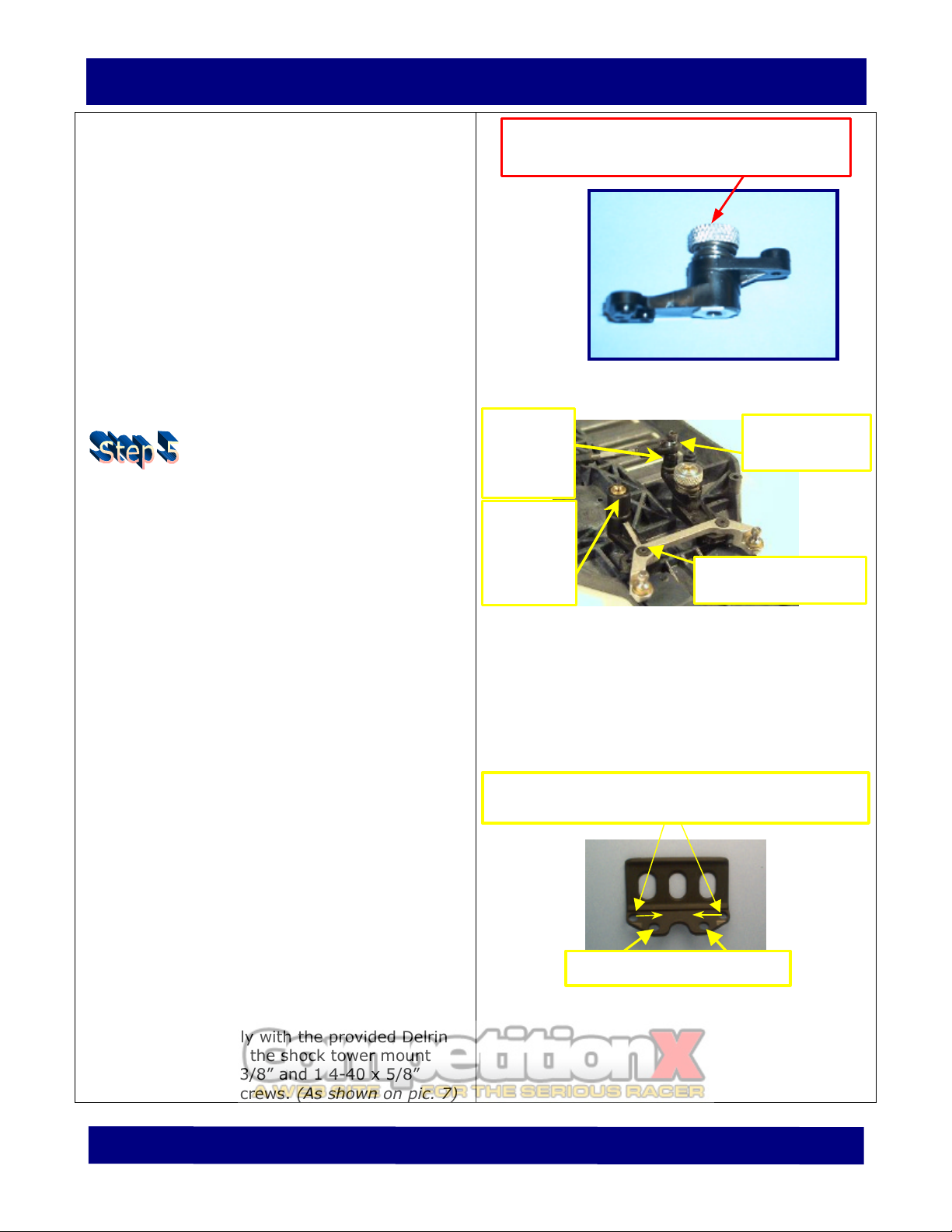

ØMount the Tie Bar part number DC-008

with the provided 4-40 x 3/8” Flat Head

screw over the RH steering crank. Need to

add a #4 washer between tie bar and bell

crank. (As shown in picture 4). Tightened

the screw all the way in, then back off

screw a 1/8 of a turn so that the tie bar

rotates freely.

ØInstall your steering links using the

turnbuckles and ball cups of your choice.

Each link should measure approx. 2.57”

(65 mm) in length from end to end. We

recommend you use a trapped end

cup/eyelet to attach servo link to the bell

crank. (More on that on step 7).

Assemble the Front Suspension:

ØMount the modified pivot blocks (part

number DC-016), starting with the

rearward first using the 2 supplied 4-40 x

½” Flat Head screws. Picture 5.

ØYou need to mount two 1/8” diameter

inner hinge pins. Insert the front A-Arms

(part number DC-013B) into the inner

hinge pin.

ØBe sure to modify and install a Rear

Bumper (Associated part number 3900) in

the front of the chassis as you assemble

the car. This bumper needs to be cut to

clear the gearbox. Also, the forward holes

must be elongated inboard to accept the

front arm mount which has a shorter span

length between the mounting holes. (See

the picture on the right).

ØMount the modified front bumper with the

modified forward front pivot block into the

inner hinge pin. Secure the pivot block

with the 2 provided 4-40 x ½” FH screws.

ØMount the assembled front differential

gearbox, and secure it with the 4 supplied

4-40 x ½” Flat Head screws. (Example

shown on picture 6).

ØInstall the front shock tower mount to the

top of the transmission case. Shim the low

side accordingly with the provided Delrin

spacer. Secure the shock tower mount

with 3 4-40 x 3/8” and 1 4-40 x 5/8”

Socket Head screws. (As shown on pic. 7)

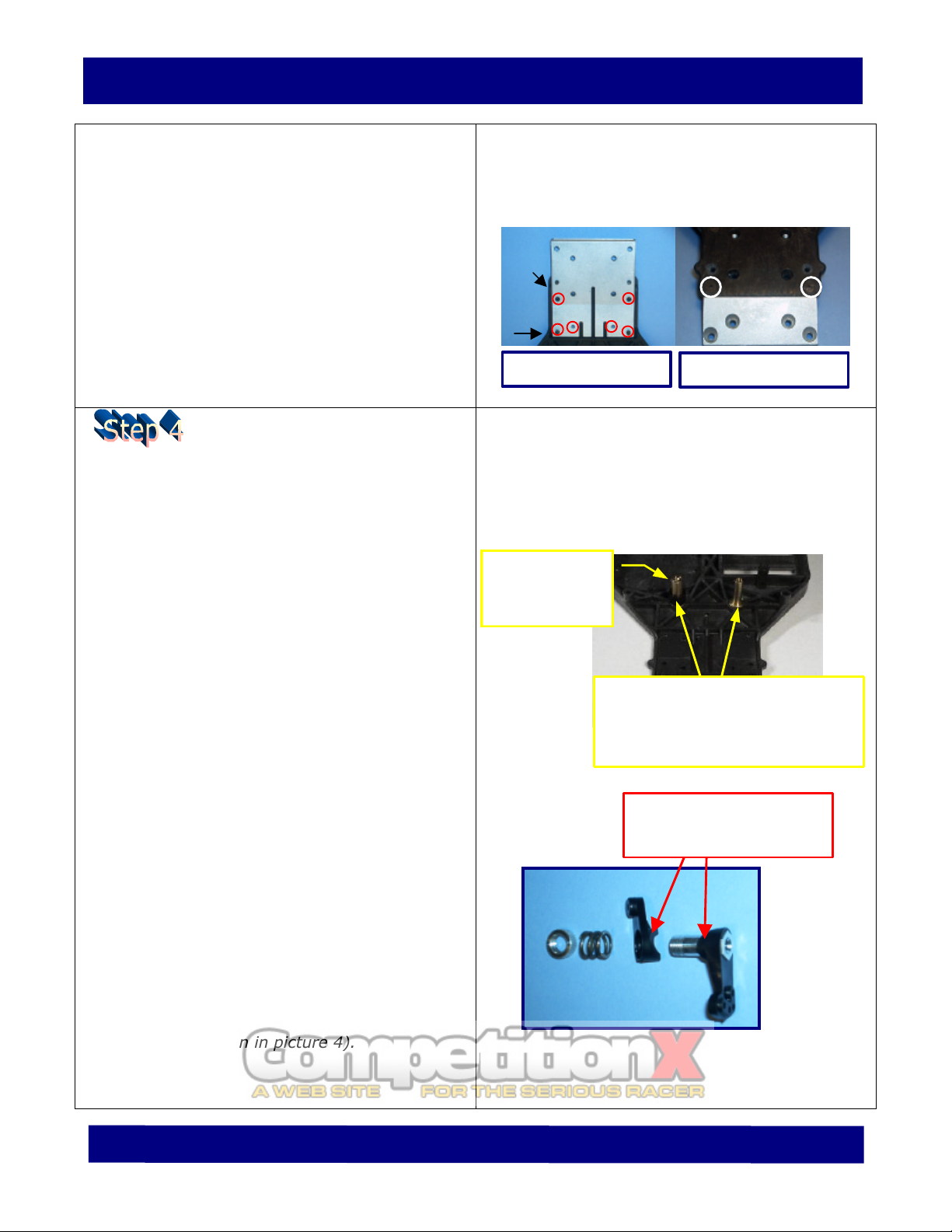

Picture 3

Picture 4: Tie Bar & Steering Bell Crank Installed

Tools required for this step:

Ø1/16” Allen Wrench or Driver

Ø3/32” Allen Wrench or Driver

ØDremmel tool

Elongate the two forward holes in the inboard

direction to fit front modified arm mount.

long spacer

and secure

with 7/8”

long screw.

Install Tie Bar in

forward/inboard hole.

Install black

spacer DC-

007B on large

diameter

post.

end/eyelet cup

Make sure that the upper surface of the

Aluminum nut is below the surface of the