MAGNETIC WALL PANELS FITTING

INSTRUCTIONS

Please read the following information carefully before

you begin installing your Magnetik wall panels.

GETTING STARTED

Safety equipment required:

• Safety goggles

• Gloves

• Ear protection

• Hard hat

Tools & materials required:

• Pencil

• Spirit level

• Measuring tape

• Jig saw / hand saw / circular saw

• Folding saw horses

• Pair of clamps

• Grab adhesive

• Colour matched sealant

• Slip feathers

• Magnetic wall panels

• Silicone sealant

• Timber

• Screws

• Rawl plugs

• Cloths & solvent

Optional extras

• Extrusions

• Button x (for removable)

• Button x markers

• Dry wipe markers

• Dry wipe cleaning solution

• Microbre cloth for cleaning

PANEL PREPARATION

• Panels should be stored at and left for a minimum

of 48 hours in the environment they are to be installed

in. This is to ensure the panels climatise to their

environment, preventing any unwanted movement

once installed.

• Each panel should be checked to make sure the

protective lm has not been broken and that panels

are not damaged. Any damages to the decorative

face must be reported immediately. Rearo cannot be

held responsible for panels not being checked prior to

installation.

• Check through the lists to the left to make sure you

have everything you need to install the wall panels.

WALL PREPARATION

• Rearo MagnetiK wall panels can be installed onto

plasterboard, timber frame, metal frame and tiles.

• It is essential that walls are completely dry before

installing the panels and any source of dampness is

treated.

• There is no need to make good the surface to be

covered.

• Wherever possible, remove existing wall coverings

such as wall paper and fabrics.

• If installing on top of tiles, make sure the tiles are

scored with a sharp knife and sanded to allow for an

abrasive surface for the adhesive to effectively bond

to.

• If installing onto a timber frame, you can use panel

adhesive as well as button x clips to ensure panels

are secured properly in place.

• We do not recommend xing panels to masonry or

cement surfaces.

CALCULATING PANEL QUANTITIES

• Panels should not be exposed to moisture or water,

direct sunlight, hot air currents or direct exposure to

heat exceeding 70ºC.

To estimate the total number of panels required:

• Measure the total linear metrage of the walls.

• Divide this by 1.2m (width of the panel).

• Round up to the nearest whole number for total panel

quantity.

This method utilises all panel offcuts, so take care when

cutting panels as the offcut will be next to be installed.

CUTTING & FITTING

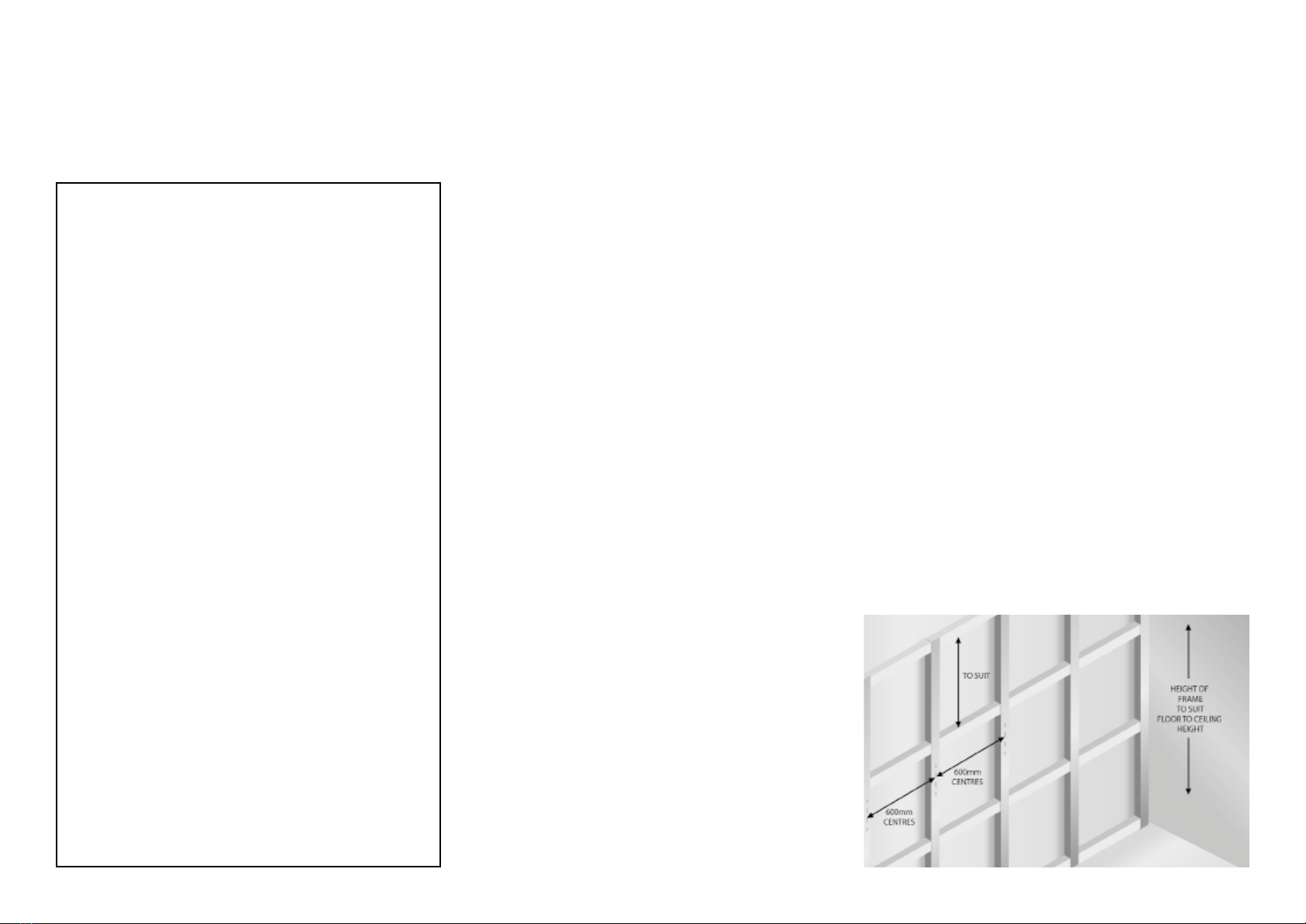

Fitting to a Timber Frame

• The timber frame should be installed with vertical

timbers at 600mm centres to provide xing points for

clips and adhesives, as well as horizontal timbers at

600mm - 900mm centres, packed out to a true, at

and plumb surface. (see g.1)

Fig. 1