2

OPERATION

Designed to empty marine and RV holding

tanks of normal waste and sh boxes of scales

and residual waste. The unique dual-cut blade

design ensures waste is ground up thoroughly.

Marine pump out must be in proper discharge

zones only. This macerator will not handle hard

objects, rags, or feminine napkins.

e optional Smart Macerator Control (SMC)

monitors pump motor and prevents pump

damage due to priming failure or dry running.

It also protects motor against overload. If power

to control is not turned o, smart control will

prevent impeller sticking by jogging impeller

once every seven days of non- use.

PUMP IS INTERMITTENT DUTY ONLY!

• Make sure Waste valve to pump and discharge

valve [if equipped] are both open. Turn on

momentary switch and pump out tank.

• When tank is empty, pump will get louder

with a high pitch sound. Immediately turn

pump o, or damage to impeller and housing

will occur. If pump is equipped with SMC,

pump will turn o after 5 seconds of dry

running

• If not equipped with SMC, do not run pump

dry for more than 15 – 20 seconds. Flush

tank and pump with water after each use.

This macerator will handle normal waste,

tissues, cigarettes, sh scales, etc. It is not

designed to handle large hard objects such as

large bones or fruit pits.

Periodic Maintenance and Storage: Flush

with water after each use. Check wire connec-

tions occasionally. After periods of non-use,

impeller can stick. To loosen, open rear shaft

cover and turn motor shaft clockwise with a at

tip screwdriver. Then replace shaft cover. For

extended periods of non-use, pump impeller can

be lubricated by running a small amount of min-

eral oil through holding tank system.

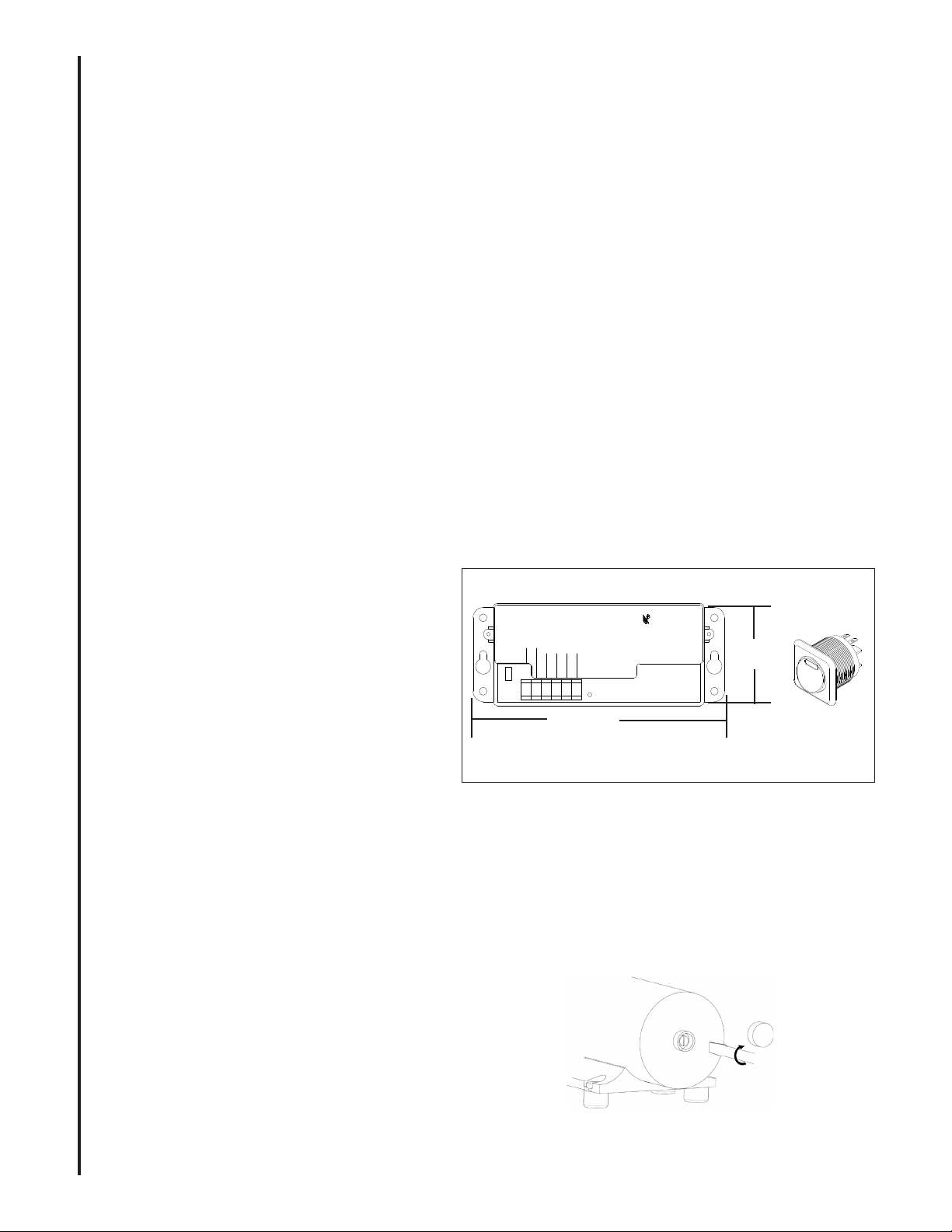

Maintenance: Turn o all power!

Rear end cap/ motor shaft slot access:

Remove cap over the shaft

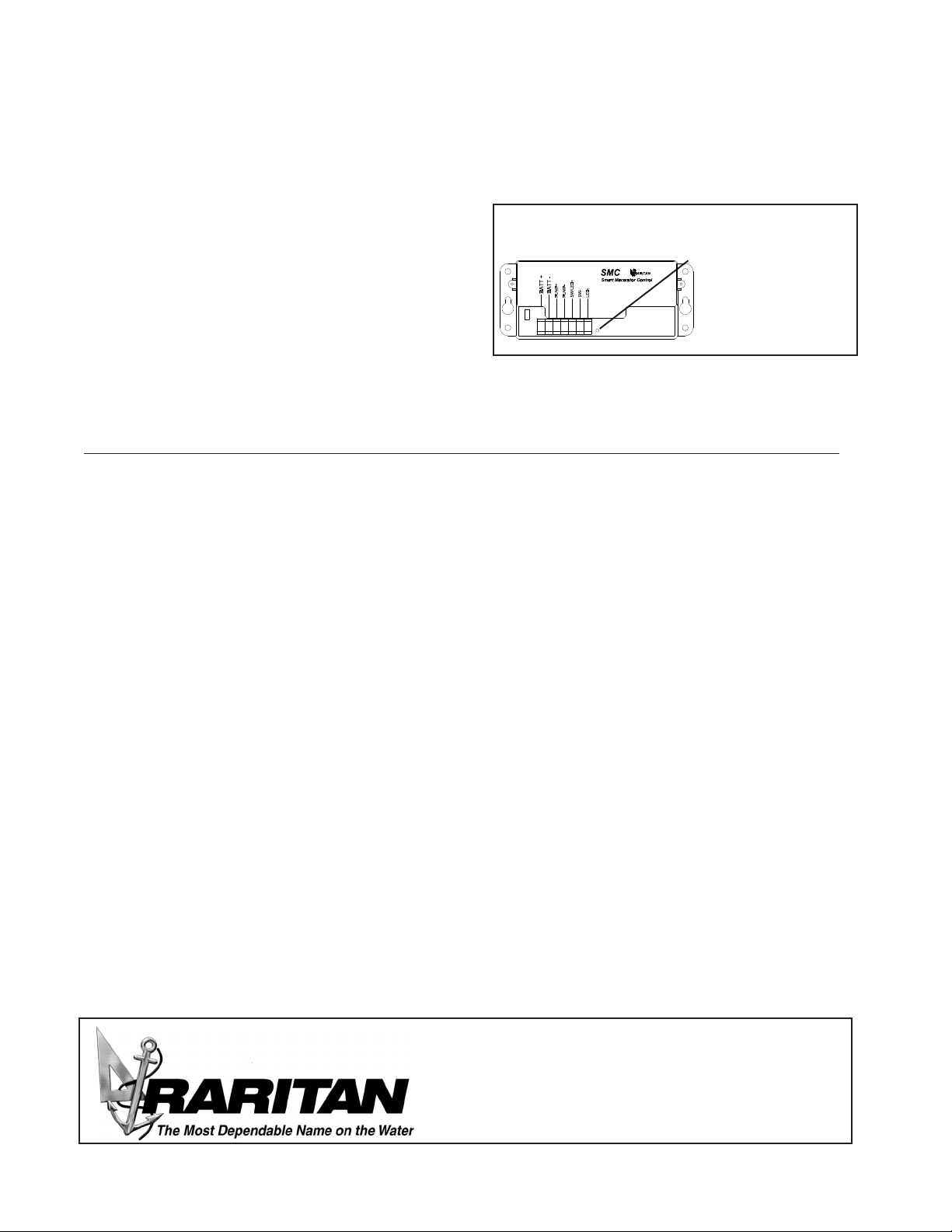

Smart Macerator Control (SMC) (optional)

SMC monitors motor and pump to prevent dry

run and overload.

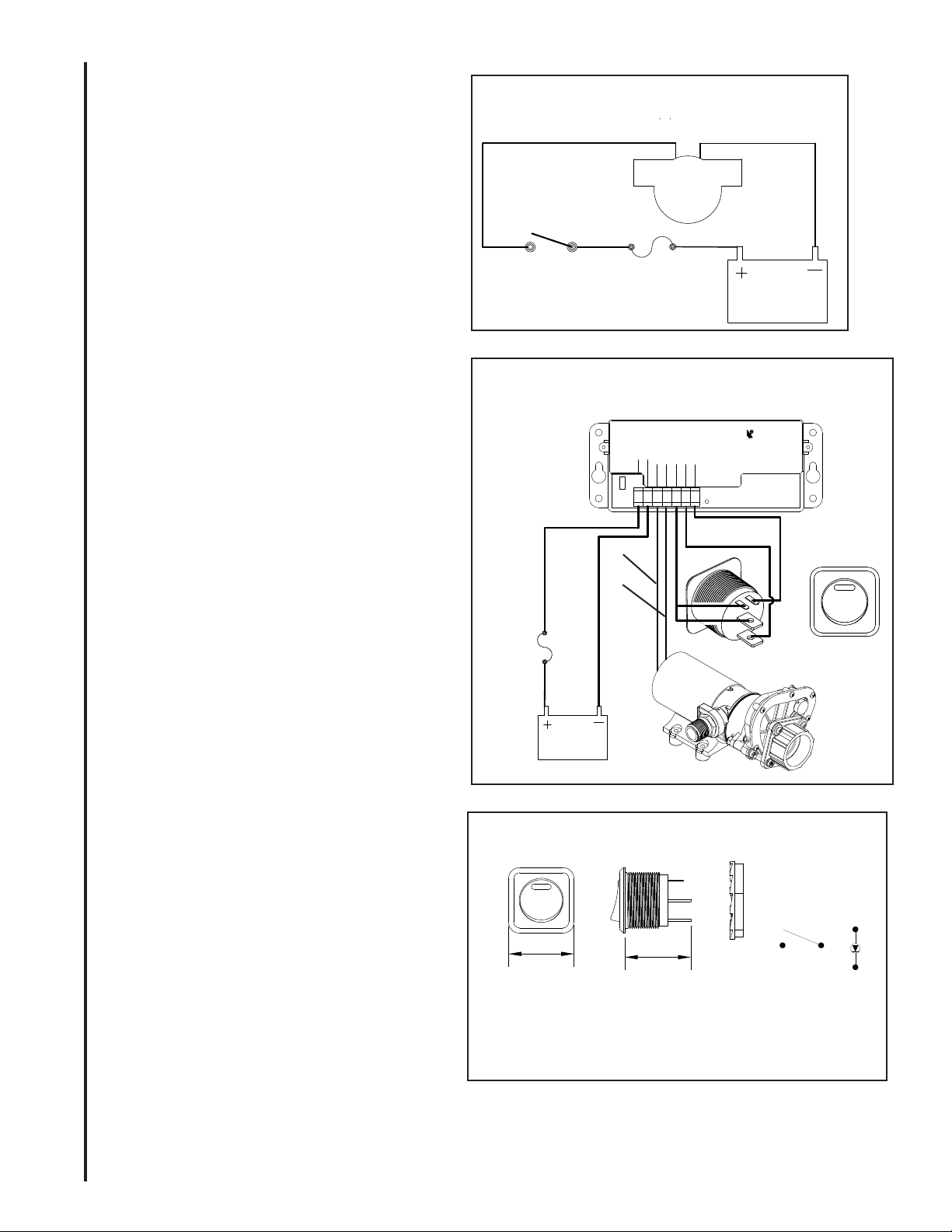

Turn on switch (ESR03A) to activate Macerator

Pump.

SMC control has following features:

1. If pump does not prime within 7 seconds,

SMC control will shut down the pump.

2. If pumps runs dry for 5 seconds, SMC

control will shut down the pump.

3. If pump draws more than 20 amps, control

will shut down pump.

4. LED at the switch and on the board will ash

if there is shut down due to priming failure

or dry run. LED will stay on if shutdown is

due to overload. SMC control can be reset

by turning o and on switch. Power need

not be turned o.

5. If power is not turned o to the control,

control will jog macerator pump for few

milliseconds every seven days if non use to

prevent binding of impeller.

A Maintenance Tip!

Loosen stuck impeller by turning motor sha

clockwise from rear with a at-tipped screwdriver.

2

NOTE: This jog feature will function when switch

is in the OFF position.

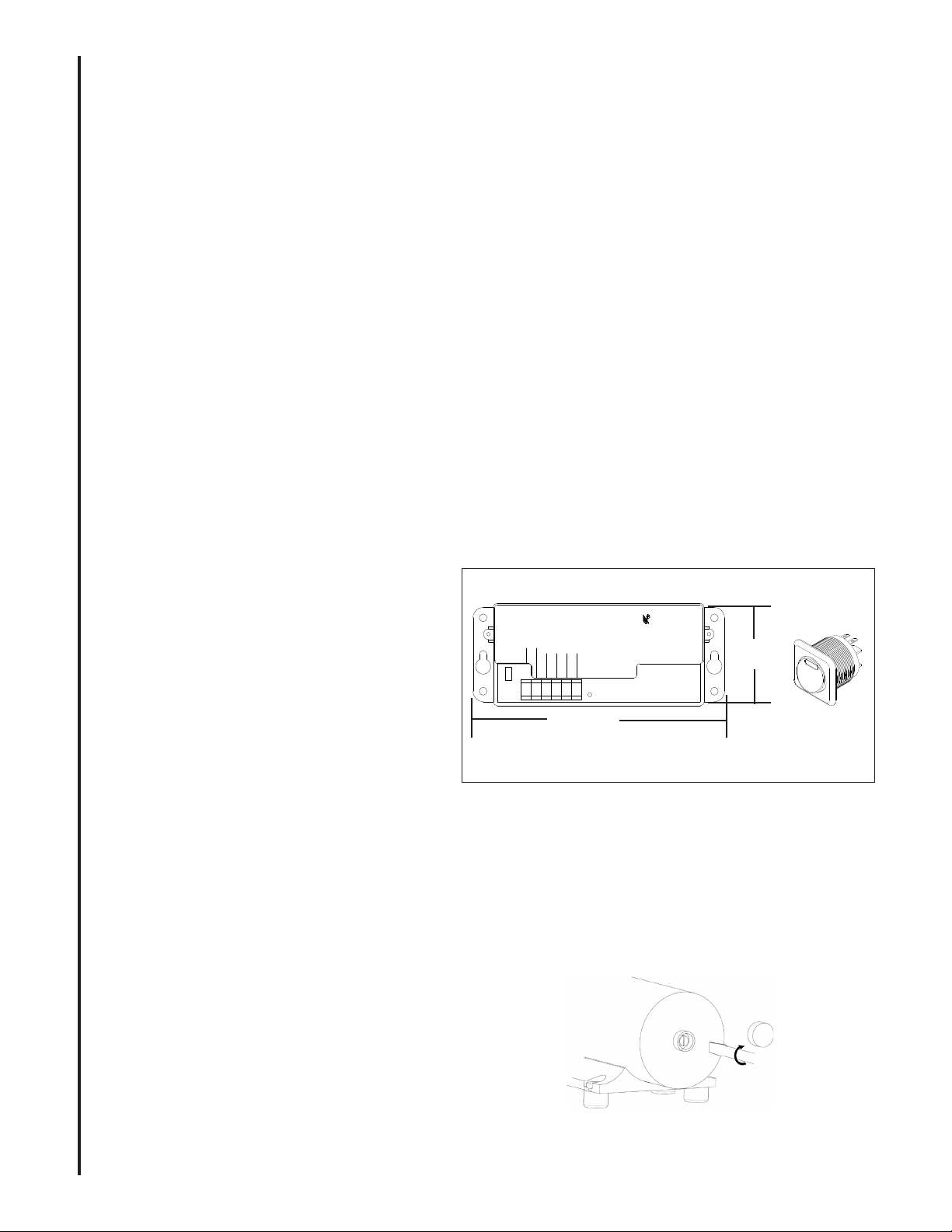

Smart Macerator Control (optional)

Switch dimensions

Fig. 7 pg. 4

Inches [MM]

6 3/16" [157]

1 5/8"

[41]

Depth: 1 5/8" [41]

BATT -

BATT +

RARITAN

SMC

SW-

SW+

PUMP-

PUMP+

Smart Macerator Control