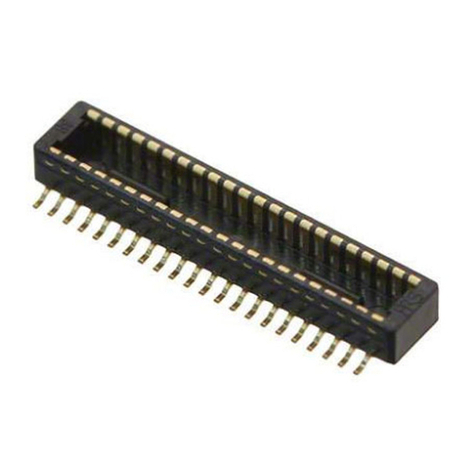

HRS FH12 Series User manual

Other HRS Cables And Connectors manuals

HRS

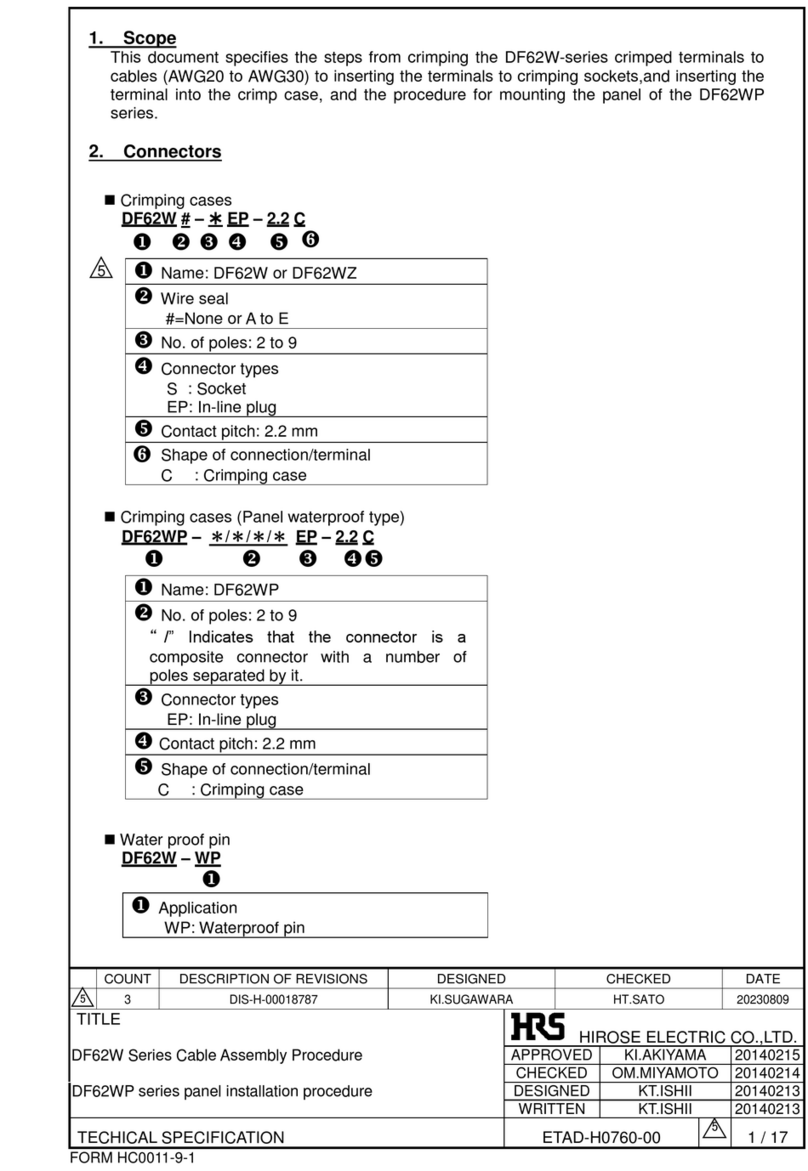

HRS DF62W Series User manual

HRS

HRS BM25 Series User manual

HRS

HRS FH67 Series User manual

HRS

HRS GT50 Series Instruction Manual

HRS

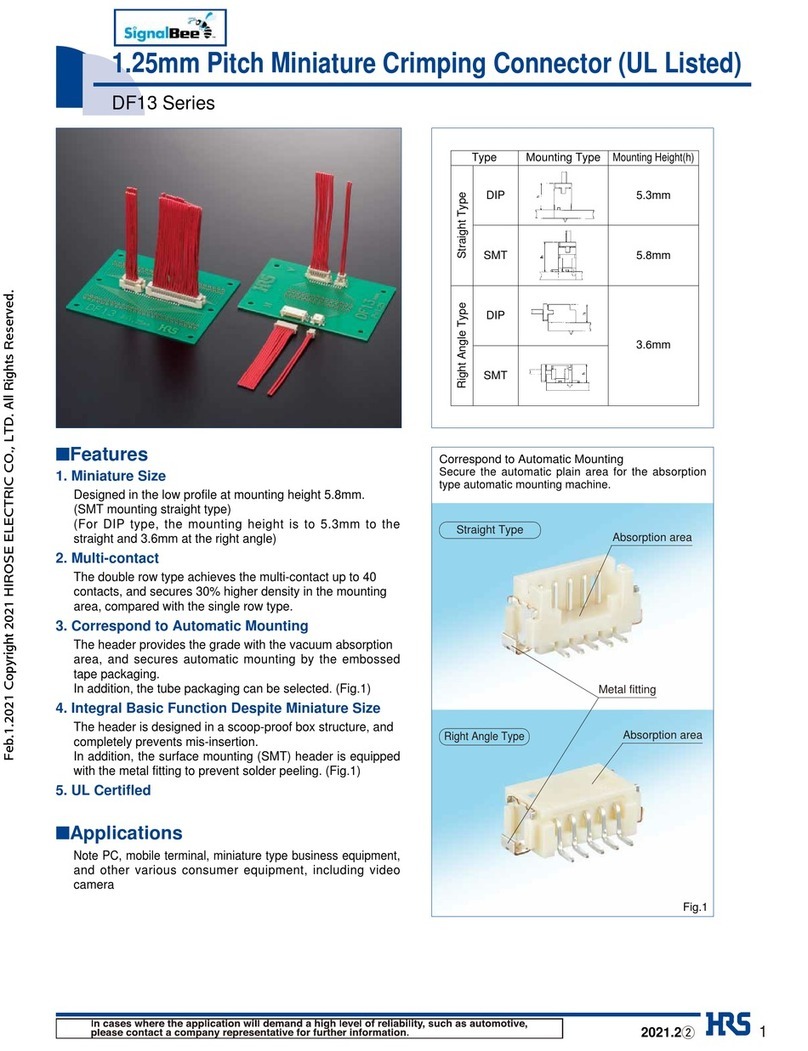

HRS SignalBee DF13 Series User manual

HRS

HRS EM30MSD Series User manual

HRS

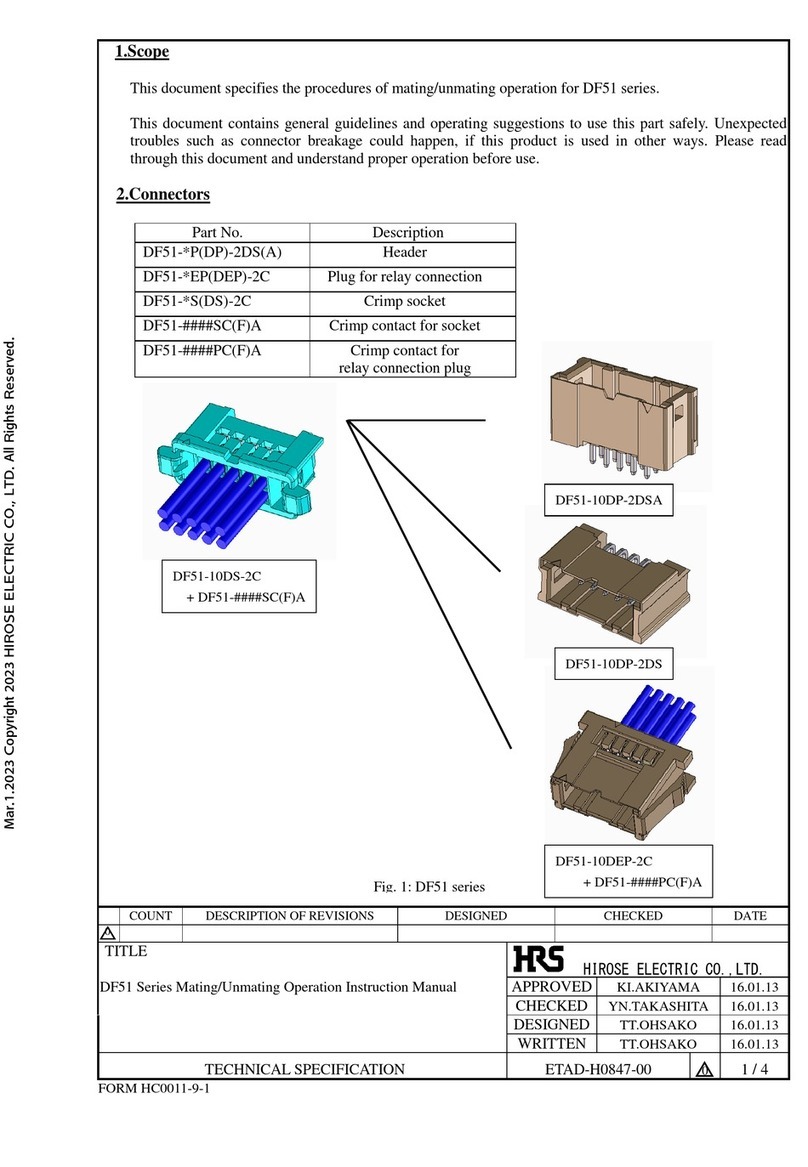

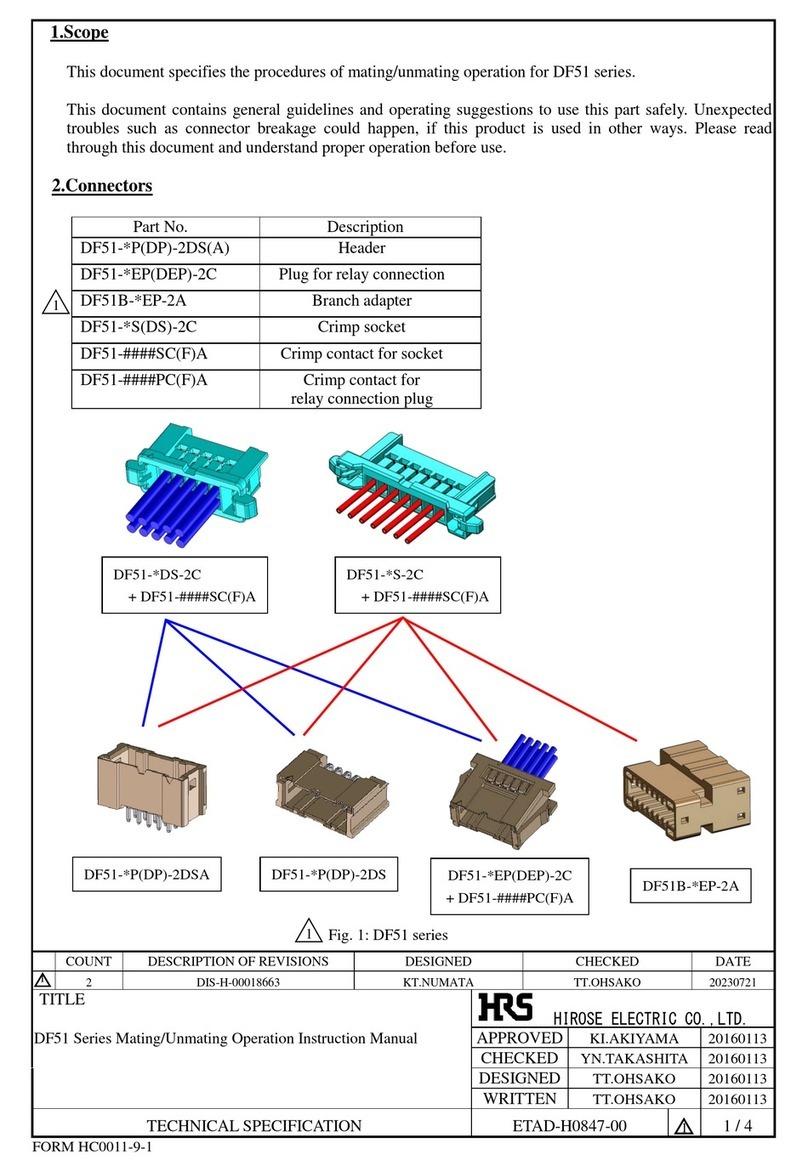

HRS DF51 Series User manual

HRS

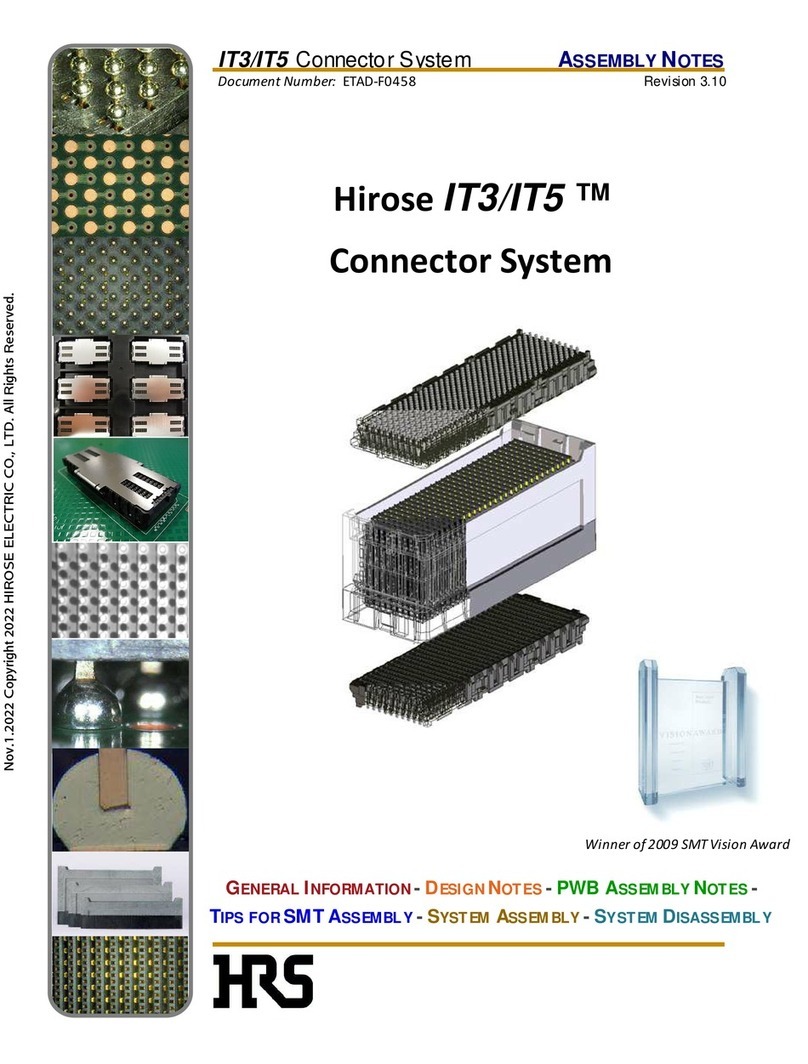

HRS Hirose IT3 Quick start guide

HRS

HRS GT36 User manual

HRS

HRS DF63 Series User manual

HRS

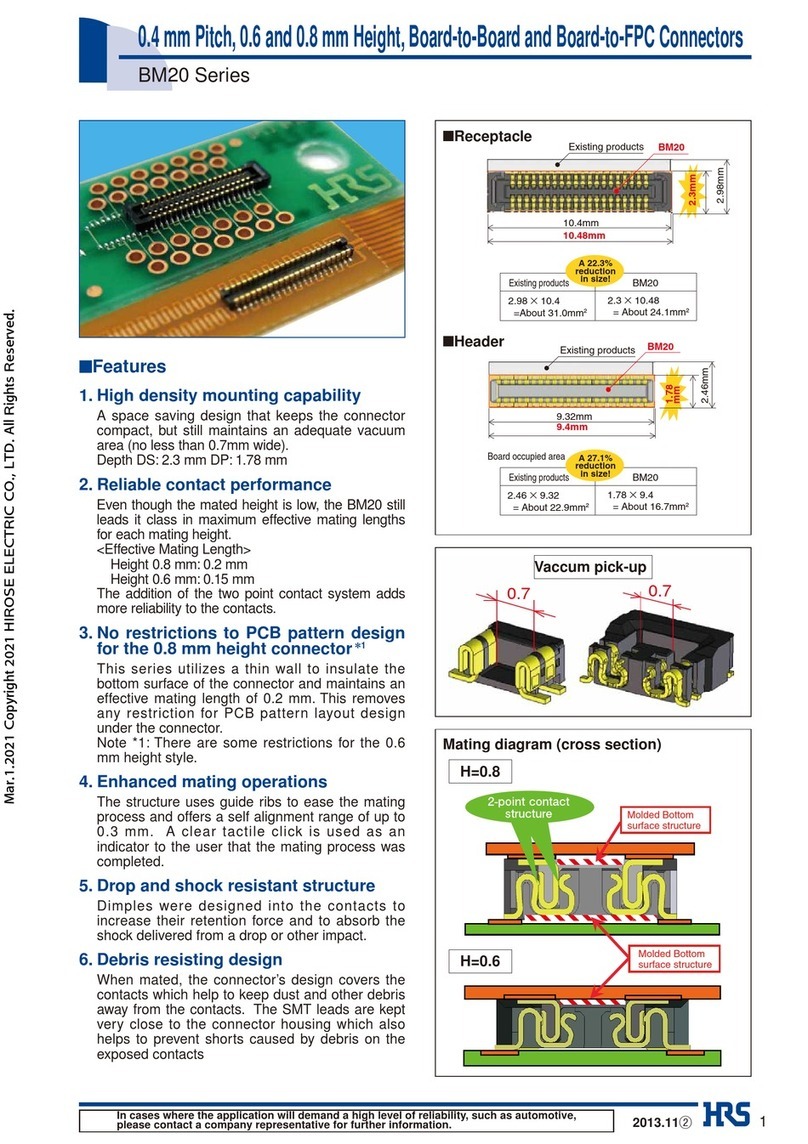

HRS BM20 Series User manual

HRS

HRS DF62W EP 2.2C Series User manual

HRS

HRS GT50 Series User manual

HRS

HRS DF51-6EP-2C User manual

HRS

HRS HIF Series User manual

HRS

HRS ZE05 Series User manual

HRS

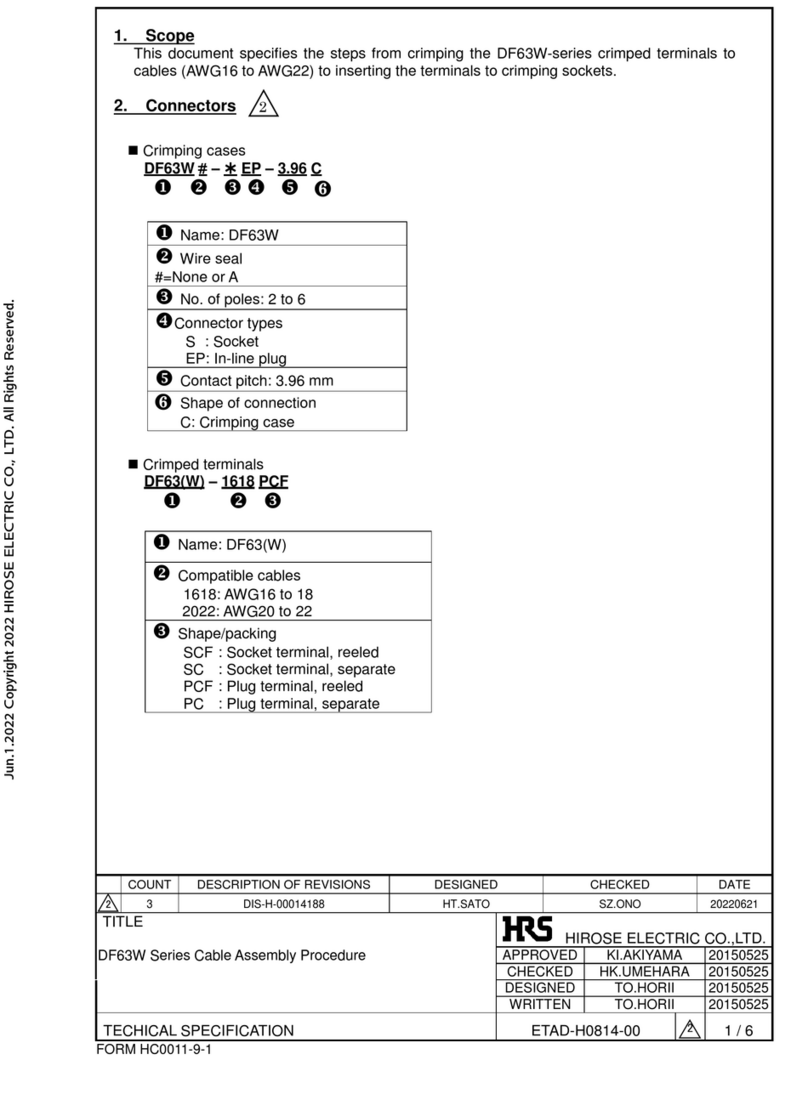

HRS DF63W Series Manual

HRS

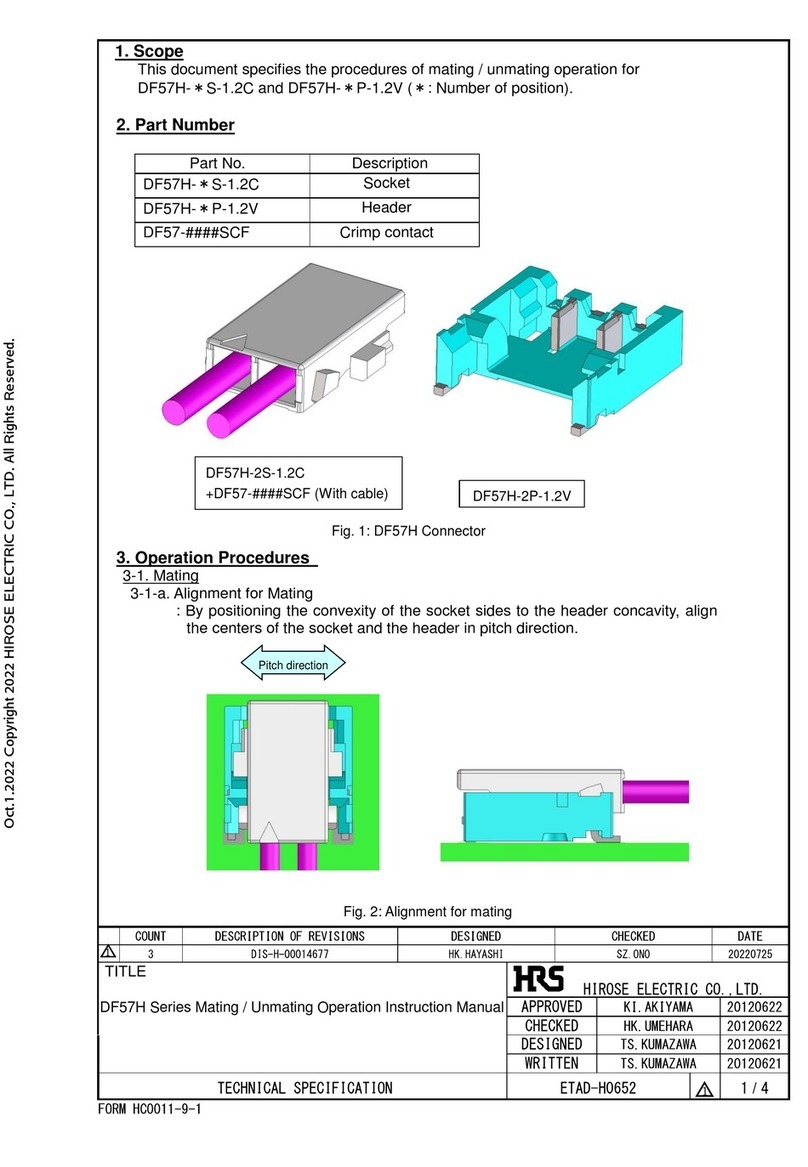

HRS DF57H S-1.2C Series User manual

HRS

HRS BM25 Series Instruction Manual

HRS

HRS DF40 Series User manual