EN

VTS reserves the right to implement changes without prior notice

User’s Manual 1

Table of Content

USER’S MANUAL................................................................................................ 3

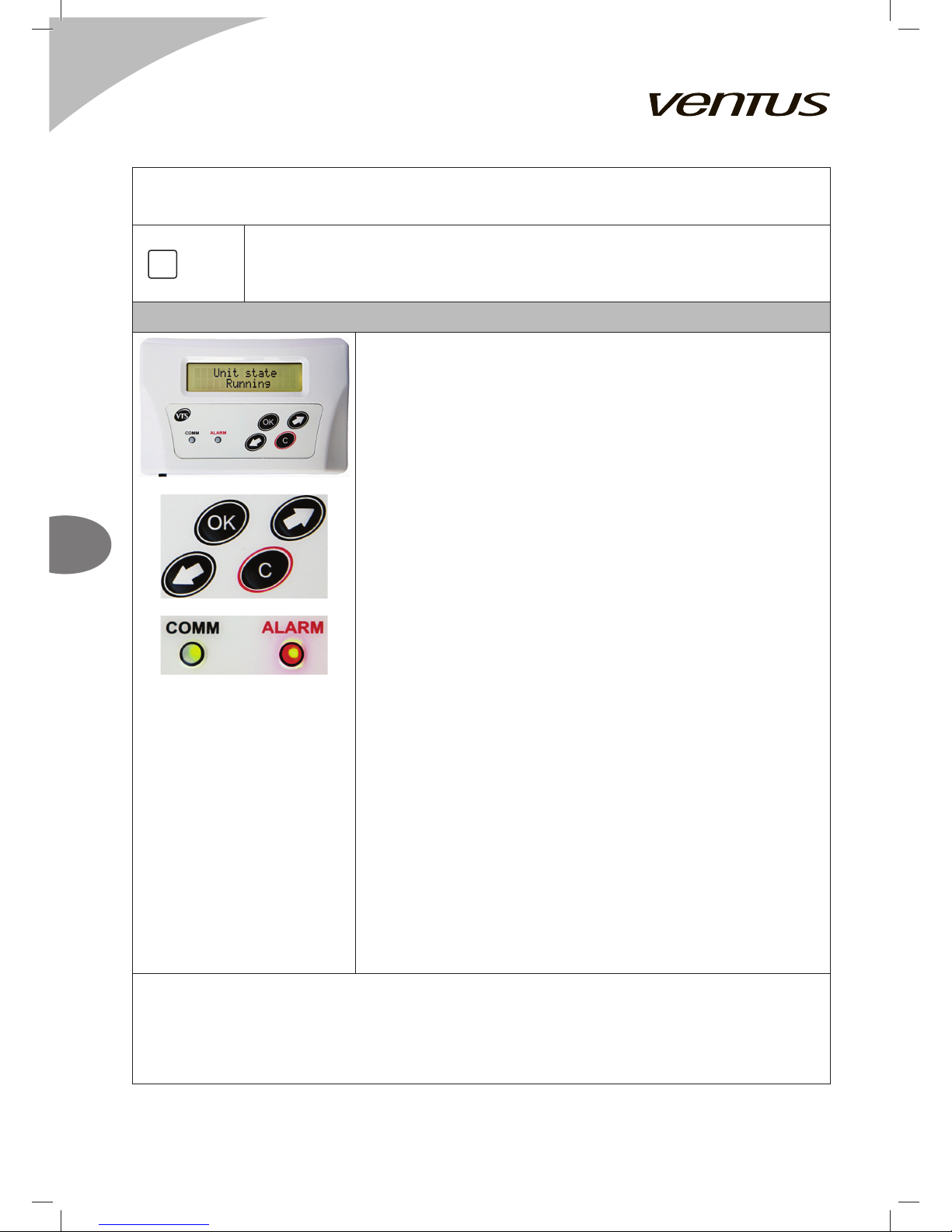

1. DESCRIPTION OF CONTROLS ............................................................................................................................................ 3

INTRODUCTION ........................................................................................................................................................................ 3

MAINS SWITCH ......................................................................................................................................................................... 3

SIGNALLING CONTROLLER STATUS ..................................................................................................................................... 3

CONTROL PANEL HMI OPTIMA .............................................................................................................................................. 4

SYSTEM START-UP .................................................................................................................................................................. 5

SWITCHING ON POWER SUPPLY............................................................................................................................................ 5

QUICK START ........................................................................................................................................................................... 5

2. APPLICATION BASICS ......................................................................................................................................................... 6

MAIN MENU STRUCTURE ....................................................................................................................................................... 6

HMI OPTIMA SETTINGS & CONNECTING TO THE CONTROLLER ..................................................................................... 7

LANGUAGE SELECTION English / Polski / Русский ............................................................................................................... 8

ENTERING THE PASSWORD .................................................................................................................................................. 8

3. CALENDAR ........................................................................................................................................................................ 8

CALENDAR ANNUAL ....................................................................................................................................................... 9

CALENDAR MONTHLY .................................................................................................................................................... 9

CALENDAR WEEKLY ....................................................................................................................................................... 9

CALENDAR DAILY ............................................................................................................................................................ 9

CALENDAR EXAMPLE ............................................................................................................................................................10

4. PARAMETERS ..................................................................................................................................................................11

PARAMETERS TEMPERATURES ..................................................................................................................................11

PARAMETERS DAMPERS ..............................................................................................................................................12

PARAMETERS FANS ......................................................................................................................................................12

PARAMETERS WATER HEATER ...................................................................................................................................12

PARAMETERS ELECTRIC HEATER ..............................................................................................................................12

PARAMETERS WATER COOLER ..................................................................................................................................12

PARAMETERS DX COOLER STATUS ...........................................................................................................................13

PARAMETERS COOLER ................................................................................................................................................13

PARAMETERS PREHEATER .........................................................................................................................................13

PARAMETERS UNIVERSAL COIL .................................................................................................................................13

PARAMETERS RECOVERY RATE .................................................................................................................................14

PARAMETERS ROTARY REGEN. ..................................................................................................................................14

PARAMETERS MIXING RATE .........................................................................................................................................14

5. SETTINGS ........................................................................................................................................................................14

SETTINGS DEF. WORK MODE ......................................................................................................................................14

SETTINGS STANDBY MODE .........................................................................................................................................14

SETTINGS SEASON .......................................................................................................................................................15

SETTINGS PERFORMANCE ..........................................................................................................................................15

SETTINGS TEMP. REGULATOR ....................................................................................................................................16

SETTINGS DAMPERS ....................................................................................................................................................16

SETTINGS FANS .............................................................................................................................................................17

SETTINGS HEATER ........................................................................................................................................................17

SETTINGS PREHEATER ................................................................................................................................................19

SETTINGS CLG PUMP PROT. ....................................................................................................................................... 20