Fillcontrol Auto Make-up and degassing — 06.07.2016 - Rev. B English —

English

FillcontrolAutoM ake-up and degassi ng

06.07.2016-Rev. B

Contents

1Notes on the operating manual.....................................................................................................................................................5

2Liability and guarantee...................................................................................................................................................................5

3Safety................................................................................................................................................................................................6

3.1 Explanation of symbols........................................................................................................................................................................6

3.1.1 Symbols and notes used...................................................................................................................................................6

3.2 Personnel requirements ......................................................................................................................................................................7

3.3 Personal protective equipment ..........................................................................................................................................................7

3.4 Intended use..........................................................................................................................................................................................7

3.4.1 Fillcontrol Auto 2P.............................................................................................................................................................7

3.4.2 Fillcontrol Auto 2PS...........................................................................................................................................................7

3.5 Inadmissible operating conditions.....................................................................................................................................................8

3.6 Residual risks .........................................................................................................................................................................................8

4Description of the device................................................................................................................................................................9

4.1 Description.............................................................................................................................................................................................9

4.2 Overview ..............................................................................................................................................................................................10

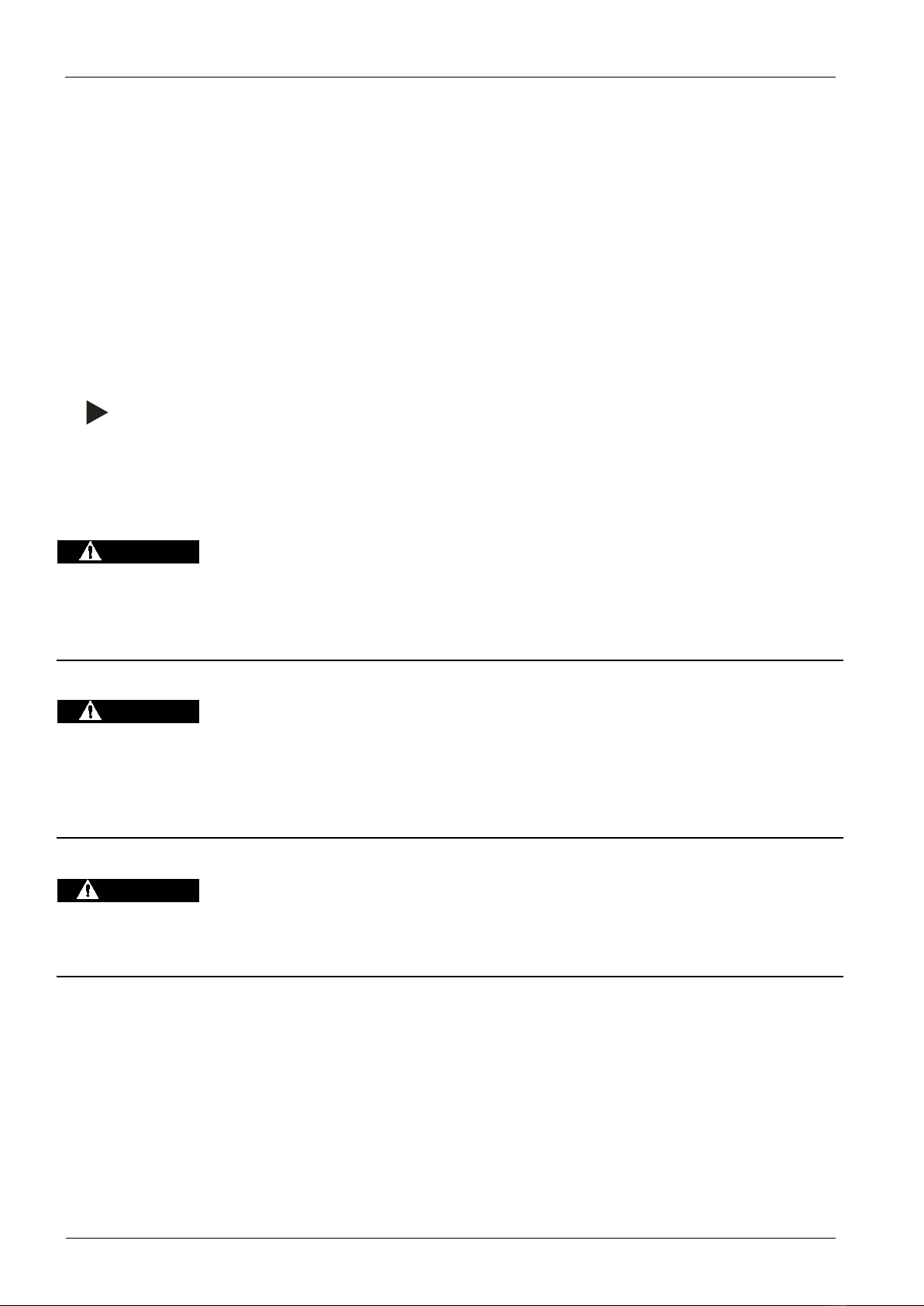

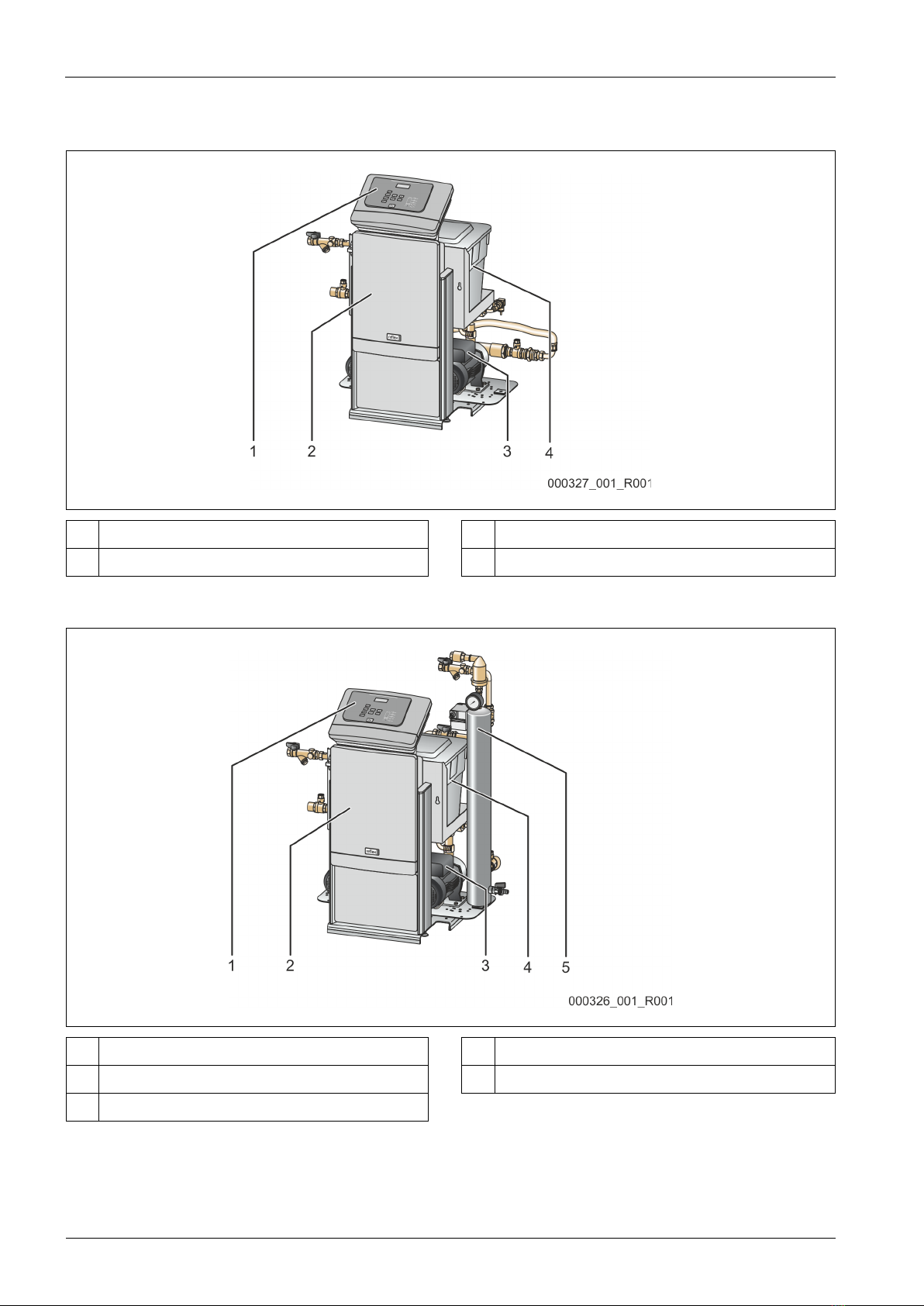

4.2.1 Fillcontrol Auto 2P...........................................................................................................................................................10

4.2.2 Fillcontrol Auto 2PS.........................................................................................................................................................10

4.3 Identification .......................................................................................................................................................................................11

4.3.1 Nameplate ........................................................................................................................................................................11

4.3.2 Type code..........................................................................................................................................................................11

4.4 Function ...............................................................................................................................................................................................12

4.4.1 Fillcontrol Auto 2P...........................................................................................................................................................12

4.4.2 Fillcontrol Auto 2PS.........................................................................................................................................................13

4.5 Scope of delivery.................................................................................................................................................................................15

4.6 Optional equipment and accessories ..............................................................................................................................................15

5Technical data ...............................................................................................................................................................................16

5.1 Electrical system..................................................................................................................................................................................16

5.2 Dimensions and connections............................................................................................................................................................16

5.3 Operation .............................................................................................................................................................................................16

6Installation.....................................................................................................................................................................................17

6.1 Installation conditions .......................................................................................................................................................................18

6.1.1 Incoming inspection .......................................................................................................................................................18

6.2 Preparatory work ................................................................................................................................................................................18

6.3 Execution..............................................................................................................................................................................................19

6.3.1 Fitting the add-on components....................................................................................................................................19

6.3.2 Floor mounting................................................................................................................................................................20

6.3.3 Hydraulic connection......................................................................................................................................................21

6.3.4 Fillcontrol Auto 2P...........................................................................................................................................................21

6.3.5 Fillcontrol Auto 2PS.........................................................................................................................................................22

6.4Electrical connection ..........................................................................................................................................................................24

6.4.1 Control cabinet terminal plan........................................................................................................................................25

6.4.2 Terminal plan, operating unit........................................................................................................................................27

6.5 Installation and commissioning certificate.....................................................................................................................................28

7Commissioning..............................................................................................................................................................................29

7.1 Requirements for initial commissioning .........................................................................................................................................29

7.2 Determining the P0minimum operating pressure for the controller.........................................................................................29

7.3 Filling the device with water.............................................................................................................................................................30