machine as it is aimed.

THROWING DIFFERENT PITCHES Thrown alls will tend to

curve in the direction they are spinning, and the greater the spin, the

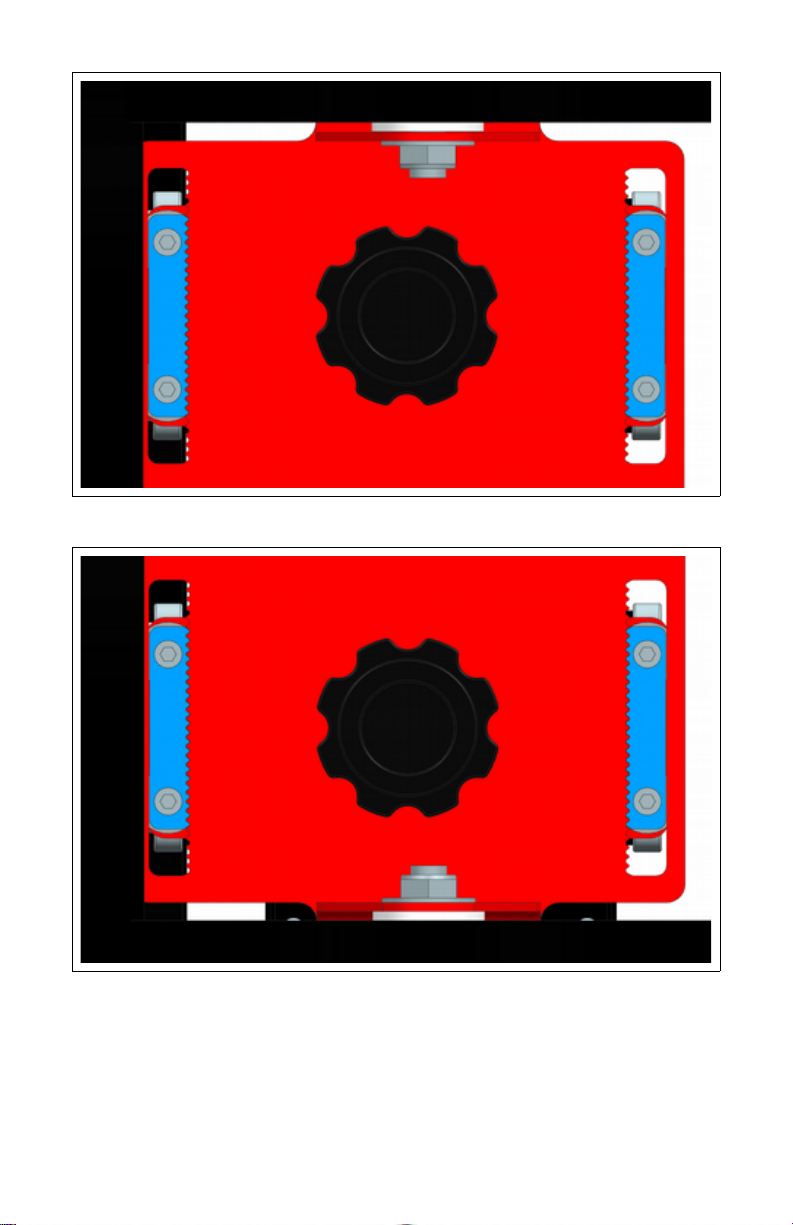

more the curve. Spin is imposed on the all y setting one wheel to turn

faster than the other- the all will spin & curve away from the faster

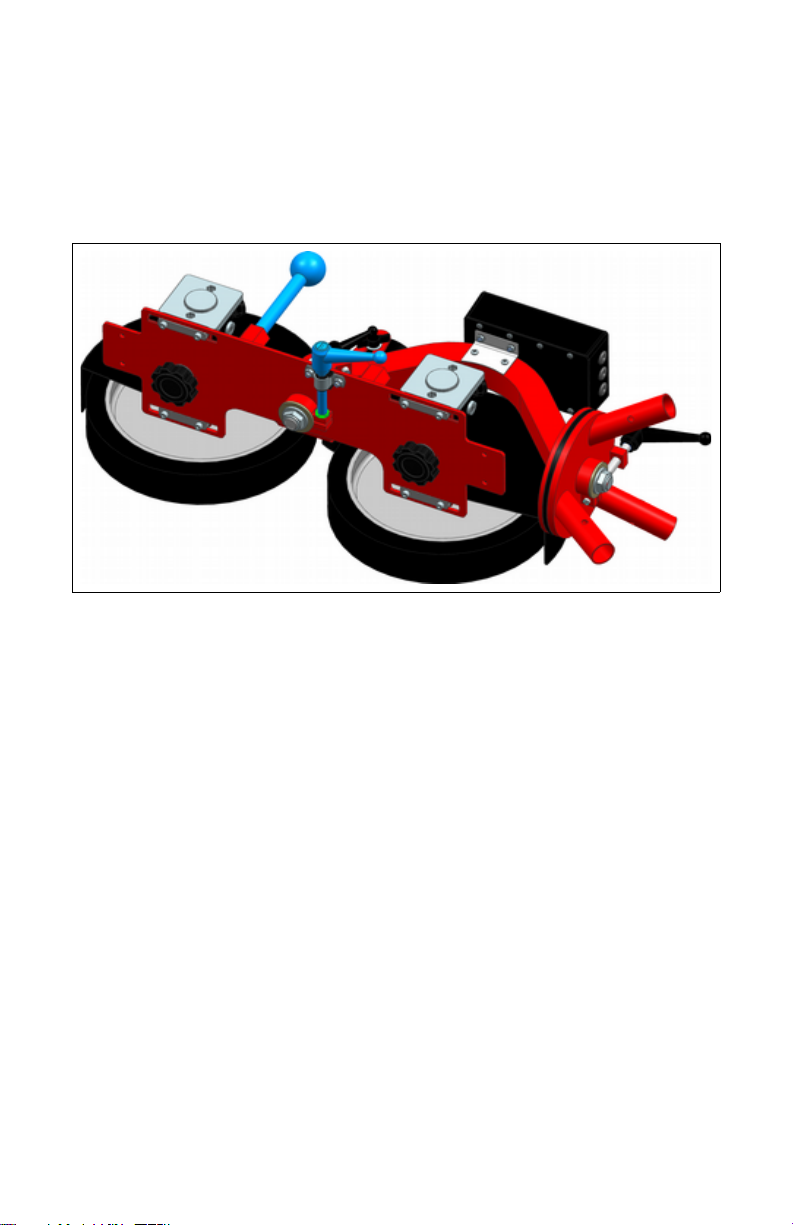

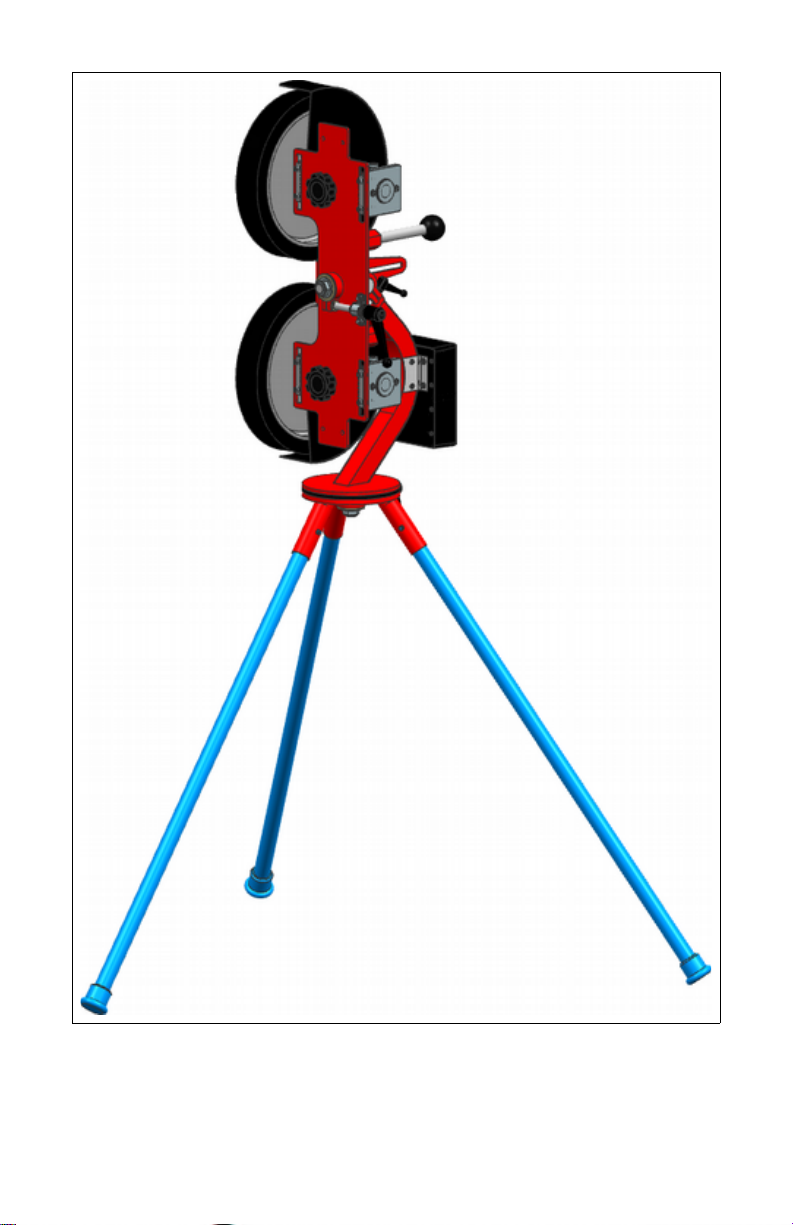

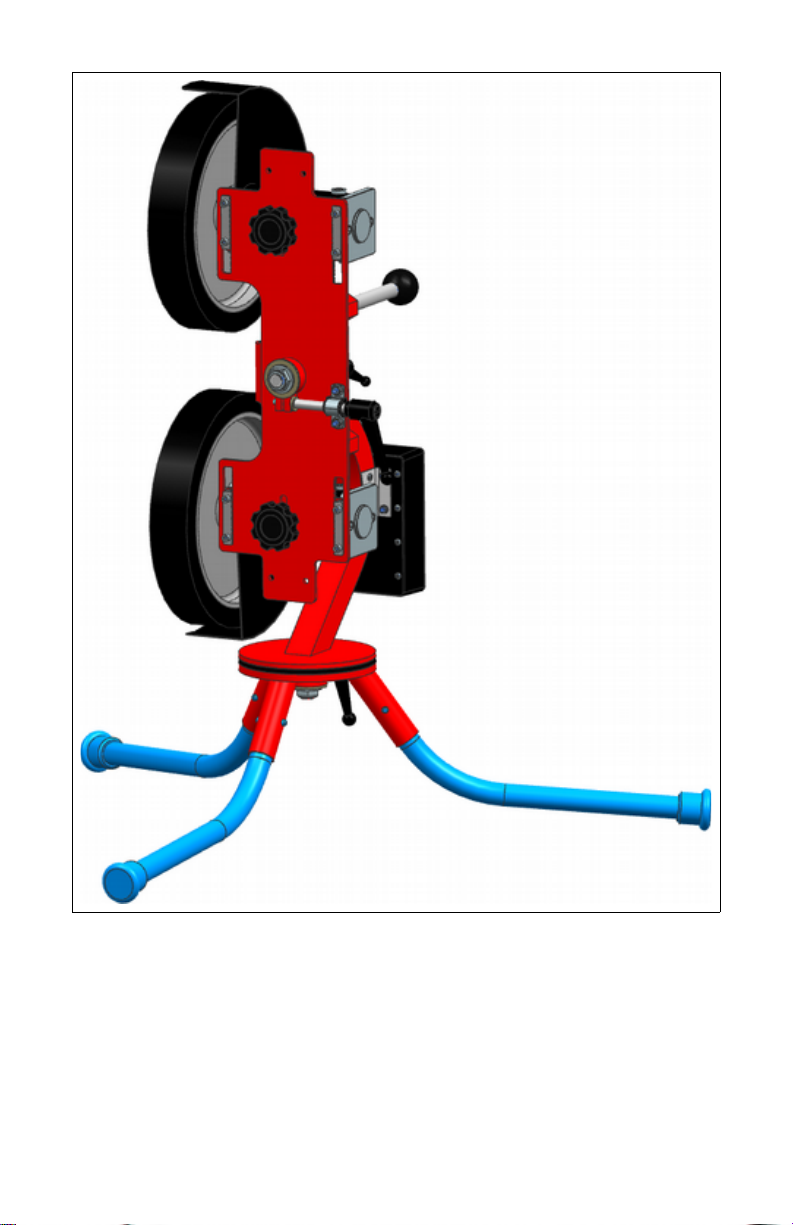

wheel. By rotating the machine on twist angle pin joint, you can set the

curve in any direction. The speed of the all will e the average of the

wheel speed settings. For example, setting one wheel at 60 and the

other at 90 will result in a 75 mph pitch. A laminated chart is included for

guidance, ut it should e considered a starting point.

The most common mistake for new users is to set oth wheels to the

same speed for a fast all. If oth wheels are set to the same speed, the

machine will throw a knuckle all. A fast all has ackspin, so the lower

wheel must e set to a higher speed ( y 20-40 mph) than the top wheel.

ACCURACY The primary factor ehind pitch accuracy is the

consistency of the alls. While you can use many types of alls (real or

dimpled / high or low seam / compressi le or hard) you can not mix them

in one setup and get consistent results. They must e dry and in good

condition. Dimpled machine alls will e more accurate than leather

ase alls, especially after use. Softer alls tend to e more accurate

than harder alls ecause the wheels grip them etter. Lower seams are

etter than high seams (and cause less wheel wear). Rolling the all into

the feeder tu e so that the wheels gra across the seams is etter than

along the seams (4 seam is etter than 2 seam). The more consistent

the alls are, the more consistent the pitches will e.

Another key factor is the distance etween wheels - see otor / Wheel

Position earlier in this manual for a full discussion.

A third factor is the cleanliness of the wheels. After use, especially with

new plastic alls ( oth dimpled and laced), the wheels can accumulate a

residue from the alls. The residue is slick and prevents the wheel from

gra ing the all sufficiently. The wheels can easily e cleaned with

solvent cleaners such as MEK or lacquer thinner. Cheap synthetic

leather ase alls wear quickly and leave excessive residue, so we

recommend against their use. We also recommend not using the Jugs

rand Pearl® ase alls. They seem to e very slick and not as accurate

as standard ase alls, at least with our machines.

If pitches seem to wander during use, check that the pin joints are all

tight. Also check that the entire machine is not moving from recoil. When

used on a hard slick flooring surface such as hardwood or cement, the

machine should e set on a carpet scrap or nonslip mat.

Rawlings Pitching Machines

Rawlings Pitching Machines