ENG ISH

9

IMPORTANT REMARKS

For any installation problem please contact our Customer Service

at the number +39-0172.812411 operating Monday to Friday

from 8:30 to 12:30 and from 14:00 to 18:00.

V2 has the right to modify the product without previous notice;

it also declines any responsibility to damage or injury to people

or things caused by improper use or wrong installation.

m Please read this instruction manual very carefully before

installing and programming your control unit.

• This instruction manual is only for qualified technicians, who

specialize in installations and automations.

• The contents of this instruction manual do not concern the

end user.

• Every programming and/or every maintenance service should

be done only by qualified technicians.

AUTOMATION MUST BE IMP EMENTED IN COMP IANCE

WITH THE EUROPEAN REGU ATIONS IN FORCE:

EN 60204-1 (Machinery safety. electrical equipment

of machines, part 1: general rules)

EN 12445 (Safe use of automated locking

devices, test methods)

EN 12453 (Safe use of automated locking

devices, requirements)

• The installer must provide for a device (es. magnetotermical

switch) ensuring the omnipolar sectioning of the equipment

from the power supply. The standards require a separation of

the contacts of at least 3 mm in each pole (EN 60335-1).

• After making connections on the terminal board, use one

hose clamp to fix dangerous voltage wires near the terminal

board and another hose clamp to fix safety low voltage wires

used for accessories connection; this way, in case of accidental

detachment of a conducting wire, dangerous voltage parts

will not come into contact with safety low voltage ones.

• The plastic case has an P55 insulation; to connect flexible or

rigid pipes, use pipefittings having the same insulation level.

• nstallation requires mechanical and electrical skills, therefore

it shall be carried out by qualified personnel only, who can

issue the Compliance Certificate concerning the whole

installation (EEC Machine Directive 89/392, Annex A).

• The automated vehicular gates shall comply with the

following rules: EN 12453, EN 12445, EN 12978 as well as

any local rule in force.

• Also the automation upstream electric system shall comply

with the laws and rules in force and be carried out

workmanlike.

• The door thrust force adjustment shall be measured by means

of a proper tool and adjusted according to the max. limits,

which EN 12453 allows.

• Connect the earthing lead of the motors to the

electricity grid earth system.

• Observe all necessary precautions (e.g. anti-static

bracelet) for handling parts sensitive to

electrostatic discharges.

DEC ARATION OF CONFORMITY

V2 S.p.A. hereby declare that products EASY-TOP conform to the

essential requirements established in the following directives:

-2004/108/CEE (EMC Directive in accordance with standards

EN 55014-1, EN 55014-2, EN 61000-3-2, 61000-3-3)

- 2006/95/CEE (Low Voltage Directive in accordance with

standards EN 60335-1 + EN 60335-2-103)

- ROHS2 2011/65/CE

Racconigi, lì 28/01/2014

V2 S.p.A. legal representative.egale della V2 S.p.A.

Cosimo De Falco

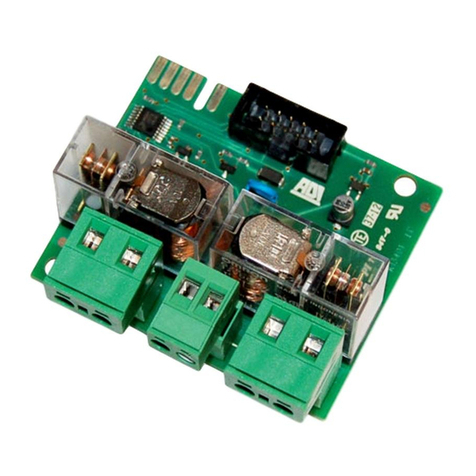

DESCRIPTION OF THE CONTRO UNIT

The EASY-TOP digital control unit is an innovative V2 product

that guarantees safety and reliability for the automation of roller

shutters.

• 230 Vac output for 1 single-phase motor

• 230 Vac output for flashing light or timed courtesy light

• Plug-in adaptor for modular radio receiver MR2

• nput for key switch or pushbutton (START)

• nput for separate UP/DOWN commands

• nput for safety pushbutton (STOP)

• nput for safety photocell with automatic operating test

(PHOTO)

• Sensitive edge safety input (EDGE): can connect to a

mechanical or resistive rubber edge with automatic operation

test or to an optical edge with 30V DC power supply and by

adjusting the transmitter power

• nputs for limit switches (FCA-FCC) that can be used as an

alternative to the EDGE and F RE inputs

• nput for fire emergency or theft (F RE)

• Monitoring of the inputs on the display

• Logic of operation and programmable work times using the

keyboard and display

• Possibility of operating in DEAD MAN mode

TECHNICA

SPECIFICATIONS 230V models 120V models

Power supply 230V / 50Hz 120V / 60Hz

Max motor load 1100W 600W

Max accessories load

30 Vdc 3W 3W

Working temperature -20 ÷ +60 °C -20 ÷ +60 °C

Protection fuse F1 = 5A delayed F1 = 5A delayed

Dimensions 170 x 185 x 70 mm

Weight 800 g

Protection P55