3

Please read this user manual carefully before using the device

and keep it for future reference.

Following the manual's recommendations guarantees long-lasting and

failure-free exploitation of the device.

IT IS FORBIDDEN

1. Make repairs on your own and fail to comply with the rules contained in

this manual regarding the connection and operation of the device;

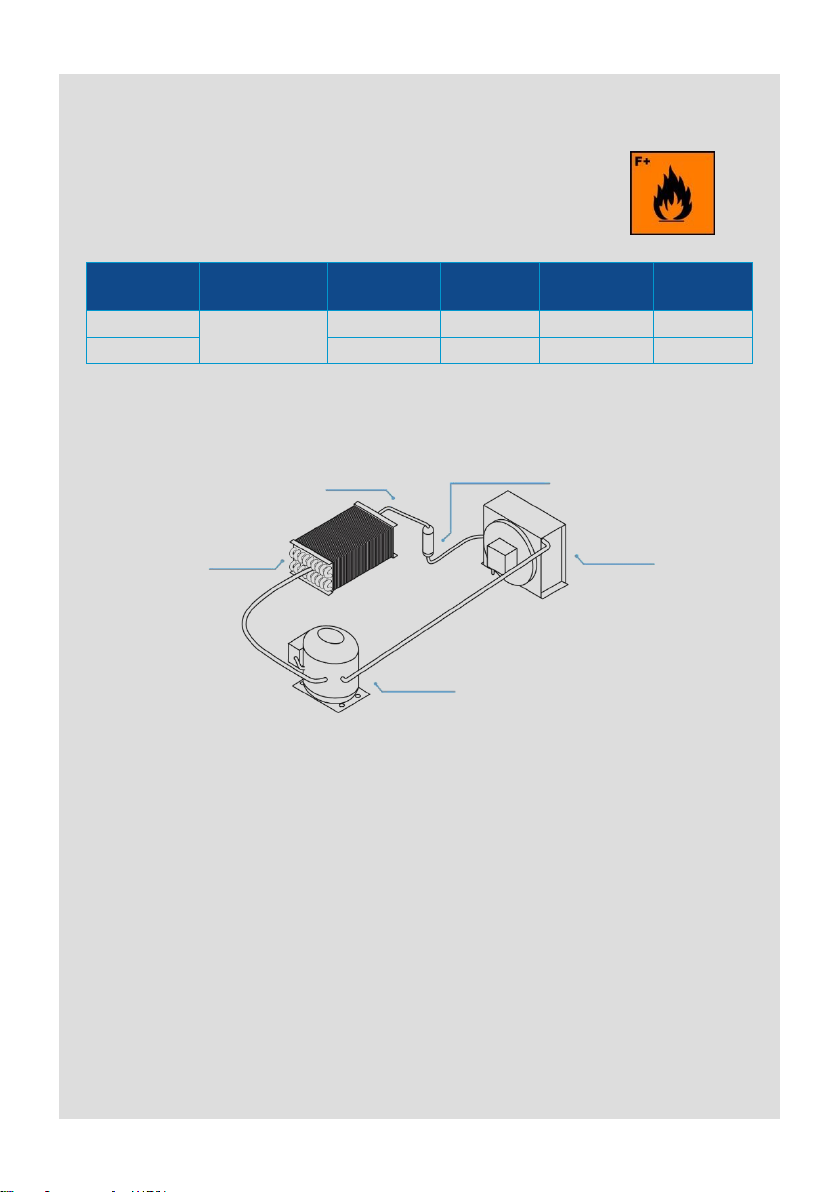

2. Store substances that may explode in the device, such as aerosols

filled with combustible propellants;

3. Place the device in the sun;

4. Covering the inlet and outlet of air from the aggregate;

5. Switching the device on to the mains without a properly

functioning protective circuit system;

6. Use of extension cords and dividers to connect power.

7. Use devices/objects that could cause an electric spark inside

the device and in the aggregate chamber.

WARNING!

1. Incorrect connecting of the device to the mains may result in an

electric shock.

2. In the event of sparks or breakdowns, immediately disconnect the

device from the power supply by pulling the plug from the socket and

calling an authorized service technician.

3. It is necessary to protect the wiring system and control system

against water and mechanical damage.

4. When servicing and replacing parts, the device must be

disconnected from the power supply

5. Power cord is connected directly with sockets mounted on the

device. The aggregate and lighting switches do not disconnect current

voltage into the socket.

CAUTION!

1. Before cleaning the condenser –switch the device off!

2. When cleaning the condenser, do not use tools/objects that could

cause an electric spark.

3. Water condensation on glass panes and sheets at high relative

humidity (over 60%) is a natural phenomenon. Long-term and frequent

occurrence of dewing indicates inadequate ambient conditions and is

not a basis for calling the service!

4. Take care when removing the glass panes.

Breaking the glass panes can cause injury!

The device is not intended for household use.

The device is not intended for outdoor use.