FIRST TIME COMMISSIONING PROCEDURE

DO NOT plug in the heat pump

or connect the controller

communication cable yet

IMPORTANT NOTE

STEP 1

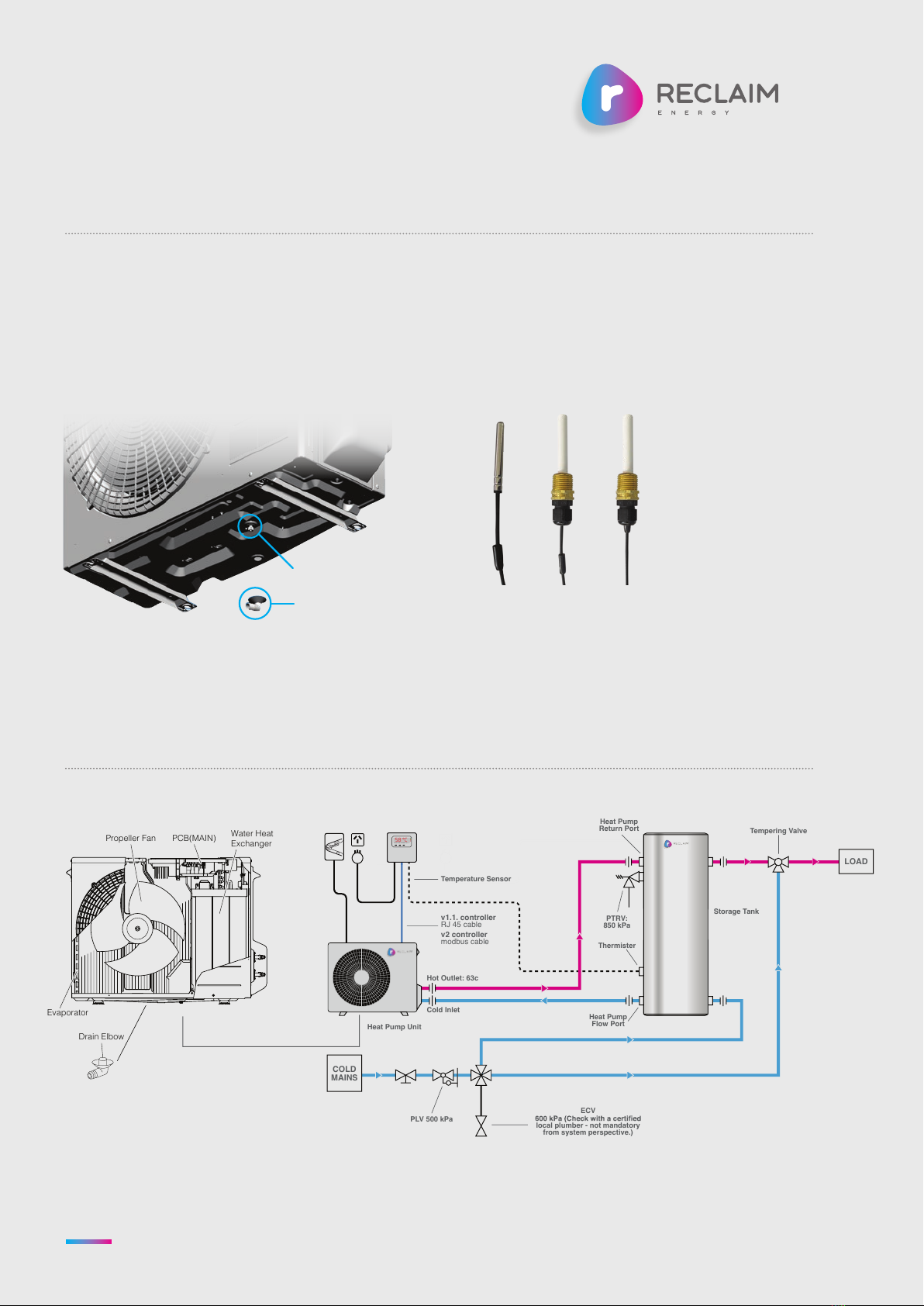

• Ensure the system plumbing comply

with the diagram provided here.

STEP 2

• Ensure the system wiring comply

with the diagram here. Make spacial

attention to sensor insertion on the

lower level of the tank and the

sensor must be fully in.

STEP 3

• Ensure you have filled the tank and

purged all the air by opening a tap

inside the house. The tank will be

purged when water runs freely

from the tap.

• Turn tap off.

• The cylinder has now been purged.

STEP 4

• Purge the circulating pump by

losening the brass 8mm nut on

the underside of the heat pump

untill water runs freely then

tighten again.

• The circulating pump has

now been purged.

STEP 5

Commission the controller

• select correct time of day

• select the desirable operational

mode (i.e. options 1-6)

• power up the controller and

connect the communication

cable to heat pump

STEP 6

• Initiate auto purge and system

start up.

• Ensure the system controller

is turned on and the time is

displayed.

• Ensure the heat pump isolator

is in the on position and power

is on to heat pump unit.

• On the controller, push and hold

the “menu” or “OK” button (i.e.

“menu” for V1 controller and “OK”

for V2 controller) until the word

“purge” is displayed and flashing

(approx 5 seconds).

• Now let go of the button.

• In about 4 seconds you should

hear the on-board circulating

pump come on.

SYSTEM STARTUP SEQUENCE

The system is now starting up and

will go through the following

sequence:

1The system will run a 5 minute

purge that pushes any air within

the heat pump unit into the tank.

Note the unit fan won’t be turning

at this point).

2After this 5 minute period the

pump will stop and the fan will

turn slowly. The system will not

be heating up until the until can

maintain a consistent 63°C (this

may take up to 4 minutes).

3The unit fan comes on properly

and the circulating pump starts to

circulate that constant 63°C water

through the tank.

Due to the smart top down heat

return system your customer

will have 50L of hot water within

20 minutes and a full tank in

about 3 hours.

After 15 minutes touch the heat

pump return connection to the

tank and ensure it is hot to touch,

if you feel good heat here you are

done and can comfortably leave

knowing you have completed

the install successfully.

HOW TO USE V1.1 OR V2

CONTROLLERS WITH

THE V2 HEAT PUMP

The V2 heat pump default mode is

with V1.1 controller. As such, if V1.1.

controller is received, simply the

controller can be connected to RJ 45

port on the PCB display of heat pump

and the general commissioning

process to be followed.

If V2 controller is received, the

following steps on the heat pump

is required before V2 controller

can be used:

STEP 1

Connection of correct cable to the

right terminal

• V1.1 controller: RJ 45 terminal

block to be used

• V2 controller: Modbus terminal

block to be used

STEP 2

Change the mode on the PCB display

from 1 to 2 using PCB display

Change the value of “r1” to “2” as

follows:

1. Press and hold UP(▲) and

DOWN(▼) buttons.

2. The value displayed is “r1” & “1”

3. Change the value of “r1” to “2”

by pressing the RIGHT( ) or

LEFT( ) button.

4. Press and hold UP(▲) and

DOWN(▼) button to complete the

setting when display returns to its

original display (i.e. blank display).

5. To check if “r1” & “2” is

established, try step 1 one

additional time and then go to step

4 to exit.

Reclaim Energy |Quick Start/Install Manual – v2.0

8