5

BEF RE INSTALLATI N

Raypak strongly recommends that this manual be re-

viewed thoroughly before installing your MVB heater.

Please review the General Safety information before

installing the heater. Factory warranty does not apply

to heaters that have been improperly installed or oper-

ated. (Refer to the warranty at the back of this

manual.) Installation and service must be performed

by a qualified installer, service agency or gas supplier.

If, after reviewing this manual, you still have questions

which this manual does not answer, please contact

your local Raypak representative or visit our website at

www.raypak.com.

Thank you for purchasing a Raypak product. We hope

you will be satisfied with the high quality and durability

of our equipment.

Product Receipt

On receipt of your heater it is suggested that you visu-

ally check for external damage to the shipping crate. If

the crate is damaged, make a note to that effect on the

Bill of Lading when signing for the shipment. Next,

remove the heater from the shipping packaging.

Report any damage to the carrier immediately.

On occasion, items are shipped loose. Be sure that

you receive the correct number of packages as indi-

cated on the Bill of Lading.

Claims for shortages and damages must be filed with

the carrier by consignee. Permission to return goods

must be received from the factory prior to shipping.

Goods returned to the factory without an authorized

Returned Goods Receipt number will not be accepted.

All returned goods are subject to a restocking charge.

When ordering parts, you must specify the model and

serial number of the heater. When ordering under war-

ranty conditions, you must also specify the date of

installation.

Purchased parts are subject to replacement only

under the manufacturer’s warranty. ebits for defec-

tive replacement parts will not be accepted. Parts will

be replaced in kind only per Raypak’s standard war-

ranties.

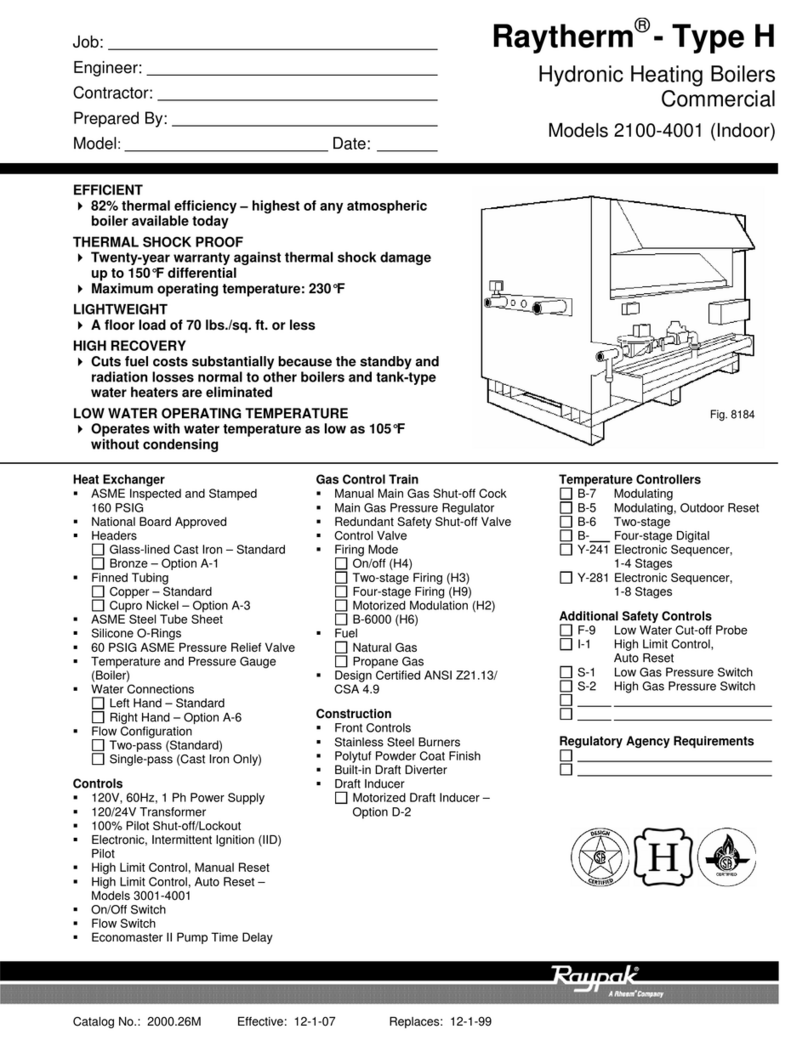

Model Identification

The model identification number and heater serial

number are found on the heater rating plate located on

the upper rear jacket panel of the heater. The model

number will have the form H7-2003 or similar depend-

ing on the heater size and configuration. The letter(s)

in the first group of characters identifies the application

(H = Hydronic Heating, WH = omestic Hot Water

( HW)). The number which follows identifies the firing

mode (7 = electronic modulation). The second group

of characters identifies the size of the heater (three or

four numbers representing the approximate MBTUH

input), and, where applicable, a letter, indicating the

manufacturing series.

Ratings and Certifications

Standards:

• ANSI Z21.13 · CSA 4.9 - latest edition, Gas-Fired

Hot Water Boilers

• CAN 3.1 - latest edition, Industrial and

Commercial Gas-Fired Package Boilers

• ANSI Z21.10.3 · CSA 4.3 - latest edition, Gas Wa-

ter Heaters

• SCAQM Rule 1146.2

• Low-lead content (<.25%) CSA-verified

All Raypak heaters are National Board Approved, and

design-certified and tested by the Canadian Standards

Association (CSA) for the U.S. and Canada. Each

heater is constructed in accordance with Section IV of

the American Society of Mechanical Engineers

(ASME) Heater Pressure Vessel Code and bears the

ASME stamp. This heater also complies with the latest

edition of the ASHRAE 90.1 Standard.

Installations at Elevation

Rated inputs are suitable for up to 4,500 ft elevation

without de-rating. Consult your local representative or

the factory for installations at altitudes over 4,500 ft

above sea level. No hardware changes are required to

the heaters for installations up to 10,000 ft (adjust-

ments may be required).

WARNING: Altering any Raypak pressure vessel

by installing replacement heat exchangers, tube

bundle headers, or any ASME parts not

manufactured and/or approved by Raypak will

instantly void the ASME and CSA ratings of the

vessel and any Raypak warranty on the vessel.

Altering the ASME or CSA ratings of the vessel also

violates national, state, and local approval codes.