Rectifier RT9- 24V User manual

Installation, Operation and

Technical Manual

RT9- 24V and MCSU-4 Rack Power System

Document: 158-1872-01

Date: 19 February 2014

© Rectifier Technologies Pacific Pty Ltd

ACN 058 107 707

Installation, Operation and Technical Manual Rectifier Technologies

158-1872-01 ii 19-Feb-14

Table of Contents

1. General Warnings ......................................................................................................1

2. Summary of Programmed System Parameters .......................................................2

3. Configuration..............................................................................................................5

3.1 System Description................................................................................................5

3.1.1 General Description........................................................................................5

3.1.2 Rectifier Specific Configurations.....................................................................7

4. Installation..................................................................................................................8

4.1 System Installation ................................................................................................8

4.1.1 Racks .............................................................................................................8

4.1.2 Magazines......................................................................................................8

4.1.3 Lightning and Transient Suppression.............................................................8

4.1.4 Cabling, Auxiliary Equipment and Circuit Breakers........................................9

4.2 Rectifier Installation and Removal.......................................................................11

4.2.1 To Remove a Rectifier from the Magazine...................................................11

4.2.2 Inserting a Rectifier into the Magazine .........................................................11

4.3 MUIB - Mini User Interface Board........................................................................12

4.3.1 MUIB Connections .......................................................................................12

4.4 MUIB2 - MCSU-4 User Interface Board (type2)...................................................16

4.4.1 System setup requirement............................................................................16

4.4.2 Main features of MUIB2................................................................................16

4.4.3 MUIB2 Connections .....................................................................................16

4.4.4 Fuses............................................................................................................18

4.5 MUIB3 – Systems with Earth Leakage Detection................................................21

4.5.1 System setup requirement............................................................................21

4.5.2 Main features of MUIB3................................................................................21

4.5.3 MUIB3 Connections .....................................................................................21

4.6 Single Phase AC Monitoring Module – MMIB4....................................................26

4.7 Three Phase AC Monitoring Module – MMIB2....................................................26

4.8 SMM - Site Monitor Module.................................................................................28

4.8.1 Electrical Specification .................................................................................28

4.8.2 Physical Specification...................................................................................28

4.8.3 Installation....................................................................................................29

4.8.4 System Set-up..............................................................................................29

4.8.5 Site Monitor Settings ....................................................................................31

Installation, Operation and Technical Manual Rectifier Technologies

158-1872-01 iii 19-Feb-14

4.9 Battery Cell Monitor (BCM)..................................................................................32

4.9.1 Main Features of the BCM............................................................................32

4.9.2 BCM Specifications......................................................................................33

4.9.3 Preparing the battery for connection to the BCM..........................................33

4.9.4 Installing the board.......................................................................................34

4.9.5 Dip-Switch Selection of Cell Voltages ..........................................................34

4.9.6 Battery Cell Lead Connection to the BCM board..........................................35

5. Remote Communication Interfaces........................................................................43

5.1 Ethernet (TCP/IP) and SNMP Interface (WebCSU)............................................43

5.2 RS232 Interface (MCSP).....................................................................................43

5.3 RS485 Interface (MCMD)....................................................................................43

5.4 Integrated Packet Modem (Smart Modem)..........................................................43

6. Operation..................................................................................................................45

Summary of MCSU-4 front panel controls....................................................................45

6.1 MCSU-4 Components .........................................................................................46

6.1.1 Alpha-numeric Display..................................................................................46

6.1.2 Front Panel Pushbuttons..............................................................................46

6.1.3 Status Indicating LEDs (MCSU-4)................................................................47

6.2 Operating the MCSU-4........................................................................................47

6.2.1 Password security ........................................................................................47

6.2.2 Test Mode ....................................................................................................48

6.2.3 Entering and moving through different Menus..............................................48

6.2.4 When an alarm condition exists....................................................................48

6.3 MCSU-4 Alarms...................................................................................................49

6.4 User programmable relay functions.....................................................................50

6.5 Mapping of loaded SMRs ....................................................................................51

6.6 MCSU-4 Base Menu Screens..............................................................................51

6.6.1 Single Phase AC Monitoring Screens ..........................................................51

6.6.2 Three Phase AC Monitoring Screens...........................................................52

6.6.3 Base Menu Programmable Parameters .......................................................53

6.6.4 Auxiliary Function Selection & Parameters...................................................57

6.7 SMR Menu Screens ............................................................................................61

6.7.1 SMR Menu Programmable Parameters .......................................................62

6.7.2 SMR Menu Sleep Mode ...............................................................................63

6.8 Battery Parameter Menu Screens .......................................................................64

6.9 Battery Discharge Test........................................................................................68

6.9.1 Results of last Battery Discharge Test - (Last BDT).....................................70

Installation, Operation and Technical Manual Rectifier Technologies

158-1872-01 iv 19-Feb-14

6.10 Alarms Log Screens.........................................................................................71

6.11 Battery Cell Monitor Setup...............................................................................71

6.11.1 Relationship between “BCM Batteries” and “Num Batteries”........................72

6.11.2 Frequency of measurement..........................................................................72

6.11.3 Battery Cell Measurements..........................................................................72

6.12 Earth Leakage Detector - MUIB3 and MUIB5 only...........................................73

7. Commissioning ........................................................................................................74

7.1 Indicators on the Rectifier Front Panel ................................................................74

7.2 System Parameter Ranges .................................................................................74

7.2.1 RT9 SMR Parameters..................................................................................74

7.3 System Commissioning.......................................................................................74

7.3.1 Commissioning Procedure ...........................................................................75

8. Maintenance .............................................................................................................76

8.1 Warnings and precautions...................................................................................76

8.2 SMR Maintenance...............................................................................................76

8.2.1 Current Sharing............................................................................................76

8.2.2 Integrity of Electrical Connections ................................................................76

8.2.3 Fan Filter Maintenance.................................................................................76

9. Fault Finding and Replacement Procedures .........................................................78

9.1 System Fault Finding Procedures........................................................................78

9.2 MCSU-4 Fault Finding and Repair Procedures ...................................................81

9.2.1 Replacing MCSU-4.......................................................................................82

Installation, Operation and Technical Manual Rectifier Technologies

158-1872-01 119-Feb-14

1. General Warnings

1. This equipment has been designed to be used only in restricted access areas.

2. This equipment must only be serviced by authorised and qualified service personnel.

3. Operators should not attempt to repair faulty units. There are no operator serviceable

parts inside. All fuses are only replaced as part of a repair procedure in a repair

facility by authorised personnel and not as a maintenance procedure on site.

4. The rectifier must be mounted in a rack that satisfies requirements for electrical

enclosures and fire enclosures according to IEC60950 or equivalent standard. The back

of the rectifier magazine must not be accessible to operators under any condition.

Suitable access barriers above the topmost and below the bottom-most magazine must

prevent operator access to the back of the magazine.

5. The top and bottom of the rectifier must not be accessible during operation. The front of

the rack must be closed off to prevent operator access to the top and bottom of the

rectifier. Any openings in the front of the rack above or below the rectifiers must be

closed off by equipment, blanking panels or ventilation panels.

6. The rectifiers must be used with sufficient ventilation. After mounting, the air flow paths

into and out of the rectifier must be unrestricted. Allow adequate flow for hot exit air at

the top.

7. The input disconnect device is the rectifier backplane connector. The rectifier is live at

all times when the rectifier backplane connector is connected.

8. Take care when removing the rectifier as it may be too hot to touch the metal casing,

especially if the ambient temperature is high and the unit has been operating at

maximum load. When removing, pull the unit halfway out of the magazine and let cool

for 2-3 minutes before handling.

Installation, Operation and Technical Manual Rectifier Technologies

158-1872-01 219-Feb-14

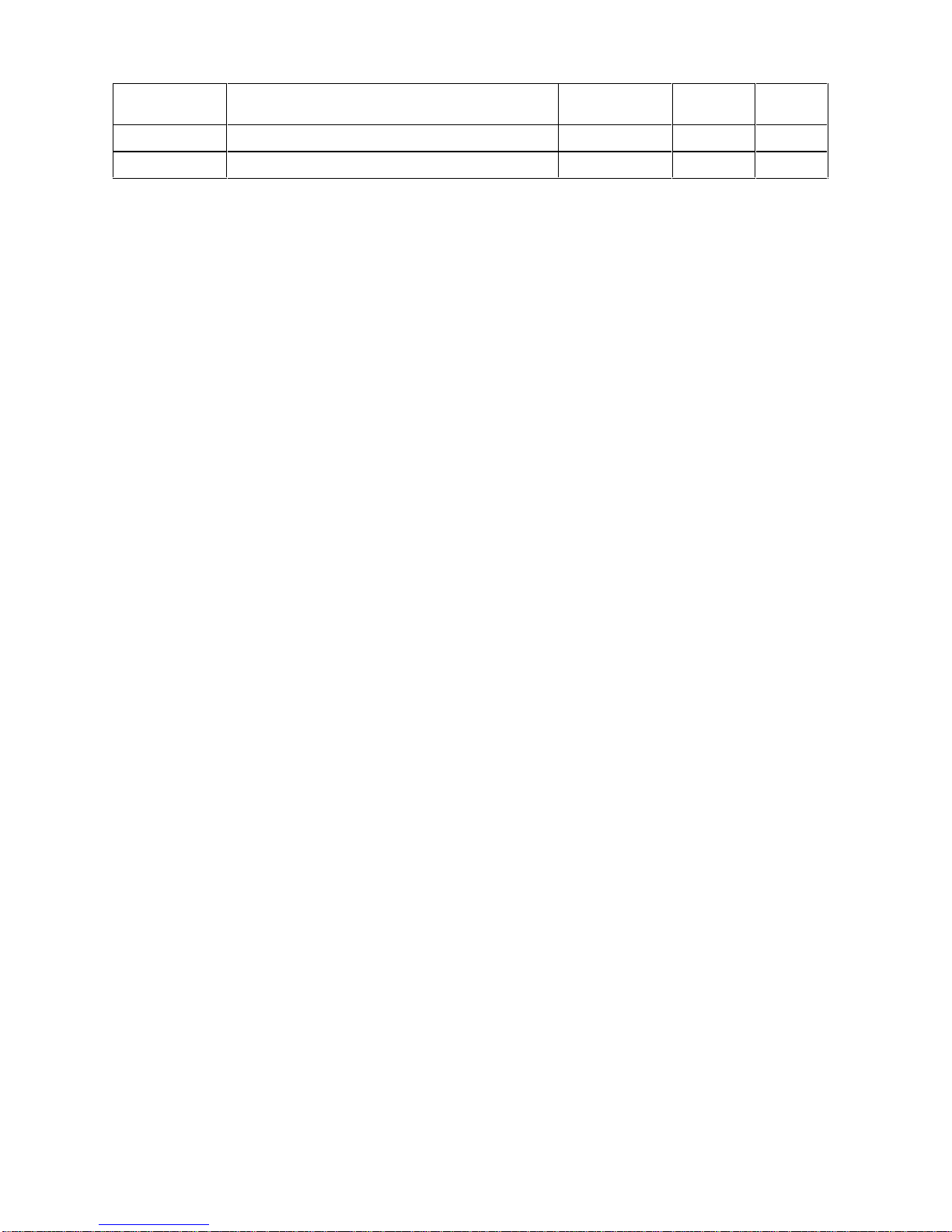

2. Summary of Programmed System Parameters

Parameter

Description

Range

Default

Value

Actual

Value

Base (System) Menu

Amb Tmp Alm

Ambient temperature alarm level

30-99°C

55°C

Volts Hi

System output volts high threshold

26-33V

28.7V

Volts Low

System Output volts low threshold

20-27V

22.5V

System:

Select system duty type

UPS/Standby

UPS

No. of SMRs

Set number of SMRs in the system

0-225

1

Num Batteries

Number of Battery strings installed

1-4 1)

1

FS Batt I

Battery current transducer full scale rating

10-30000A

100A

CSU #

CSU Access code (up to 7 digits)

0-9999999

0000000

Date / Time

Current system date and time

Auxiliary Units Submenu

AC 1-ph Menu

(After enabling AC 1-ph Monitor)

1ph ACV Hi

AC supply high voltage alarm

220-315V

260V

1ph ACV Lo

AC supply low voltage alarm

140-270V

200V

1ph ACF Hi

Frequency high alarm

50-65Hz

55Hz

1ph ACF Lo

Frequency low alarm

40-60Hz

45Hz

1ph ACI FS

AC supply current transducer full scale rating

10-500A

100A

AC 3-ph Menu

(After enabling 3-ph AC Monitor)

3ph ACV Hi

AC supply high voltage alarm

220-315V

260V

3ph ACV Lo

AC supply low voltage alarm

140-270V

200V

3ph ACF Hi

Frequency high alarm

50-65Hz

55Hz

3ph ACF Lo

Frequency low alarm

40-60Hz

45Hz

3ph ACI FS

AC supply current transducer full scale rating

10-500A

100A

Battery Monitor Menu

(After enabling Battery Monitor)

Bat Config

Battery Monoblock size x number

(see BCM section of manual for more detail)

Various

configurat’ns

12 cells

BCM Batteries

Number of battery banks to be monitored

1-4

1

Vhi Cell

Cell high voltage alarm

2.0-16.0V

2.5V

Vlow Cell

Cell low voltage alarm

1.0-12.0V

1.8V

+dVc Cell

Cell positive deviation alarm

5-99%

10%

-dVc Cell

Cell negative deviation alarm

5-99%

10%

Site Monitor Menu

If included in the system refer to Site Monitor documentation.

SMR Menu 2)

SMR Float

Operating float voltage 3)

27.5V

SMR Equalise

Operating equalisation voltage 3)

28.5V

SMR V High

SMR voltage high alarm

26-32.5V

28.0V

Installation, Operation and Technical Manual Rectifier Technologies

158-1872-01 319-Feb-14

Parameter

Description

Range

Default

Value

Actual

Value

SMR V Low

SMR voltage low alarm

22-27V

24.0V

SMR HVSD

SMR high volts shut down

27-33V

28.7V 4)

SMR I Limit

SMR current limit

5-130A

15A 4)

SMR Power

Max

Max power for SMR

0-8000

1400

Sleep Mode

SMR Sleep Mode Enable.

On/Off

Off

Sleep Min

SMR

SMR Sleep Mode Minimum rectifiers that must

be online.

0 to Number

SMR defined

in the system

1

Sleep Rotation

SMR Sleep Mode rectifier rotation value (in

Days).

1 to 365, 0 =

Off – no

rotation

7 days

Battery Menu

B Dis Al

Battery discharge alarm threshold

22-26V

23.0V

Disch I Diff

Battery string discharge current difference alarm

5-99A

20A

Batt T Alrm

Battery Temperature alarm threshold

30 to 90°C

40°C

Bat Rated

Ampere-hour rating of batteries

20 to 9999AH

500Ah

BTC

Battery Temperature Coefficient

0-6mV/°C/cell

0mV(Off)

Number Cells

Number of chemical cells in battery string

11-23

12

BILim Vb<Vdd

Battery charging current limit for Vb < Vdd

5-999A

50A

Vdd Level

Battery deep discharge voltage threshold

20-23.5V

22.5V

BILim Vb<Vf1

Battery charging current limit between Vdd & Vfl

5-999A

50A

Sys Float

System float voltage (Vfl)

24-29V

27.0V

Sys Drop

System voltage drop

0.0-1.0V

0.5V

Equalisation

Enable/Disable EQ function

On/Off

Off

BILim Vb>Vf1

Battery charging current limit in equalise Vb > Vfl

5-999A

50A

Sys Equal

System equalise voltage (Veq)

25-30.5V 5)

28.0V

V Start Eq

Enable/disable discharge voltage initiation of Eq

On/Off

Off

V Eq trig

Discharge voltage threshold for Eq. charging

22-25V

24.0V

Q Start Eq

Enable/disable battery charge depletion trigger

On/Off

Off

Qdis Trig

Charge depletion threshold for Eq. charging

5-999AH

15AH

EQ End Current

Equalisation termination for Ibat < EQ End

1-2000A

5A

EQ Duration

Maximum duration of Equalisation charging

3-48 Hr

20 Hr

EQ Period

Time between periodic Equalisation charging

0-52 Wk

12 Wk

LVDS Trip

Battery voltage below which will open LVDS

20-24V

22.0V

BDT Per

Period between consecutive discharge tests

0-365 days

30 days

BDT Time

Time of day to begin BDT (hr:min)

00:00-23:59

02:00

BDT Dur

Maximum duration of BDT

5-1440min

180min

BDT Curr

Discharge test current

0-5000A

50A

BDT End V

Battery voltage limit to terminate BDT

18-24V

22.0V

Installation, Operation and Technical Manual Rectifier Technologies

158-1872-01 419-Feb-14

Parameter

Description

Range

Default

Value

Actual

Value

BDT End Q

Battery capacity limit to terminate BDT

25-9995AH

300AH

Temp Sen Alm

Enable/Disable Temp. Sensor failure alarm

On/Off

Off

1) Maximum of 4 batteries with MUIB2, maximumof 2 batteries with other interfaces.

2) See SMR section for internal parameters.

3) Not directly adjustable – see explanation in MCSU-4 section.

4) Will be automatically programmed to SMR internal setting once connected in the system.

Installation, Operation and Technical Manual Rectifier Technologies

158-1872-01 519-Feb-14

3. Configuration

3.1 System Description

This Manual has been written with the objective of giving the reader a sufficient

understanding of the system and its constituent parts in order to be able to install,

commission and operate the system.

3.1.1 General Description

This modular system has been designed specifically to power 24V or 48V

telecommunications equipment requiring accurate temperature compensated Float and

Equalisation voltages, low output noise and EMI levels.

A typical system comprises a number of rectifiers, depending on the power requirement of

the system, and a monitoring and control subsystem comprising a monitoring and control

module (MCSU-4), a User Interface Board (MUIB) and optional modules for monitoring AC

power and battery cell voltages.

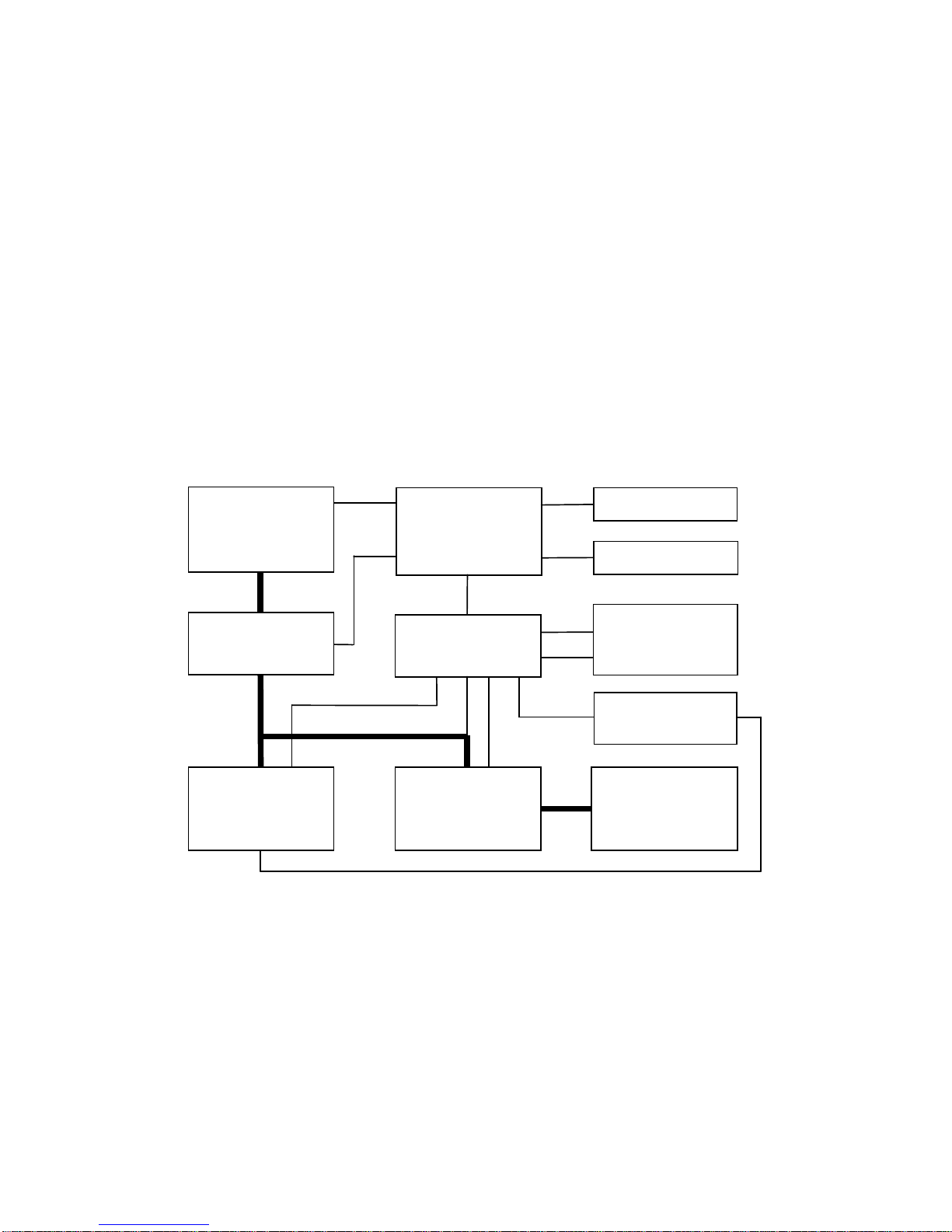

The system can be configured in a number of ways depending on the customer and

application requirements. The simplest option is shown in Figure 3.1.

System Controller

MUIB

(Supplies System

Controller)

AC Distribution

Remote Alarms

and Ambient

Temp. Sensor

DC Bus

DC Distribution

Batteries with

Circuit Breakers

Magazines of

AC-DC Converters

DC Loads

Local Comm. Port

Remote Comm. Port

Figure 3.1 System with basic monitoring and control

The AC Distribution may simply consist of circuit breakers, one for each magazine of

rectifiers in the system, or may also include an isolator, depending on customer

requirements.

The rectifiers housed in one or more magazines are paralleled and the DC output

connected to the load via the DC Distribution module and to the battery bank, which may

be a single battery or two (or more) batteries connected in parallel. A Low Voltage

Disconnect Switch (LVDS) may also be included in series with the batteries in order to

prevent over-discharging the battery bank in the event of an unusually long AC power

outage.

The monitoring and control signals, such as battery currents, temperature, battery switch

status, LVDS control and status, system voltage and ambient temperature are connected

Installation, Operation and Technical Manual Rectifier Technologies

158-1872-01 619-Feb-14

to the monitoring and control module (MCSU-4) via an interface card (MUIB). This module

is in turn connected to the MCSU-4 magazine via a 34 way ribbon cable.

A 10-wire cable, which carries the digital communications signals that allow control and

monitoring of the rectifiers, connects the MCSU-4 to all the rectifiers in a parallel

arrangement so that all the rectifiers receive the same signal.

System status and operating parameters can be accessed from a PC connected to local

communication port on the front panel of the controller.

Remote monitoring of the system can be by means of voltage-free relay contacts.

Standard system uses 3 relays corresponding to SMR shutdown, System Alarm and High

Voltage Shut Down (HVSD).

Alternatively, a remote communication port can be used to display all the system and

rectifier information on a remote PC.

With this facility, it is possible to not only monitor but also control all the rectifier and

system parameters. In addition, the system has the capability to dial up to three telephone

numbers to connect to the remote PC in the event of a system fault having developed, and

will continue dialling until the fault is reported.

Battery Cell Monitor

System Controller

MUIB

(Supplies System

Controller)

AC Distribution

with 1Monitor

Remote Alarms

and Ambient

Temp. Sensor

DC Bus

DC Distribution

Batteries with

Circuit Breakers

Magazines of

AC-DC Converters

DC Loads

Local Comm. Port

Remote Comm. Port

Figure 3.2 System with additional single phase AC Monitor

The second option shown in Figure 3.2 is the basic arrangement described above with the

addition of an auxiliary single phase AC monitoring module and Battery Cell Monitor. This

module, which is mounted in the AC distribution module, connects via a ribbon cable to the

MUIB and is used to monitor the AC voltage, current and frequency .

The third option shown in Figure 3.3 is the basic arrangement with the addition of an

auxiliary three phase AC monitoring module. The latter connects directly to the MCSU-4

via a ribbon cable and provides monitoring of the three AC voltages and currents as well

as the AC frequency. It has multiplexing circuits on board which effectively extends the

analogue monitoring ability of the MCSU-4.

Installation, Operation and Technical Manual Rectifier Technologies

158-1872-01 719-Feb-14

It is possible to have both the single and three phase AC monitoring modules connected at

the same time. This can be useful where the AC output of an inverter running off the 48V

DC bus can be monitored at the same time as the three phase AC supply to the rectifiers.

Battery Cell Monitor

System Controller

MUIB

(Supplies System

Controller)

AC Distribution

with 3Monitor

Remote Alarms

and Ambient

Temp. Sensor

DC Bus

DC Distribution

Batteries with

Circuit Breakers

Magazines of

AC-DC Converters

DC Loads

with 1Inverter

and AC Monitor

Local Comm. Port

Remote Comm. Port

Figure 3.3 System with additional 3 phase AC Monitoring; simultaneous monitoring

of single phase inverter also possible

3.1.2 Rectifier Specific Configurations

A typical mechanical arrangement of a system comprising 4 rectifiers in a mini shelf is

shown in Figure 3.4. It consists of 4 rectifiers (2U total), and a MCSU-4 shelf, for a total of

3U. The arrangement shown is designed to fit into a standard 19” rack. Other

configurations are equally possible.

Figure 3.4 Typical 4 rectifier modular power supply with MCSU-4

Installation, Operation and Technical Manual Rectifier Technologies

158-1872-01 819-Feb-14

4. Installation

4.1 System Installation

The installation of an uninterruptible DC power system incorporating rectifiers, batteries

and control hardware requires compliance to National Wiring Standards, and appropriate

sections of standard IEC60950 to ensure safety of operators and supplementary

equipment. Wiring should always be done by qualified personnel.

4.1.1 Racks

The structure and continuity of the rack provide both system safety compliance and

additional shielding for electromagnetic compatibility (EMC) of the DC power system. The

rack enclosure needs to have the following features to provide safe and efficient system

operation:

The rack must form a basic fire enclosure. To do this, a rack needs a separator or base

plate, which prevents a burning liquid from escaping the enclosure when poured

vertically into the rack. This can be achieved by using either a baffle plate below the

rectifiers with a front finger grill that traps the liquid or a purpose made separation plate

that it mounted below the rectifier magazine to catch burning liquids.

Openings in the top and sides of the enclosure must comply with the following:

not exceed 5mm in any direction, or

not exceed 1mm in width regardless of length, or

for the top of the enclosure, be constructed that direct, vertical entry of falling

objects be prevented from reaching bare parts at HAZARDOUS voltage

(>32VAC or >60VDC), and/or,

for the sides of the enclosure, be provided with louvres that are shaped to deflect

outwards an externally falling object.

Construction of the rack is important in providing exhaust air venting. Cooling louvres,

vent holes or a rack with a ‘top hat’ construction are all good methods of obtaining good

ventilation while maintaining compliance with item ii) above.

The rack needs to be able to mount 19” rack equipment, have a depth not less than

400mm and a minimum height for enclosing the magazine.

4.1.2 Magazines

The magazine configuration metalwork and wiring are usually manufactured as a mini

shelf module with terminal blocks to accept AC wiring and DC output cables. These

magazines should be located in the rack to allow adequate cooling of rectifiers, noting that

the airflow is from the front to the rear of the magazine.

The magazines are held in the rack by M6 screws through the mounting flange and into

the rack mounting rail. All wiring is typically via rear access.

4.1.3 Lightning and Transient Suppression

The rectifiers and magazine contain basic transient suppression in the form of Metal Oxide

Varistors (MOVs) across line-to-neutral, line-to-earth and neutral-to-earth. These MOVs

are sized to provide protection from typical line transients in an industrial environment

according to ANSI C62.41-1991 (6kV/3kA) and IEC 61000-4-5 (Level X). Under these

Installation, Operation and Technical Manual Rectifier Technologies

158-1872-01 919-Feb-14

conditions, the MOVs are expected to provide transient protection for the life of the

rectifiers.

If the transient environment is more severe, with a high incidence of lightning strikes either

indirect or direct, and/or severe switching transients beyond the levels outlined in the

standard, then supplementary transient protection is required. Larger MOVs (40kA rating)

are required at the AC main switchboard where the power to the rack originates.

For wiring systems where the neutral is bonded to the building earth at the main

switchboard (as used for example in Australia, USA, and Canada), one MOV from line-to-

neutral is required for single phase, and three MOVs from each line-to-neutral are required

for three phases.

For wiring systems where the protective earth is bonded to the neutral conductor only at

the distribution transformer, as is common in Europe, three MOVs are required for a single

phase (line-to-neutral, line-to-earth, neutral-to-earth), and seven MOVs are required for

three phase wiring (phase-to-neutral x 3, phase-to-earth x 3 and neutral-to-earth).

4.1.4 Cabling, Auxiliary Equipment and Circuit Breakers

In general, the system needs to have most of the following modules: AC Module, DC

Distribution Module, Battery Circuit Breakers, DC Cabling, Battery Current Transducers,

Temperature Sensors and AC Monitoring Module (optional).

These modules are required inside the rectifier rack for normal system operation. A brief

description of the modules and what they connect to is given below, along with a detailed

rack wiring diagram in Figure 4.1 that shows a system using a MUIB interface.

AC Module: An enclosure containing all the AC circuit breakers (curve C or D) for the

rectifiers, single or three phase active links, neutral links and main protective earth link for

connection to the installation AC system. In any system larger than 3kW, it is advisable to

balance the loads between all three phases. Consultation of local supply authority

requirements is advised.

Note that when using the RT9/10/11 units without a battery, the AC circuit breakers must be a curve-

D type (motor start). This is required to prevent false tripping of the circuit breaker when there are

half-cycle mains interruptions and the subsequent surges. Systems with a battery do not have this

requirement.

DC Distribution: An enclosure containing all the DC load distribution circuit breakers and

usually the Battery string circuit breakers. If the Battery breakers are included in the DC

distribution module, an isolation barrier is usually required along with clear labelling which

battery string the breakers are protecting. The input to the DC distribution module comes

directly from the DC output line of the rectifiers that is NOT connected to the system (DC)

earth.

DC Cabling: The choice of DC cabling and/or busbars is based entirely on the DC current

rating of the system. Consult the local National wiring standard for the selection of

cable/busbar size for the DC connections. One suggested method of DC cabling for

medium systems (~6-8kW) is to provide short 100mm x 6mm busbars at the external DC

interface with a number of holes to attach smaller DC cables. Then connect cables up to

25mm2from the DC terminations to the output terminals of the individual magazines. The

flexibility of the DC cables can be a benefit over fixed busbars when fitting components

into a rack with limited space.

Installation, Operation and Technical Manual Rectifier Technologies

158-1872-01 10 19-Feb-14

Figure 4.1 Typical System Wiring

Battery Current Transducers: A Hall effect current measuring unit that is installed over the

cable connecting the battery string to its circuit breaker. The signal lines are connected to

terminal on the MUIB.

Temperature Sensors: Modules typically assembled in a copper lug with a mounting hole

at one end and sensor cabling running from the other sealed end to terminals in the MUIB.

The sensors are normally placed in the battery compartment to measure battery

temperatures.

AC Monitoring Module: Optional modules are available in either single phase or three

phase models. The module connects in series with the incoming mains supply by having

the phase wires inserted through the current sensors on the module before having the

terminating at the active link. The phase-neutral (or phase-phase) voltages are separately

sensed by reference transformers. Inputs for voltage measurement are protected against

high voltage transients. The modules are connected to the MCSU-4 magazine via a 16-

way ribbon. If both types of modules are installed use the second 16-way connector on

single phase module for connection to the three phase module.

DC voltage regulation and power for the MCSU-4 is derived from the output DC bus via

the connections on the MUIB. The connection point is made where a constant voltage is

most useful. This is typically at the point where the cables run to the batteries. External

voltage sensing for voltage regulation at a load can also be done, but in most systems, the

system voltage is sensed on the internal output bus. For more information, see the

detailed section on the MUIB.

Installation, Operation and Technical Manual Rectifier Technologies

158-1872-01 11 19-Feb-14

4.2 Rectifier Installation and Removal

In the system, the rectifiers are designed to operate in parallel in a N+1 redundant mode.

Therefore, there is never a situation in which it is necessary to set individual rectifier

parameters.

The rectifiers are designed to be “hot pluggable” in that they can be plugged into and out

of a “live” magazine. Due to the small size of energy storage elements in the rectifier

output, there is no significant disturbance to the DC bus when a rectifier is plugged into the

magazine.

An inrush limiting circuit in the AC input circuit that utilises a relay and an inrush current

limiting resistor limits the disturbance to the AC source to an acceptable level when a unit

is plugged in with AC voltage present on the AC bus.

4.2.1 To Remove a Rectifier from the Magazine

Although the connectors are designed to be “hot pluggable” it is advisable to first switch off

power to the unit by means of the circuit breaker in the AC distribution module before

unplugging the unit. This is done to prolong the life of the rear “hot pluggable” connector.

Each rectifier 1U shelf has a spring clip that secures the rectifiers in place once it is

plugged into its magazine. First lift the clip, then, using the finger recess in the front, pull

the rectifier from the magazine.

WARNING !!

Take care when removing the rectifier as it may be uncomfortably hot to hold especially if

the ambient temperature is high and the unit has been operating at maximum load.

4.2.2 Inserting a Rectifier into the Magazine

Although the connectors in the unit are designed for “hot pluggability” it is advisable to turn

off the AC power to the input connector by means of the related circuit breaker in the AC

distribution module before plugging in the unit.

Carefully slide the rectifier into the magazine. Press the unit into the magazine until it is

flush and the spring retaining clip clicks down. This ensures that it will not fall out in the

event of severe shaking as might occur in the event of an earthquake.

Switch on the relevant AC circuit breaker in the AC distribution module. The rectifier will

start automatically and connect itself to the DC bus at the appropriate time.

Installation, Operation and Technical Manual Rectifier Technologies

158-1872-01 12 19-Feb-14

4.3 MUIB - Mini User Interface Board

Connections between the MCSU-4, the external transducers and other inputs are made

using the connectors provided on the MUIB. Terminals are provided for alarm relay

contacts, battery and ambient temperature sensors, two battery current transducers, LVDS

control and circuit breaker operation detection using the breaker auxiliary contacts for both

the battery and load circuit breakers.

4.3.1 MUIB Connections

4.3.1.1 Relay Contact Outputs

There are 5 relays with normally open (N/O) and normally closed (N/C) contacts available

on the MUIB, connector X2 (see Figure 4.3). In standard RTP system three of the relays

are for remote annunciation of alarms: Relay 3 - HVSD, Relay 4 – any system alarm,

Relay 5 - SMR shut down.

Other two relays are used for control of optional external equipment.

Relay 2 is programmed for FAN CONTROL. If any one of the SMR heat-sink temperatures

exceeds a pre-set (non-programmable) value, the relay closes. The relay closure can then

be used to either speed up fans, which may normally be idling at low speed, or it can turn

on fans, which may normally be off.

In 110V systems Relay 1 closes during battery discharge test, allowing control of dummy

load on standby systems. In 24V and 48V systems it has no assigned function.

If MCSU-4 supports User Programmable Relays, the functions described above can be

changed on site according to specification of the installation (for details see paragraph

“User programmable relay functions” in chapter “Operation”). It is also possible to

permanently assign different functions to the relays on end user request by modifying

controller software.

4.3.1.2 Spare Digital and Analog Inputs

There are 4 spare digital inputs (USER 1, 2, 3, 4) available on the MUIB for the monitoring

of external plant associated with the power supply. The inputs must be isolated relay

contacts or auxiliary contacts, which are either normally open or normally closed.

There is also provision for monitoring two external analog levels via connectors X28 (AN1)

and X31 (AN2) on the MUIB. The analog signals must be in the range 0 to +5VDC.

To use the spare analog or digital inputs the software for the MCSU-4 must be individually

programmed by the manufacturer according to the requirements of the application.

4.3.1.3 Battery Current Transducer Input

Battery current transducers are connected to X39 and X40 of the MUIB. Figure 4.2 shows

the pin connections for the battery transducer connector going onto the MUIB.

Installation, Operation and Technical Manual Rectifier Technologies

158-1872-01 13 19-Feb-14

Figure 4.2 Battery transducers connection to MUIB

Figure 4.3 MUIB Connection Diagram

X1

X2

X18

X17

X28

X31

X32

X22

X23

X33

X34

X44

X45

X39

X40

34-way ribbon

cable to MiniCSU

X50

X64

X65

Conn #

Conn Label

Class

Used for:

X1

MiniCSU

Anal/Dig

34-way ribbon cable to MiniCSU

X2

RELAY 1

Digital

Dummy load on 110V systems, not used on other systems

RELAY 2

“

Cabinet Fan control for RT4 or RT5 systems

RELAY 3

“

SMR HVSD Alarm

RELAY 4

“

Activated by any alarm condition

RELAY 5

“

SMR switched off (for any reason)

X17

BAT. TEMP.

Analog

Temperature Transducer

X18

AMB. TEMP.

Analog

Temperature Transducer

X22

C.B. TRIP

Digital

Aux contact from load CBs

X32

1 PHASE AC

Anal/Dig

Not used with MCSU-4

X23

BAT. SW.

Digital

Aux contact from Batt. CBs

X33

USER 1

Digital

User defined i/p; isolated aux. Contact or similar

X34

USER 2

Digital

Requires special software to define function

X44

USER 3

Digital

“ “

X45

USER 4

Digital

“ “

X28

AN 1

Analog

Spare analog I/P - 0 to 5VDC (Requires special software)

X31

AN 2

Analog

Spare analog I/P - 0 to 5VDC (Requires special software)

X39

BATTERY 1

Analog

Battery current transducer

X40

BATTERY 2

Analog

Battery current transducer

X50

POWER I/P

Analog

System voltage sensing and DC power input for MiniCSU

X64

LVDS Aux

Digital

Aux contact from LVDS contactor

X65

LVDS Coil

Digital

Drive for contactor or similar

Installation, Operation and Technical Manual Rectifier Technologies

158-1872-01 14 19-Feb-14

Figure 4.4. MUIB Connectors wiring information

Connector

Pin

Signal Name

Connector

Pin

Signal Name

X1 MCSU-4

1-34

34 way ribbon

X32 1 PHASE AC

1-10

Not used with MCSU-4

X2 RELAY 1

(USER)

15

N/O relay contact

X39 BATTERY 1

1

-15V

14

N/C relay contact

2

+15V

13

Common

3

No connection

X2 RELAY 2

(FAN SPEED)

12

N/O relay contact

4

Input

11

N/C relay contact

5

GND

10

Common

X40 BATTERY 2

1

-15V

X2 RELAY 3

(HVSD)

9

N/O relay contact

2

+15V

8

N/C relay contact

3

No connection

7

Common

4

Input

X2 RELAY 4

(ALARM)

6

N/O relay contact

5

GND

5

N/C relay contact

X22 C.B. TRIP

1-2

Contact closure required

between pins 1 and 2

4

Common

X23 BAT SW.

1-2

“ “

X2 RELAY 5

(SMR S/D)

3

N/O relay contact

X33 USER1

1-2

“ “

2

N/C relay contact

X34 USER2

1-2

“ “

1

Common

X44 USER3

1-2

“ “

X17 BAT TEMP.

1

No connection

X45 USER4

1-2

“ “

2

Sensor -ve

X50 POWER I/P

1

Bat +ve terminal

3

Sensor +ve

2

Bus +ve terminal

X18 AMB. TEMP

1

No connection

3

No connection

2

Sensor -ve

4

Battery -ve terminal

3

Sensor +ve

5

Bus -ve terminal

X28 AN1

1

0V to +5Vdc.

X64 LVDS Aux.

1-2

LVDS auxiliary contact

2

Common

X65 LVDS Coil

1-3

Coil driving voltage

X31 AN2

1

0V to +5Vd

2

No connection

2

Common

Installation, Operation and Technical Manual Rectifier Technologies

158-1872-01 15 19-Feb-14

Figure 4.5. MUIB Fuse Function and Specification

Fuse

Function

Specification

F4

+15VDC

F500mA, Glass, M20x5

F5

-15VDC

F500mA, Glass, M20x5

F8

Ground

T2A, HRC, M20x5

F46

-V System

T2A, HRC, M20x5

F49

-V Battery

T2A, HRC, M20x5

F53

+V System

T2A, HRC, M20x5

F63

+V Battery

T2A, HRC, M20x5

F68

+V LVDS

T2A, HRC, M20x5

F69

-V LVDS

T2A, HRC, M20x5

Installation, Operation and Technical Manual Rectifier Technologies

158-1872-01 16 19-Feb-14

4.4 MUIB2 - MCSU-4 User Interface Board (type2)

The MUIB2 is an optional module that may be used in place of the MUIB to allow

monitoring of a total of four battery currents and to directly measure one load current. The

MUIB2, like MUIB provides basic interfacing between the MCSU-4 and the system

environment. Use of this board also requires a specific MCSU-4 software version.

The addition of the load current transducer input allows the MCSU-4 to sense the load

current directly. This provides better resolution of the load current than the calculated

current determined from the reported individual rectifier output currents. This is because

there is an inherent resolution limit for each rectifier current measurement that can

significantly degrade the load current resolution when a system contains a large number of

rectifiers. Another use of the load current transducers is when non-RTP rectifiers are used

with a MCSU-4, and these rectifiers do not signal their current to the MCSU-4.

The current transducers are standard 4V full scale. Accuracy of signal conditioning for the

current signals is typically 1%.

4.4.1 System setup requirement

The MCSU-4 software needs to be a version with an MUIB2 option. This board needs to

be enabled from the front panel of the MCSU-4 or PC running WinCSU-2 program. The

load transducer also needs to be enabled or disabled as necessary. The full scale value

of battery and load transducers then needs to be entered.

4.4.2 Main features of MUIB2

The principal features of the MUIB2 are as follows:

Each battery current input accepts input range of -4V to +4V full scale. The maximum allowed input is

5V

The load current input range is from 0V to +4V. The maximum allowed input is 0 to +5V.

The battery and load full scale currents are separated so different transducers for battery and load

currents can be used.

Signal conditioning accuracy for the battery and load currents is typically 1%.

Actual number of batteries used can be programmed via MCSU-4 front panel or WinCSU-2 remotely.

Load transducer can be switched on or off via MCSU-4 front panel or WinCSU-2 remotely.

When the load transducer is switched off, MCSU-4 automatically reverts back to calculating load current

using SMR and battery currents.

There are 5 relay outputs, 4 digital inputs, LVDS interface, CB trip input and Battery switch input.

Ambient and battery temperature sensors can be connected to this board.

The MUIB2 also provides power to the MCSU-4, this board can be connected to the bus and battery at

the same time.

Two spare analog inputs are available (input range: 0 to +5V).

4.4.3 MUIB2 Connections

The MUIB2 connector wiring diagram is shown in the table of Figure 4.9, followed by the

connection diagram and connector legend in Figure 4.12.

4.4.3.1 Relay Contact Outputs

There are 5 relays with normally open (N/O) and normally closed (N/C) contacts available

on the MUIB2, connector X2. In standard RTP system three of the relays are for remote

This manual suits for next models

1

Table of contents