place. At this time, you can start the machine

and observe.

Note: Before turning on the power, first adjust the lever 19 back a short distance, and then slowly feed it to

prevent the saw tooth from being worn out.