10

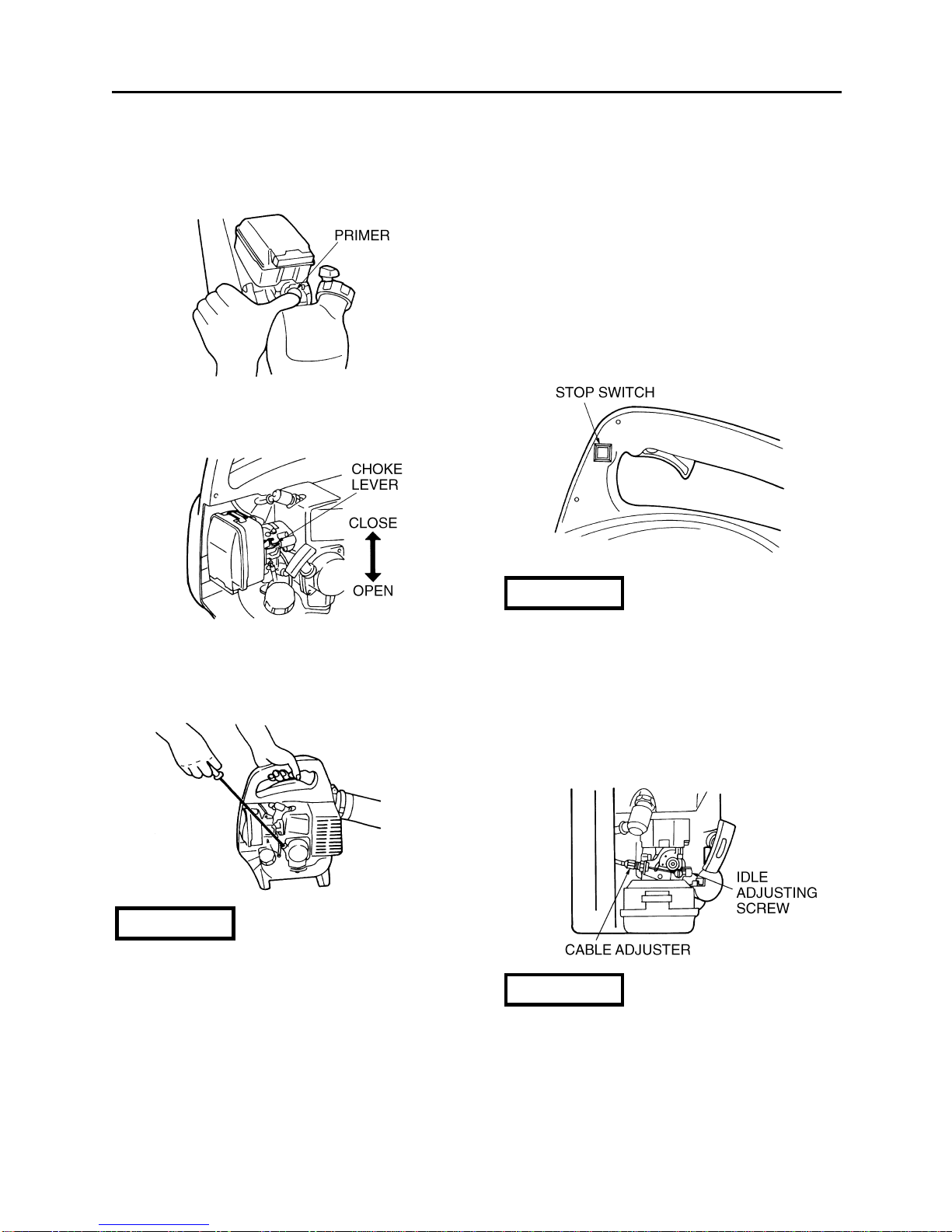

■FUEL FILTER

•A clogged fuel filter may cause poor

acceleration of the engine. Check

periodically to see if the filter is clogged

with dirt. The filter can be taken out of the

fueling port using a small wire hook.

Disconnect the filter assembly from the fuel

pipe and unhook the retainer to

disassemble it. Clean the components with

gasoline.

■SPARK PLUG

•The spark plug may gather carbon deposits

on its firing end with reasonable use.

Remove and inspect the spark plug every

25 hours and clean the electrodes as

necessary with a wire brush. The spark gap

should be adjusted to .025 in.

•Plug manufacturers recommend replacing

the plug twice a year to avoid unexpected

plug failure in a job.

REPLACEMENT PLUG IS A CHAMPION

RCJ6Y.

•Note that using any spark plugs other than

those designated may result in the engine

failing to operate properly or in the engine

becoming overheated and damaged.

•To install the spark plug, first turn the plug

until it is finger tight, then tighten it a

quarter turn more with a socket wrench.

IMPORTANT

•Make sure that the engine has stopped

and is cool before performing any

service to the blower. Contact with

rotating blower fan or hot muffler may

result in a personal injury.

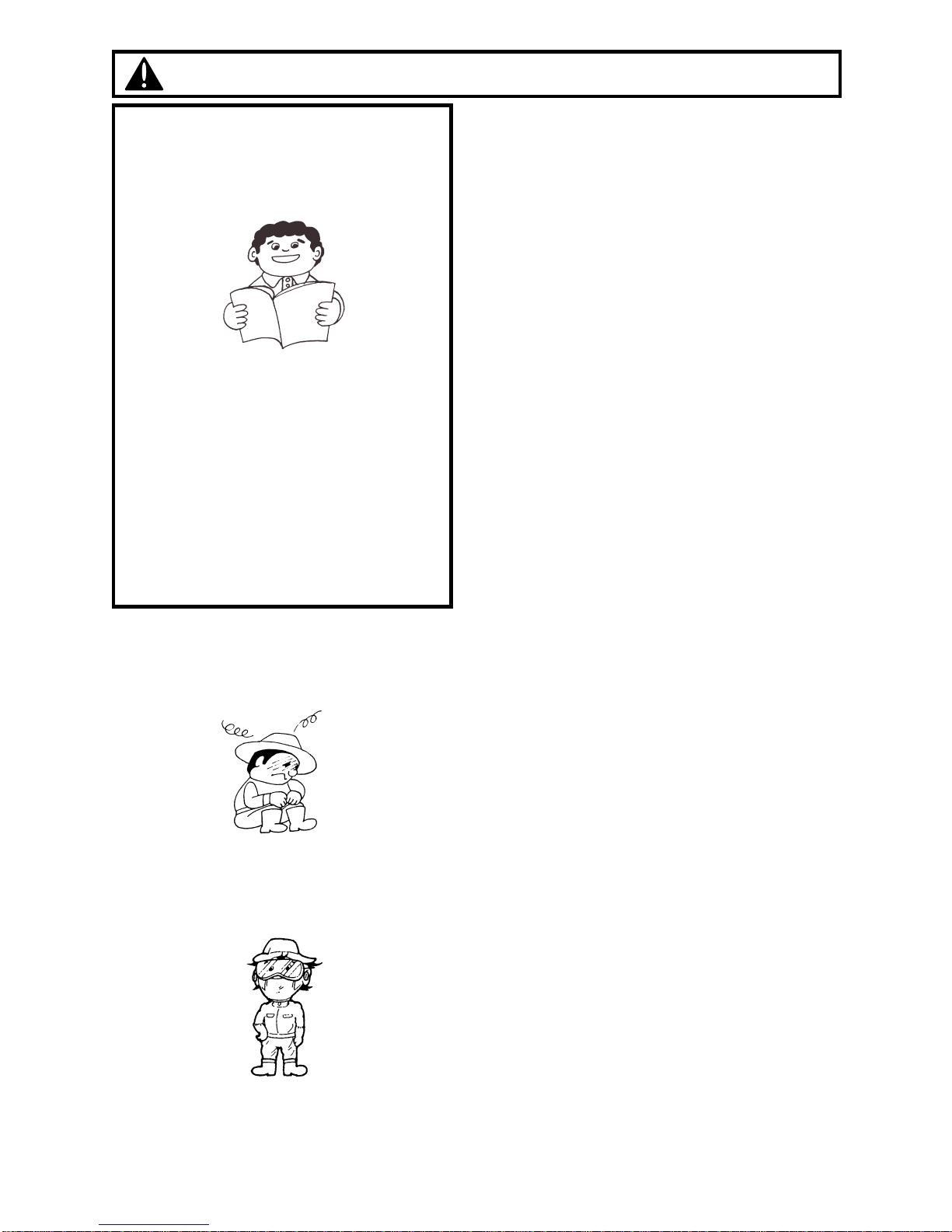

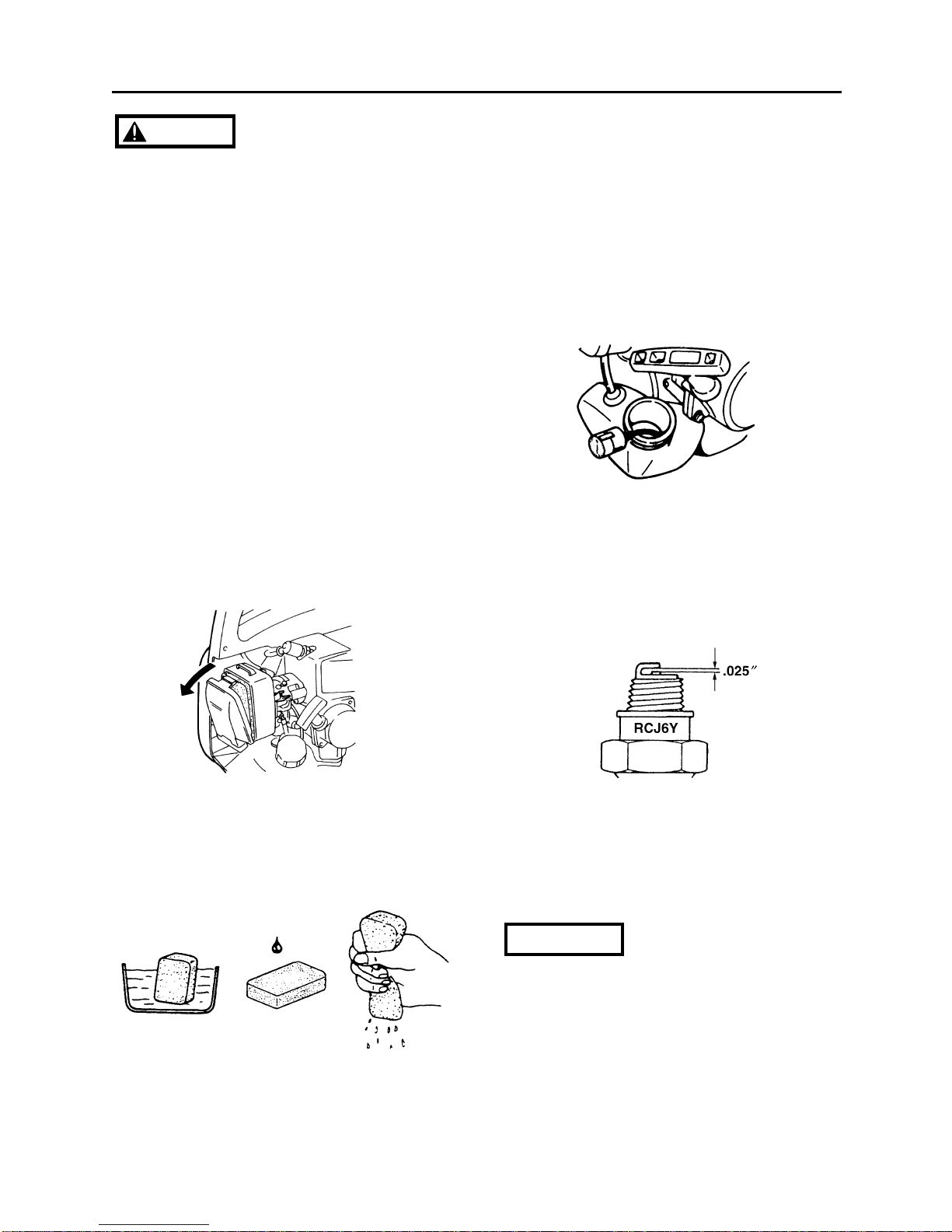

■AIR CLEANER

•Check the air cleaner every 25 hours of

use or more frequently if used under dusty

conditions. A clogged air filter may increase

fuel consumption while cutting down the

engine power. Never operate the blower

without the air filter or with a deformed filter

element because unfiltered dusty air will

quickly ruin the engine.

CLEANING AIR FILTER:

1.Remove the air cleaner cover by pulling

the tab on bottom and take out the filter

element.

2.Use neutral detergent and warm water to

clean the filter element. After cleaning, air

dry the element completely and moisten

with a small amount of motor oil.

3.Place the filter element into the air cleaner

housing and press the cover against the

housing until it clicks.