9040 Low Voltage Control Unit Kit- Introduction

INTRODUCTION

DESCRIPTION

The Ransburg spray Process

The

Ransburg Spray Process

is an air atomized

method for applying coatings to objects

electrostatically. This system applies a high

voltage DC charge to the applicator nozzle

electrode, creating an electrostatic field

between the atomizer and the target object. The

target is electrically grounded through its

support that may be either stationary or moving.

A regulated pressure fluid system delivers coating

material to the atomizer. At the atomizer, air is

applied that atomizes the coating material forming a

spray mist that, under the influence of the

electrostatic field, becomes electrically charged. The

charged particles are attracted to, and deposited on,

the target object. The forces between the charged

particles and the grounded target are sufficient to

turn most normal overspray around and deposit it on

the side and back surfaces of the target. Therefore,

a high percentage of the spray is deposited on the

target.

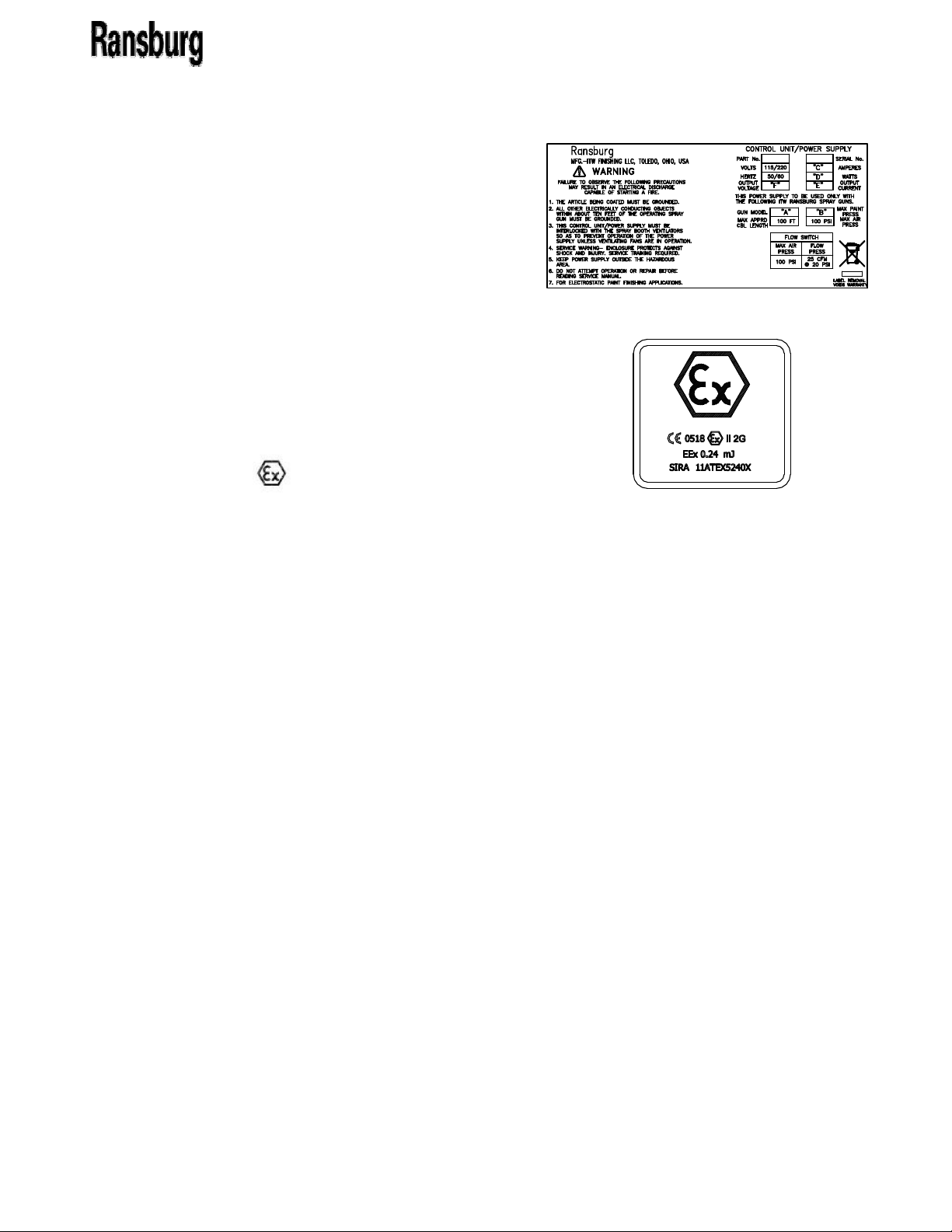

9040 Cascade Low Voltage

Control Unit Kit

The

9040 Cascade Control Unit

converts standard

AC line voltage to a high frequency, low voltage

signal ranging from 0 to 10 Vrms. This signal is

supplied to an external cascade through a low

voltage cable. The external cascade converts the

low voltage signal into a high voltage. This high

voltage is transmitted through the cable to the

applicator. At the applicator an electrode in the

applicator creates a DC high voltage field the

spray goes through and picks up the electrostatic

charge. When the material is directed to a

grounded target, more material is attracted to the

target yielding higher painting efficiency.

The voltage/current characteristic is designed to

optimize the charging process under varying load

conditions, and to limit the operating current to a

safe maximum value.

In addition to supplying low voltage output to the

applicator, the 9040 Cascade control unit also

provides controls for AC power ON/OFF, infinite

high voltage adjustment, a high voltage meter, a

current meter, an AC power ON indicator, a high

voltage ON indicator, a cable fault indicator, and a

current overload indicator and reset switch.

Additionally, output terminals are provided for

remote overload reset, analog current output, and

high voltage control. Interlock connections for a

conveyor and exhaust fan are also provided. A

combination triple setpoint/analog input control

board is also supplied with 9040 Cascade control

units powering automatic spray applicators.

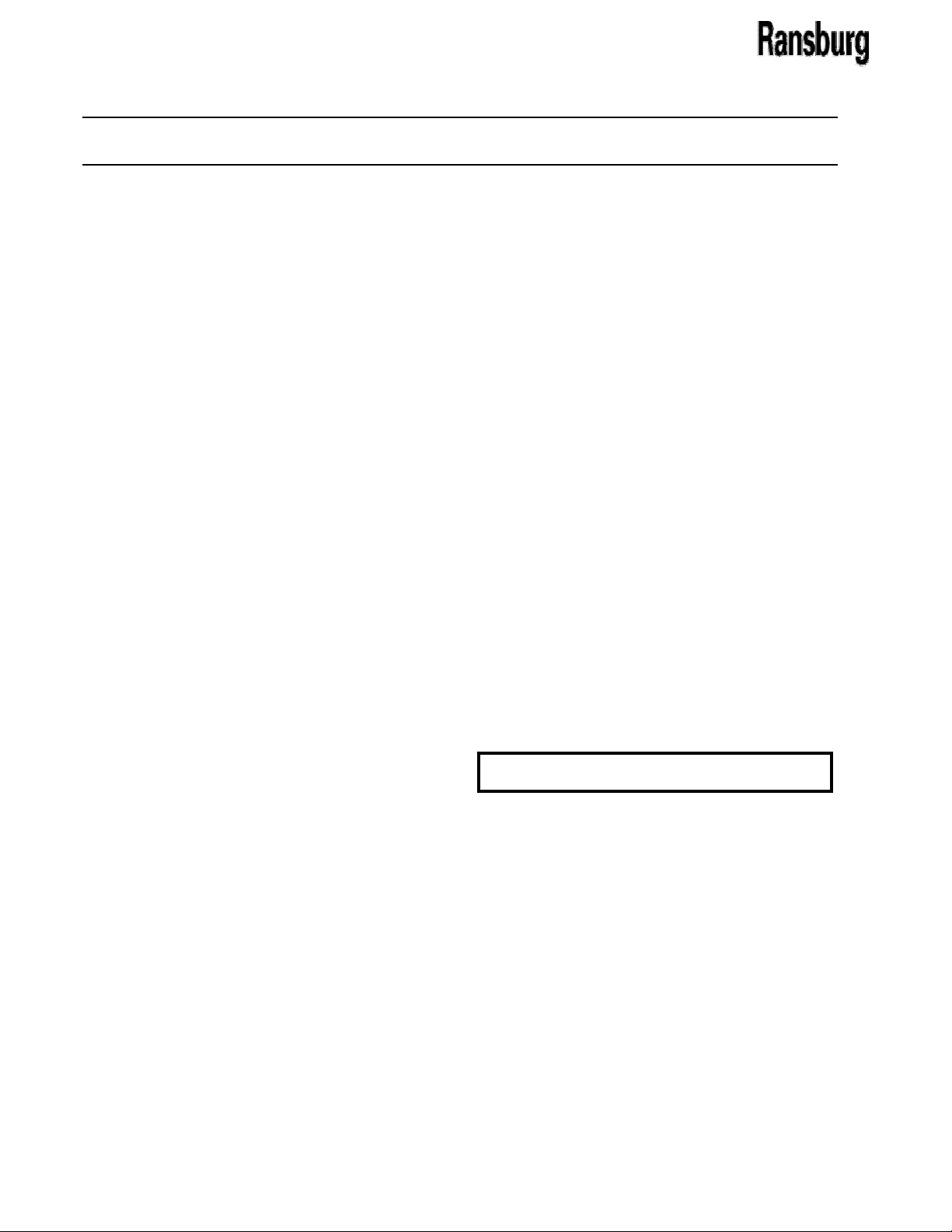

9040 Cascade Low Voltage

Control Unit Kit 80072 and

80078

The 9040 Cascade Low Voltage Kit 80072-XXX

and 80078-XXX are designed to be used with

either the Esta-Quick Applicator (AEMD 500) or

the Evolver SE product (A12455-XXXX). The

difference in the units is the 80072-XXX has a

potted cascade where the 80078-XXX has an oil

filled cascade.

The only combination of units that carry any

approval is the AEMD500 used with the 80072-

XXX units as described in this manual. Any other

combination of applicator and 9040 unit does not

have any agency approval associated with it.

When using equipment that is not approved, the

user needs to be aware of the code requirements

needed to operate safely. If there is any question

regarding safe installation requirements when

using this product, refer to European Norms (EN

50 176) or NFPA-33.

7

CP-11-01

Note