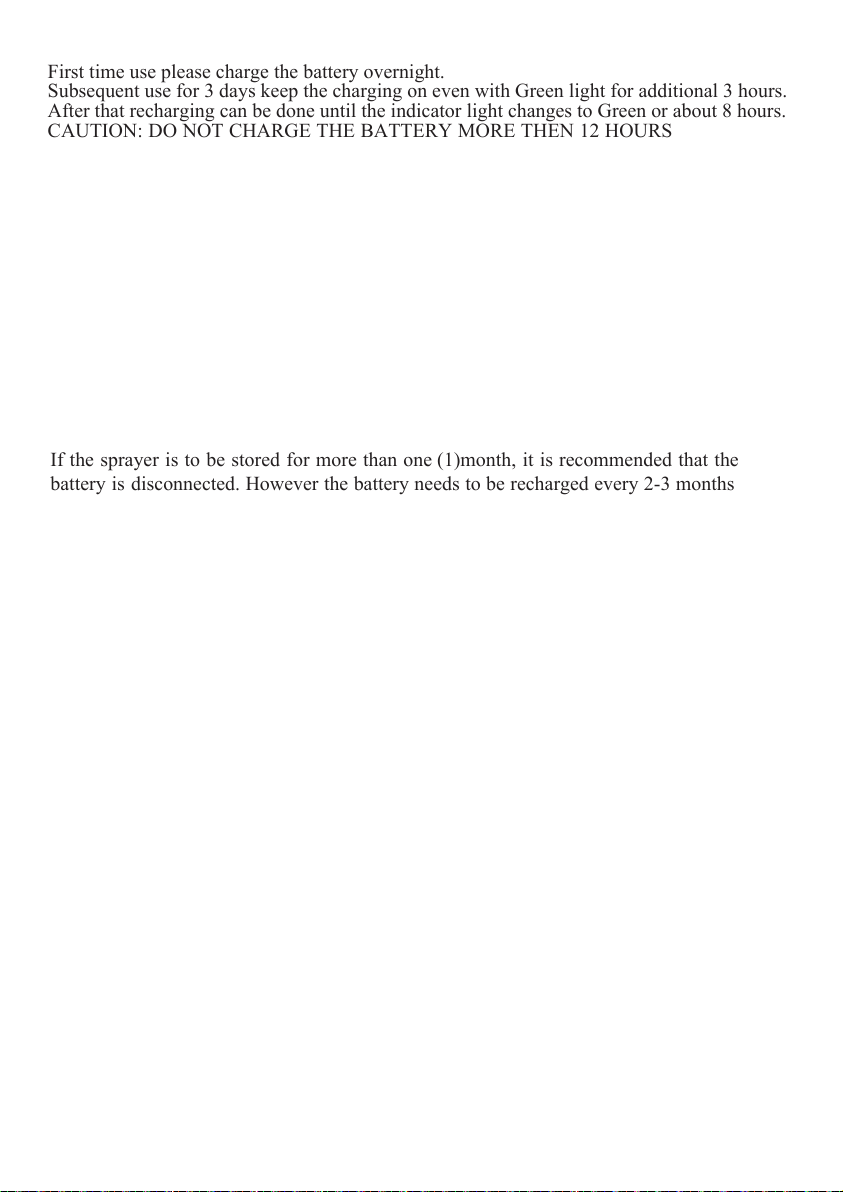

RECHARGING AND MAINTAINING THE BATTERY

First time use please charge the battery overnight.

Subsequent use for 3 days keep the charging on even with Green light for additional 3 hours.

After that recharging can be done until the indicator light changes to Green or about 8 hours.

CAUTION: DO NOT CHARGE THE BATTERY MORE THEN 12 HOURS

i. Connect the battery charger supplied with the sprayer to the 3-pole female

connector on the control panel.

ii. Switch on the sprayer.

iii.

Connect the battery to the main power supply and switch on. The red ‘charging’

and green ‘charged’ indicators will glow.

iv. The battery will be fully charged in approximately 8 hours.

v. After charging remove the charger from the main power supply and return the

switch to

‘OFF’

position to prevent slow battery discharge.

Charger should always be disconnected from the machine, as soon as the battery is

fully charged.

Always store the fully charged battery.

If the sprayer is to be stored for more than one (1)month, it is recommended that the

battery is disconnected. However the battery needs to be recharged every 2-3 months.

With regular cleaning and battery maintenance the NEO DC SPRAYER should give

many years trouble free operation.

Simple maintenance involves regularly cleaning the sprayer both internally and

externally. It is also advised to carry spare CFValves ® (Red 1.5 Bar) and nozzle tips

as these may become worn, blocked or damaged with regular use.

Always ensure switch is in the OFF position when the sprayer is not in use to avoid

battery discharge and for long periods of storage it is advised to disconnect and

remove the 12V sealed lead acid battery.

Always use the correct battery charger as supplied with the sprayer, to maintain

battery condition.

Make sure electrical wires in the sprayer are not damaged with use. Repair/replace as

necessary.

MAINTENANCE

9