v

Read this manual completely before operating: follow all safety instructions.

Skin absorption rates

in relation to forearm (1.0)

The skin on various body parts does not absorb pesticides at the same rate.

The figure, right, illustrates skin absorption rates based on a numerical scale in

which the value of 1 for the forearm represents the lowest dermal absorption rate.

That value forms the basis for the assignment of values to the other body parts.

If concentrated liquid chemical is spilled on your clothing (not including rubber

gloves, boots, or aprons) immediately remove the clothing and throw away. Undi-

luted chemicals cannot be cleaned from clothing. Dispose of contaminated clothing

as required by local regulations.

Always treat clothes worn when using agricultural chemicals as contaminated. Keep

them separate from your other clothes or the family washload.

Contact your local extension service for instructions for cleaning work clothes

contaminated by chemical handling. Most state agricultural universities and farm

bureaus have detailed instructions for the decontamination of work clothes.

Line dry your work clothes to avoid contaminating your dryer.

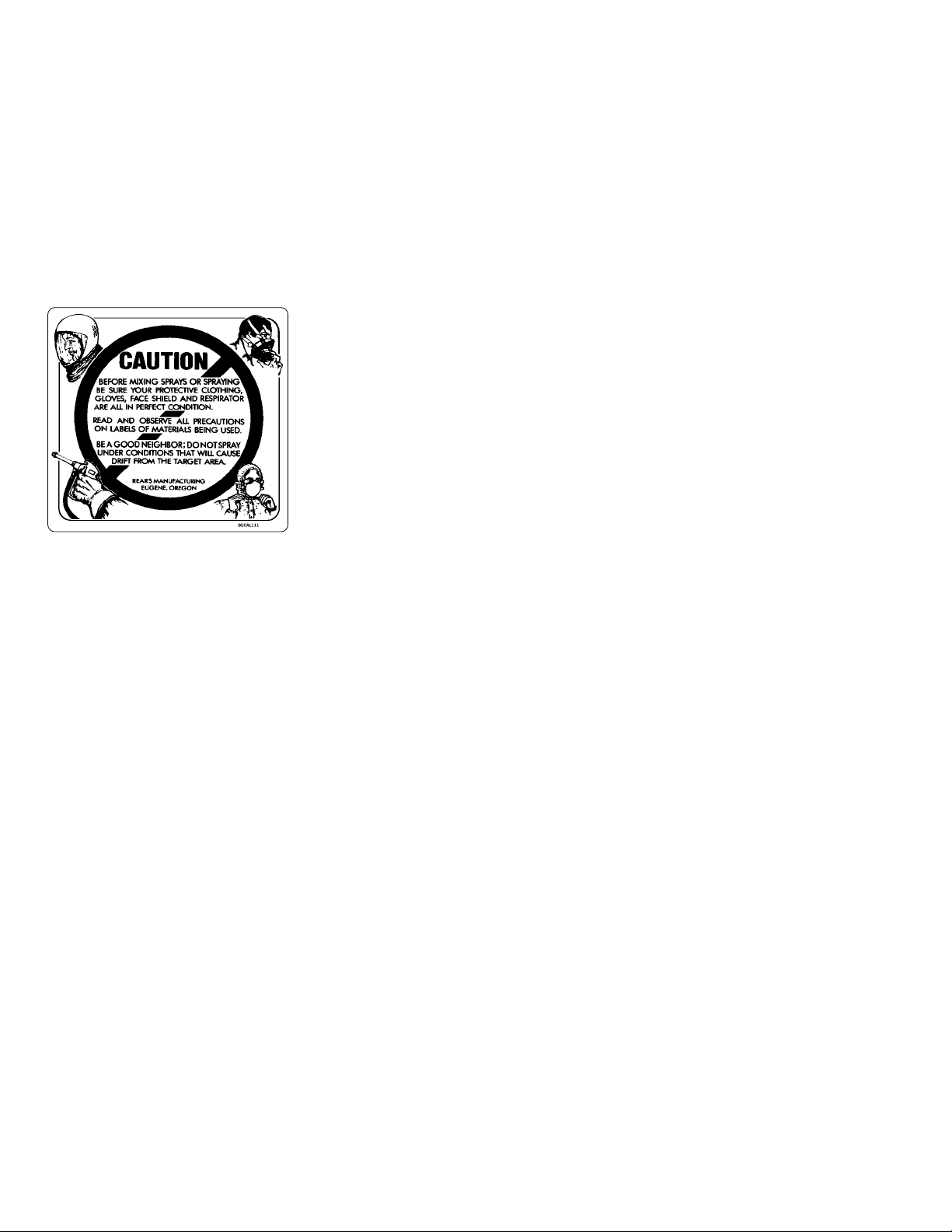

Chemical resistant gloves make a big difference BUT don’t rub contaminated gloves

on your skin. A good safety practice before eating, drinking, smoking, or using

the bathroom: rinse your gloves thoroughly BEFORE removing them then take

off your gloves and wash your hands.

Trained personnel should thoroughly clean the inside and outside of mixing and ap-

plication equipment immediately after use. Follow all chemical handling directions

supplied by the manufacturer and wear recommended safety equipment. Clean and

neutralize the pump system, spray manifolds, and spray tank as recommended by

the chemical manufacturer. Cleaning between implement uses will reduce corrosion,

extend pump life, and keep your chemical tools from reacting with residual incom-

patible mixes.

Always follow the chemical manufacturer’s instructions and environmental regula-

tions when disposing of chemical waste and empty chemical containers.

The information included in this Chemical

Safety section was compiled from the following

government and community education programs:

Oregon Occupational Safety & Health

Alliance for a Clean Rural Environment

University of Missouri Outreach & Extension

California Dept. of Pesticide Regulation

All listed source organizations have more de-

tailed information on the internet.