1Safety.........................................................................................................................................4

1.1 Residual risks....................................................................................................................................4

1.2 Information and obligations for the operator .....................................................................................4

1.3 Intended use .....................................................................................................................................4

1.4 Impermissible operating conditions...................................................................................................5

2System description...................................................................................................................6

2.1 Function ............................................................................................................................................6

2.2 System overview ...............................................................................................................................6

2.2.1 Description of the components ...........................................................................................6

2.2.2 Scope of delivery ................................................................................................................7

3Transport / storage ...................................................................................................................7

4Unpacking and installation ......................................................................................................7

4.1 Unpacking .........................................................................................................................................7

4.2 Installation requirements ...................................................................................................................7

4.3 System component installation .........................................................................................................8

4.4 "Plasma control" installation software ...............................................................................................8

5Operation...................................................................................................................................9

5.1 Start-up..............................................................................................................................................9

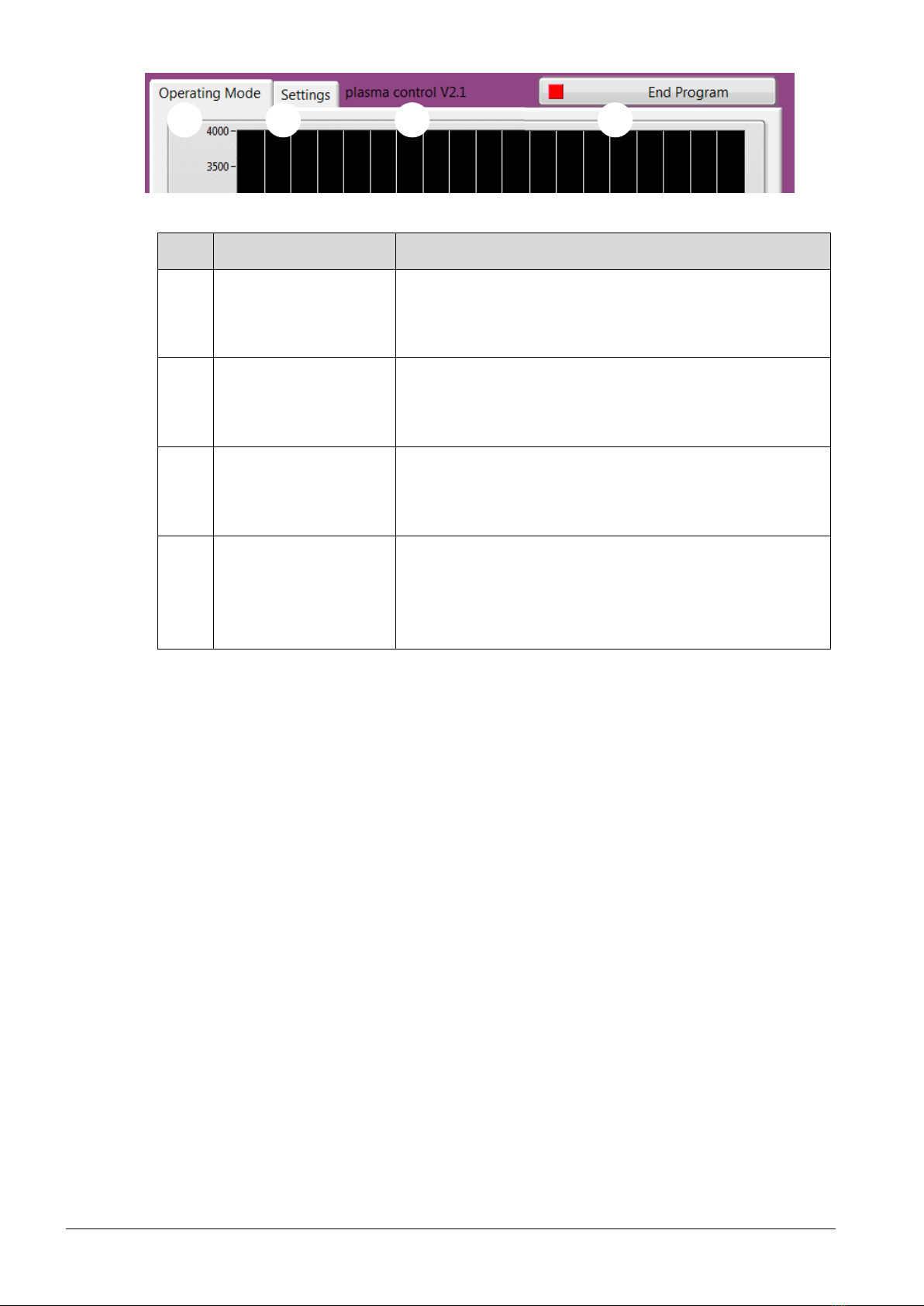

5.2 Operating the "plasma control" software...........................................................................................9

5.2.1 "Operating Mode" menu item............................................................................................11

5.2.2 "Settings" menu item ........................................................................................................13

5.2.3 Data recording sample file ................................................................................................14

6Environment............................................................................................................................15

6.1 Disposal ..........................................................................................................................................15