6. Setting the limit switches

Instructions are for right hand installation {left hand installation in Italics}

a) Set unit in manual mode [see 4 g) above] and move door up by hand to the

desired OPEN position.

b) Remove the switch cover . Loosen the three black screws holding the cams

in place (Fig 10). The UP LIMIT cam is the inner-most cam. Move this around

clockwise {anti-clockwise} until it fully engages the UP LIMIT switch.

c) Move the door down by hand to the desired CLOSE position. The DOWN

LIMIT cam is the outer-most cam. Move this anti-clockwise {clockwise} until

it filly engages the DOWN LIMIT switch. Tighten the three black screws.

d) Turn the power on and re-engage the drive gear (pull the green cord).

Up Limit Switch Open limit adjustment

e) Press the 0/S/C button on the uncovered board. The door should

start opening. If the door stopped at the desired OPEN position the

limit adjustment is complete. If not, the UP LIMIT cam will have to be

adjusted as detailed above To open the door more, adjust the cam

clockwise {anit-clockwise}

To open the door less, adjust the cam anti-clockwise

Close limit adjustment

f) Press the 0/S/C button on the board again. The door should start

closing. It the door stopped at the desired CLOSE position the limit

adjustment is complete. If not, the DOWN LIMIT cam will have to be

adjusted as detailed above. To close the door more, adjust the cam

anti-clockwise {clockwise} To close the door less, adjust the cam

clockwise {anti-clockwise}

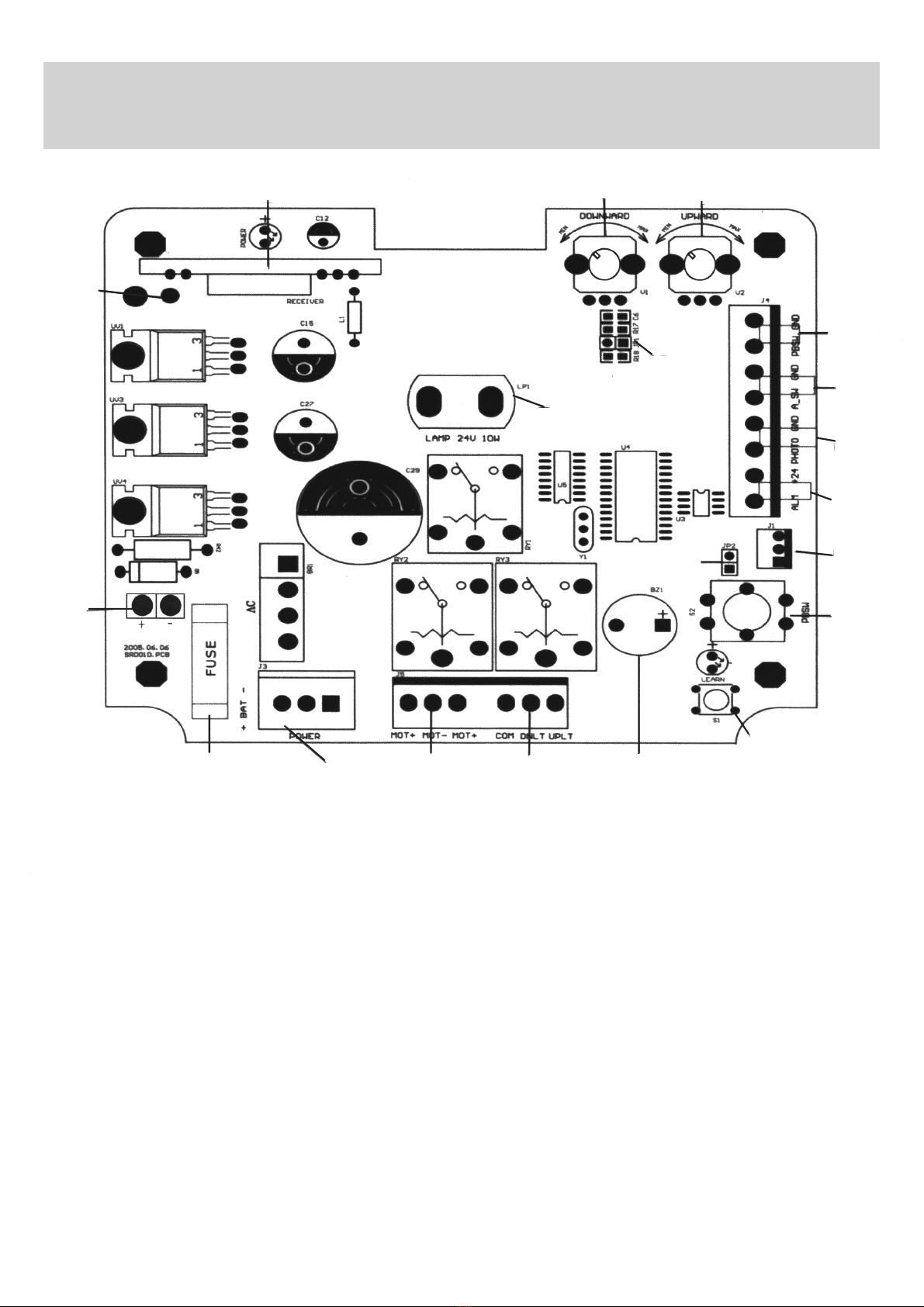

Figure 8

Control Button

Cord

Figure 9

Courtesy Light

Cord

Down Limit Cam

Up Limit Cam

Up Limit Switch

Down Limit Switch

Figure 10

7. Setting force levels for open/close

obstruction detection (Fig 11)

The settings for the open/close obstruction detection force levels are

the most important adjustments in the whole installation procedure.

They are the same for right or left instailation. Failure to set these

levels could result in serious injury or property damage. Once made,

these settings should be tested at regular intervals - once a month

is recommended.

Obstruction detection force level for CLOSE

a) Fully open the door by pressing the 0/S/C button. The door will

stop automatically when the open limit position is reached.

b) Turn the DOWN FORCE knob fully clockwise. Press the 0/S/C

button again - the door should start closing. As the door is closing,

turn the DOWN FORCE knob slowly anti-clockwise until the door

stops momentarily then reverses.

c) Turn the DOWN FORCE knob 10 degrees clockwise. Press the

0/S/C button again to close the door. If the door reverses by itself,

readjust the DOWN FORCE knob a further 5 degrees clockwise. Keep

adjusting in this manner until the door can complete the full closing

cycle.

Obstruction detection force level for OPEN

a) Fully close the door by pressing the 0/S/C button. The door will

stop automatically when the close I limit position is reached.

b) Turn the UP FORCE knob fully clockwise. Press the 0/S/C button

again - the door should start opening. As the door is opening, turn

the UP FORCE knob slowly anti-clockwise until the door stops.

c) Turn the UP FORCE knob 10 degrees clockwise. Press the 0/S/C

button again to open the door. If the door stops by itself, readjust the

UP FORCE knob a further 5 degrees clockwise. Keep adjusting in

this manner until the door can complete the full opening cycle.

Obstruction detection test

The door now has to be tested for response to an obstruction while

it is opening and closing. With the door in the open position, press

the 0/S/C button. The door will start closing. When it reaches about

half way hold the bottom of the door with your hands. If the door

does not readily stop and reverse, the force load setting is too great

and will need adjusting. If the door is unable to reverse, discontinue

use and report the fault to your local distributor. Repeat the test for

the opening cycle.

8. Setting the remote control(s) (Fig 12)

The supplied Remote Control units can be programmed tor any

number of purposes. Although the unit has four buttons, only one is

needed to operate the GarageAce. The same button will open and

close the door. If you have other devices (such as a burglar alarm)

that can program a remote control, use the other buttons for this

purpose.

a) On the CONTROL UNIT board press the LEARN button for 2

seconds. The LEARN LED will turn on.

b) Press the preferred button of REMOTE CONTROL then release

and press again. The LEARN LED will flash about 8 times then turn

off.

c) Press the remote control to test the door open i ng/closing.

d) Repeat these steps for each Remote Control. A maximum of six

remotes can be programmed.

e) It you wish to delete the codes, press and hold the LEARN BUTTON.

The LEARN LED will turn on. Keep holding the LEARN BUTTON for

approx. 8 seconds until the LEARN LED turns off. All stored codes

are deleted. (Recommended if a remote is lost or stolen).

Remote Learn LED

light

Remote

Learn

Button

Figure 12

Downward

Upward

Minimum

Maximum

Figure 11