5

DESCRIPTION AND OPERATION

Description and Operation

Device Function

Regula 7505M is designed for non-destructive investigation of metal surface and for

document examination to control their authenticity and detect falsication of VINs and vehicle

documents

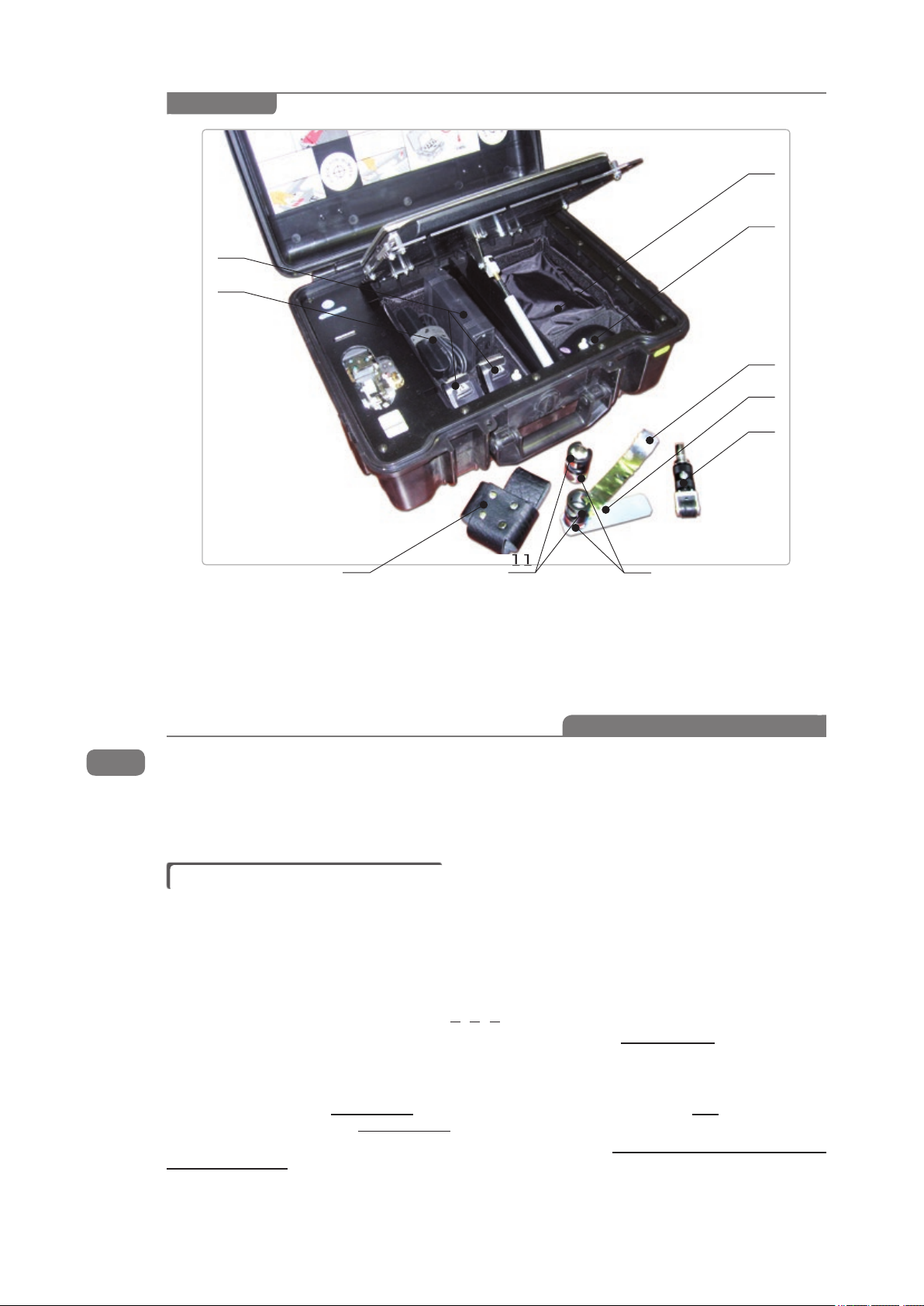

The device is a set of hardware and software products enabling visualization (video imaging)

of the relief and structural inhomogeneity of the metal surface with magnetic properties

(traces of mechanical processing, inclusion of non-ferromagnetic materials, surface aws of

welding seams), without removing the lacquer-and-paint coating (if applicable) by methods of

magneto-optical visualization A PC is used for capturing, collecting, processing, transferring

and displaying information

The device is intended for use by forensic laboratories, law enforcement agencies, judicial

authorities, customs and insurance companies As Regula 7505M provides high-quality

results, uses non-destructive methods, operative and obvious character of magneto-optical

investigations, it can be used for express inspection (eg at customs or by highway patrol),

as well as for advanced forensic examination of vehicle VINs in laboratory conditions In case

any VIN changes are detected, further investigations can be carried out using a special set of

peripheral hardware tools (supplied optionally) suitable for a case

Application

Objects of control are divided into two categories:

Category “A” —

vehicle unit surface (data carrier –

body, engine and chassis) with relief

identication number applied by

mechanical processing, electro sparking

or laser mode

Data carriers of integral body frame

in mass production passenger cars are

normally made of sheet steel: RRST 1405

(DIN 1623 quality standard) cold rolled

sheet steel; UST 1203, UST 1303 unkilled

sheet steel Exceptions are made for

Audi A8/S8 series bodies, produced

since February 1994, because their body

panels are made of aluminum alloys

Engine cylinder blocks are mostly made

of special cast iron and aluminum alloys

Thickness of non-magnetic coating

(galvanic and lacquer-and-paint coating)

of manufactured vehicle body parts

is 185 μm (with 6 layer coating); but

typically it is 40-80 μm

Category “B” —

materials and printing methods of vehicle

related documents

Device components enable to examine vehicle

related documents security features activated in

different spectral ranges (absorption, reection,

luminescence) when they are viewed under lights

with different wavelengths (for more information

see Spectral Luminescent Magnier Regula 4177

Operational Manual)

1

1.1

1.1.1