2

REPLACING THE THERMOSTAT

WARNING: Danger of shock. Be sure to turn power o.

Use ONLY Raritan replacement thermostat

(#WH16 ignition protected).

1. Remove access panel to thermostat and element.

2. Remove cover (personnel protector).

3. Unscrew the neutral and hot wires from the element with

a Phillips screw driver.

4. Cut the incoming wires. Pull tabs of thermostat mounting

bracket forward and lift thermostat out.

5. Install new thermostat.

6. Strip incoming wires, exposing 5/16" (8mm) of wire.

7. Crimp neutral wire supply to white wire and hot wire

supply to black wire (series connector provided with new

thermostat).

8. Screw ring terminals of white and black wires on lower

side of thermostat to studs of the element.

9. Reinstall personal protector panel.

NOTE: Check for leaks before proceeding.

10. Replace access panel.

11. Turn on AC power.

L206 0420jlc

2

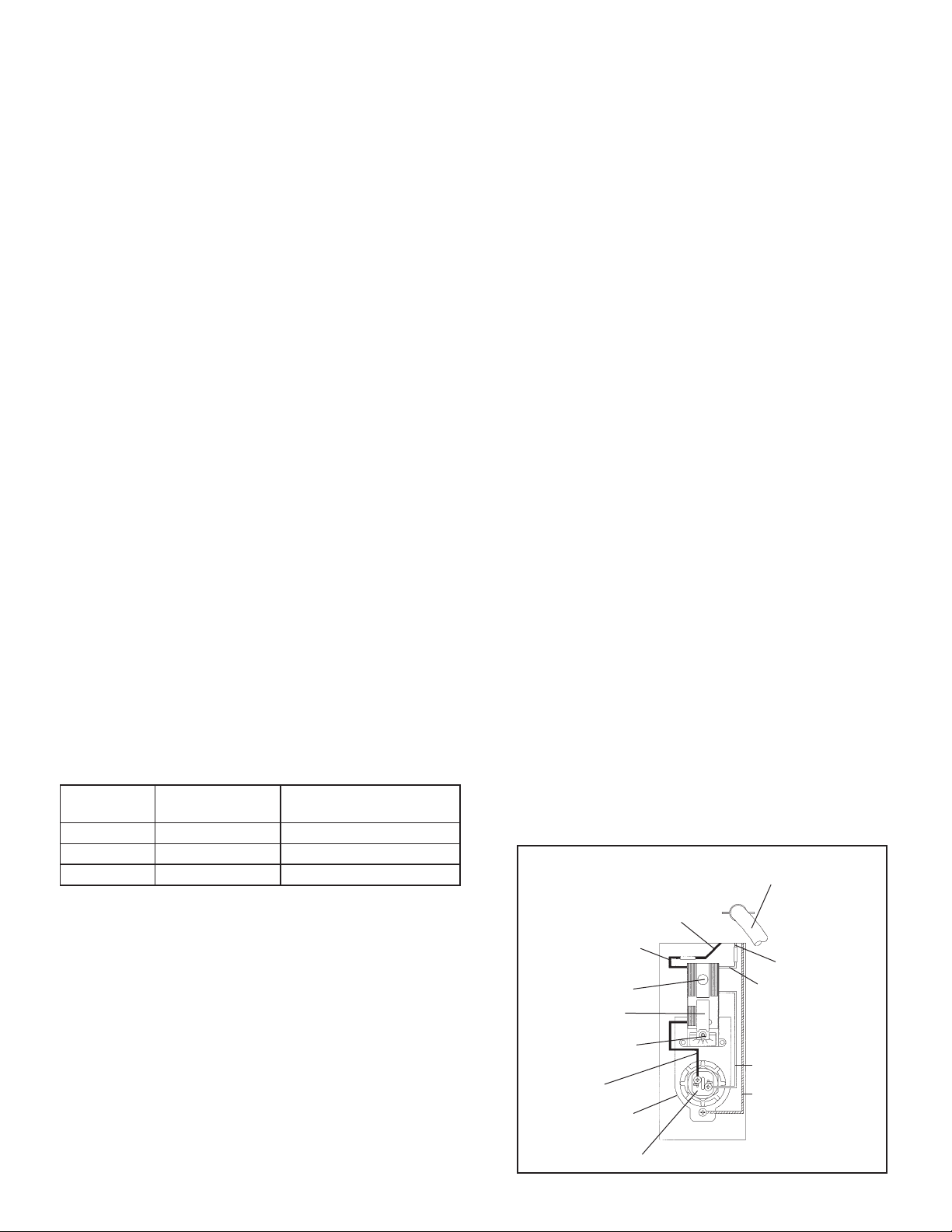

FIG 1

MAINTENANCE

Following installation, temperature and pressure relief lever

MUST be operated by lifting lever up AT LEAST ONCE A

YEAR to ensure that the water ways are clear. Certain naturally

occurring mineral deposits may adhere to the valve, rendering

it unoperative. When manually lifting the lever up, water will

discharge and precautions must be taken to avoid contact with

hot water and to avoid water damage. BEFORE lifting lever

up, check to see that a discharge line is connected to this valve

directing the ow of hot water from the valve to a proper

place of disposal, otherwise personal injury from hot water

or steam may result. If no water ows, valve is inoperative.

TURN OFF THE WATER HEATER AND REPLACE THE

VALVE IMMEDIATELY.

If a backow preventer such as a check valve is installed in

cold water line and temperature and pressure valve discharges

a cup of water per 10 gallon capacity of water heater during

heating, reason for this occasional discharge is thermal

expansion of water in closed system. An expansion tank

should be installed in cold water line after check valve to

correct such occasional discharge or dripping of temperature

and pressure valve (See FIG 2).

Inspection of Anode and proper winterization is required

of the Raritan Water Heater. Periodic visual inspection is

recommended to be sure connections are tight, wires are

not frayed and the unit is properly grounded. DO NOT use

solvents to clean heater jacket. Incorporate this inspection

into commissioning procedure in spring and winterizing

procedure in fall.

A removable magnesium Anode is integral with the hot water

discharge tting. The Anode should be checked frequently

depending on hardness of water by removing it from the

water heater. Initially after installation, check within a year

and depending on water quality frequency can be reduced to

every 3 to 5 years. If the Anode diameter is less than 3/8"

(9.5 mm), it should be replaced. If discoloration, unusual

smell or taste develop in the water, inspect or replace Anode.

The Anode is replaceable as a unit and may be ordered from

Raritan dealers or from the factory. Please specify part number

1790610 for 6 gallon model and part number 1790010 for 12

and 20 gallon models.

REPLACING THE ANODE IN RARITAN

WATER HEATERS

4. When water stops owing out, remove any piping or

ttings from hot water “out” nipple tting (see FIG 1).

5. Remove plastic nish washer to reveal unthreaded

area of nipple. Remove nipple with pipe wrench. Note

that magnesium rod extends well into water heater and

adequate clearance must be available to remove it.

11" for 6 gallon tanks and 16" for 12 and 20 gallon tanks.

6. Apply pipe PTFE thread compound or thread tape

to new anode and screw into water heater tank.

Tighten securely with pipe wrench. Re-connect all

external plumbing.

7. Close temperature and pressure relief valve and turn

on pressure pump.

8. When pump has come up to pressure and shut o,

check for leaks, then restore electric power.

1. Turn o electric power to water heater.

2. Turn o pressure pump and open faucets to bleed

pressure from water system. When water stops, close

faucets.

3. Open pressure and temperature relief valve to allow

water level in water heater to drop below level of

valve.

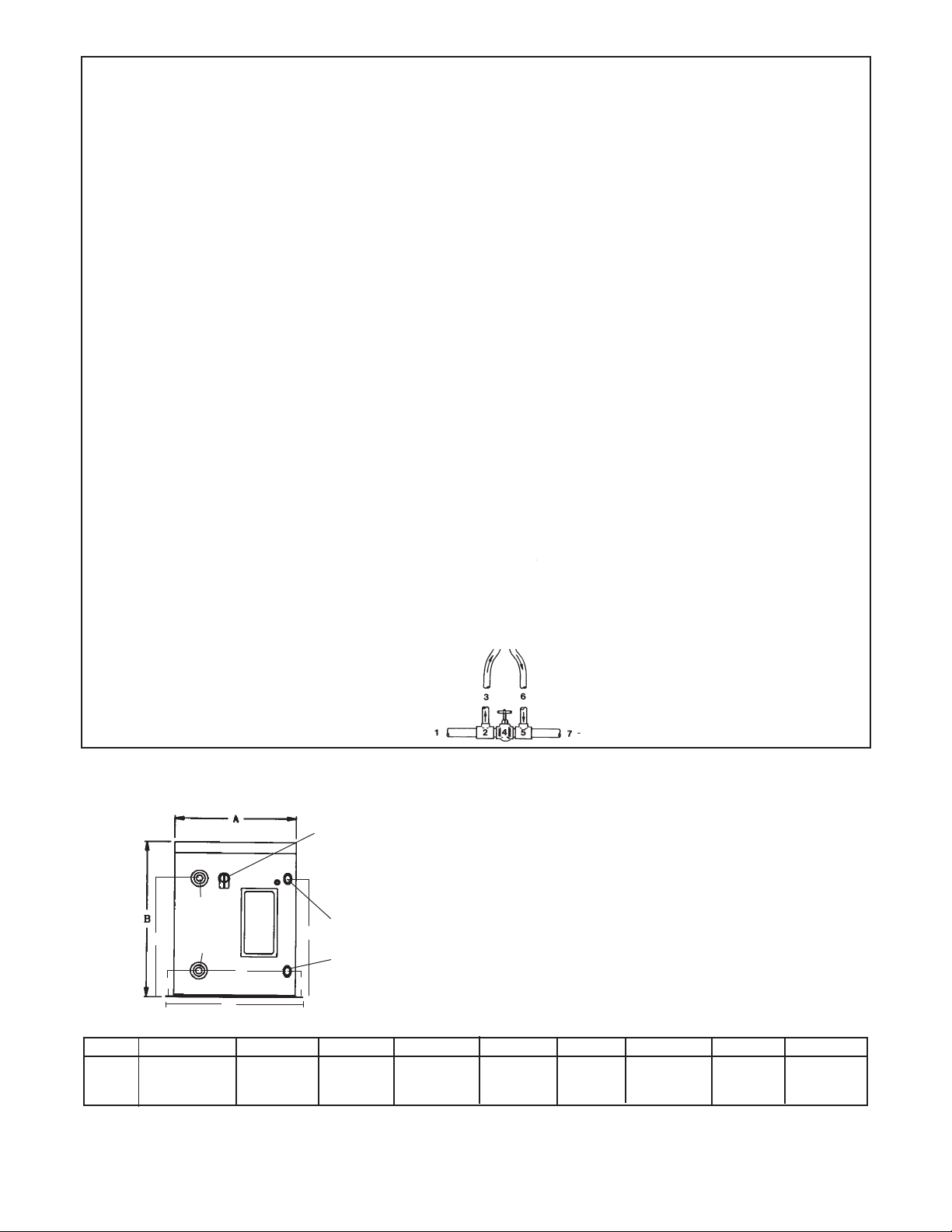

Plastic nish washer,

press this in to reveal

unthreaded portion of

nipple

TEMP./PRESS.

RELIEF VALVE

HOT

COLD

Unthreaded section

of anode nipple - grip

with pipe wrench to

remove and re-install

ANODE

Plastic nish washer.

Remove washer from

anode this will reveal

unthreaded portion of

nipple