MAN-099-EN - rev.02 EN 2

CONTENTS

1. GENERAL.................................................................................................................3

1.1 Safety instructions ...........................................................................................3

1.2 Safety notes on the equipment operation..........................................................3

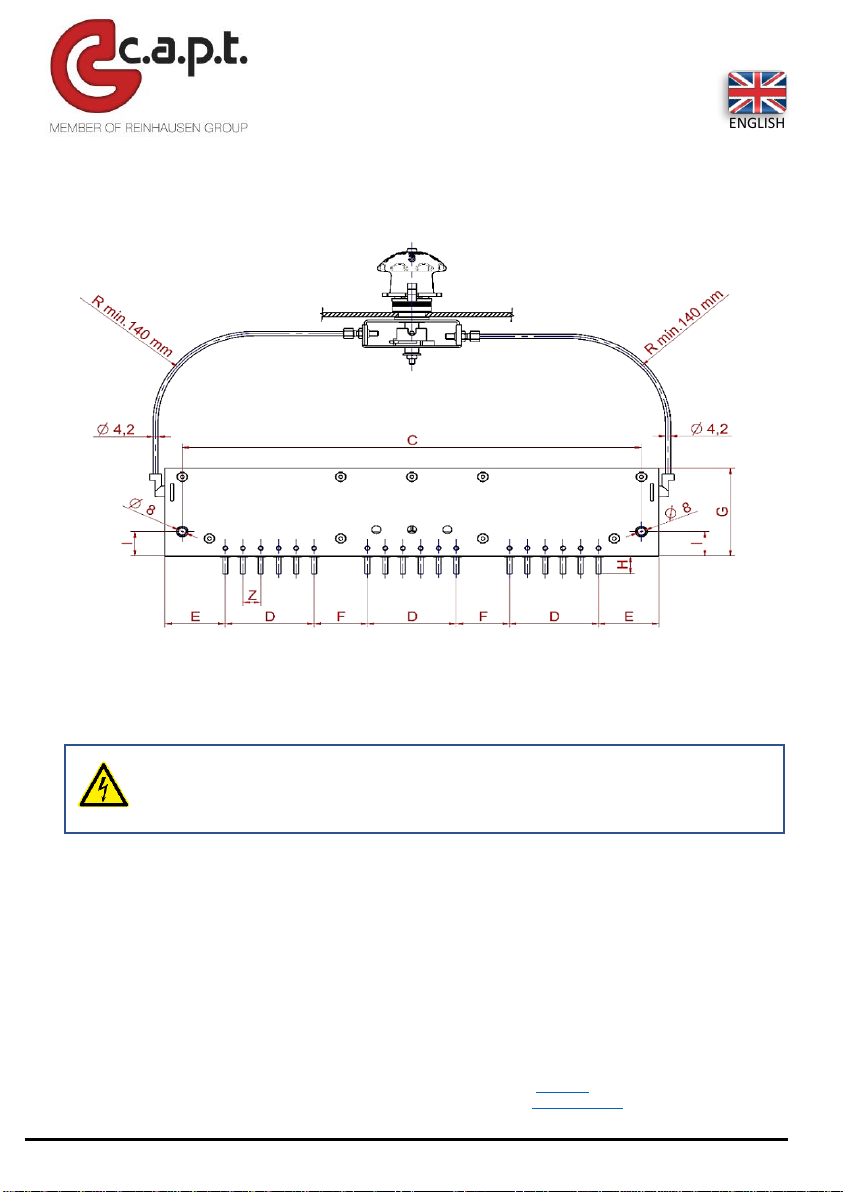

2. DESIGN ...................................................................................................................4

2.1 Drawing ..........................................................................................................4

2.2 Generality .......................................................................................................4

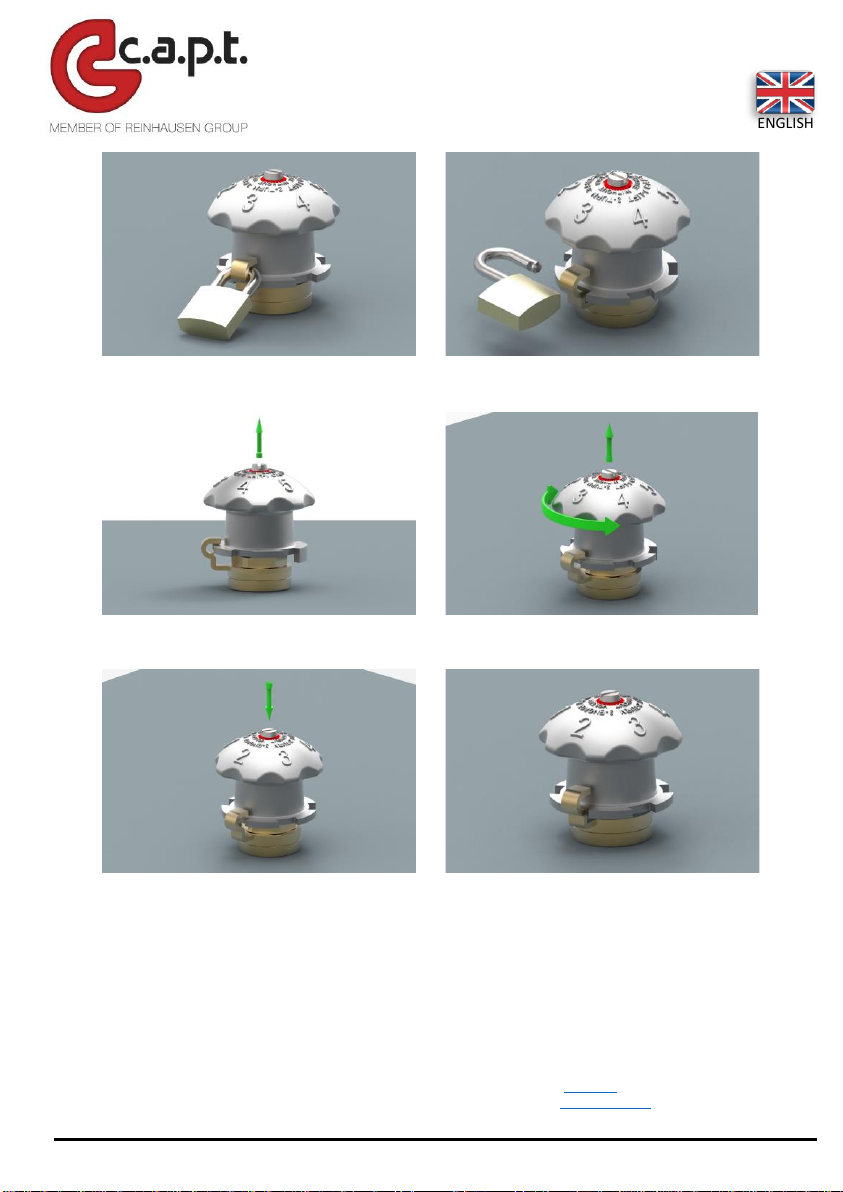

2.3 Drive handle....................................................................................................5

2.4 Technical features............................................................................................5

3. SHIPMENT...............................................................................................................5

3.1 Shipment ........................................................................................................5

3.2 Storage ...........................................................................................................6

4. USE AND MAINTENANCE ..........................................................................................6

4.1 Use.................................................................................................................6

4.2 Maintenance...................................................................................................8

5. INSTALLATION .........................................................................................................8

5.1 Tap-changer ....................................................................................................8

5.2 Preparation of cover or tank wall ......................................................................9

5.3 Mounting of the drive handle ...........................................................................9

5.4 Cable mounting and setting............................................................................12

5.5 Connection of tap winding and tap changer take-off leads................................15

6. DRYING PROCEDURE..............................................................................................16

6.1 Drying procedure...........................................................................................16

7. WHEN CONTACTING C.A.P.T. ..................................................................................17