Inhaltsverzeichnis

BA-KommPN_EN / F0354700 Januar 2023 3

1 Safety ......................................................................................................................................... 4

1.1 Residual risks .................................................................................................................................... 4

1.2 Information and obligations for the operator ..................................................................................... 4

1.3 Intended use ..................................................................................................................................... 5

1.4 Impermissible operating conditions ................................................................................................... 5

2 System description ................................................................................................................... 6

2.1 Function ............................................................................................................................................ 6

2.2 System overview ............................................................................................................................... 6

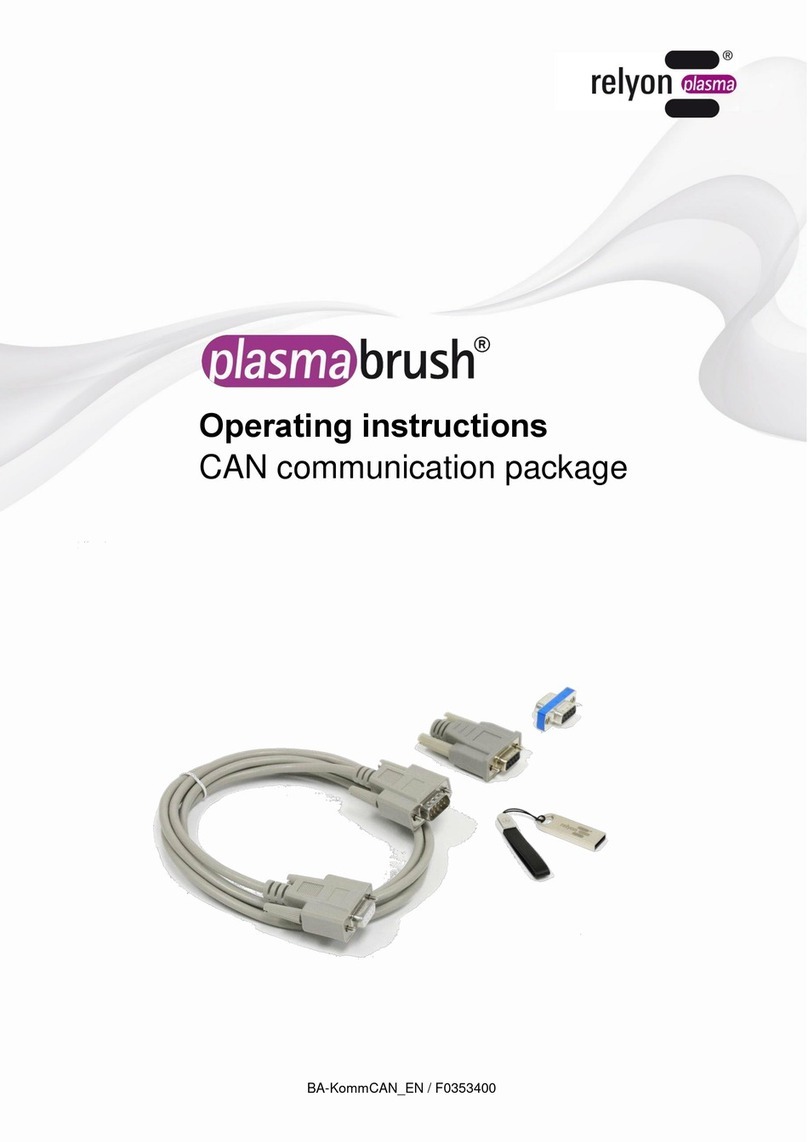

2.2.1 Description of the components ........................................................................................... 6

2.2.2 Scope of delivery ................................................................................................................ 7

2.2.3 Other hardware components needed ................................................................................. 7

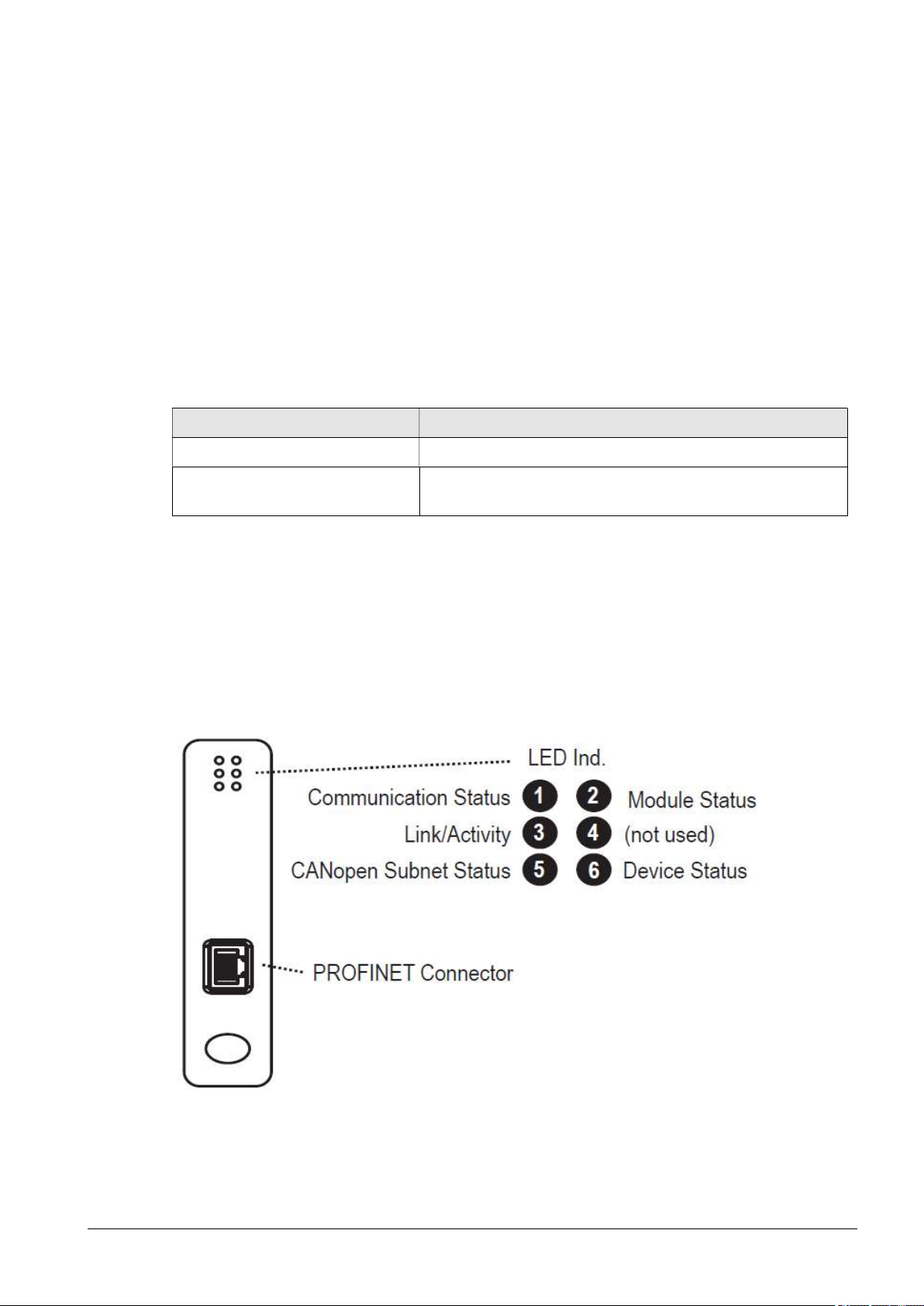

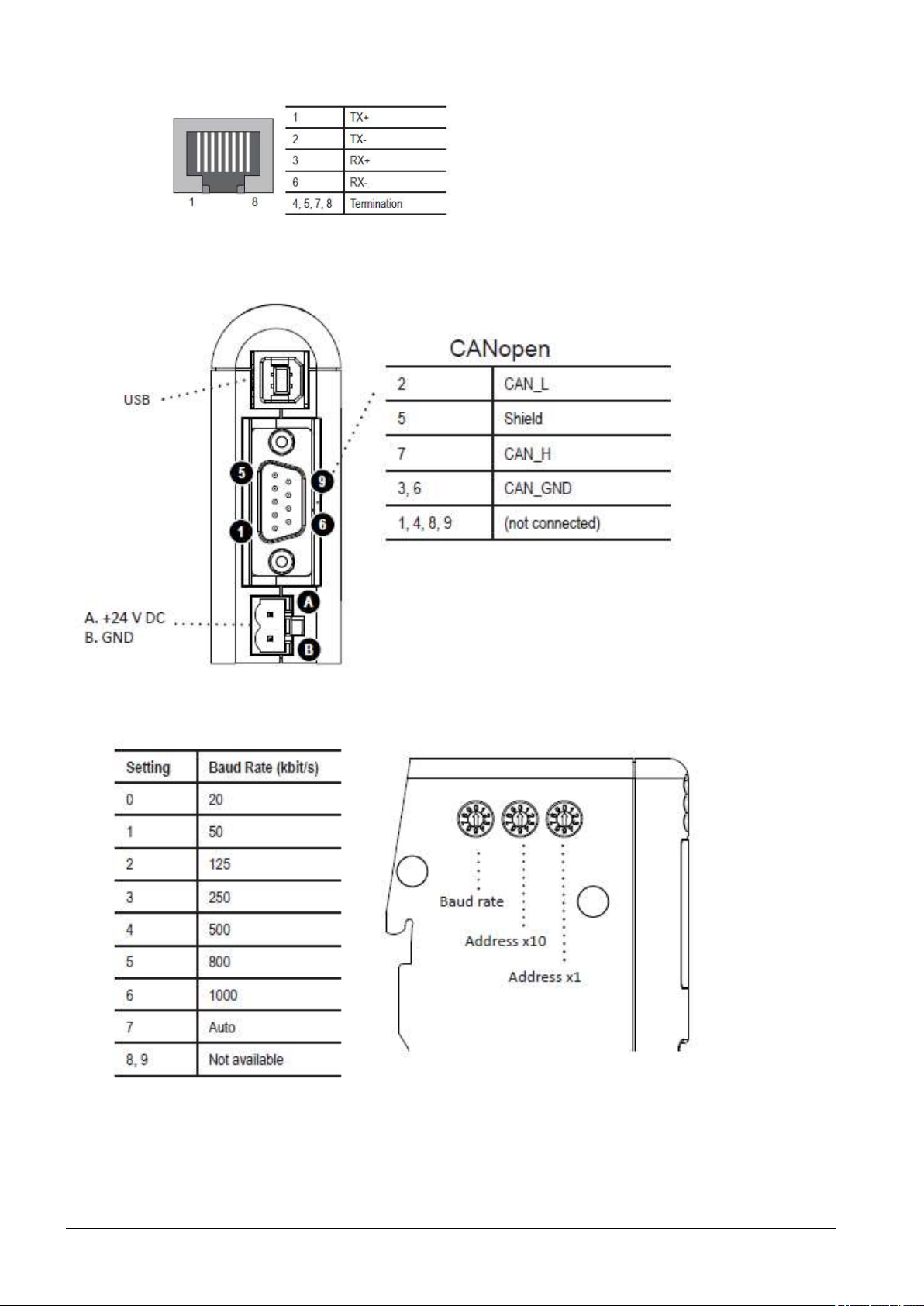

2.3 Connection assignments ................................................................................................................... 7

2.3.1 Anybus X-gateway control connection assignments .......................................................... 7

3 Technical data ........................................................................................................................... 9

4 Transport/Storage ..................................................................................................................... 9

5 Unpacking and Installation .................................................................................................... 10

5.1 Unpacking ....................................................................................................................................... 10

5.2 Installation requirements ................................................................................................................. 10

5.3 Installation ....................................................................................................................................... 10

6 Operation and configurations ................................................................................................ 12

6.1 Taking into operation ....................................................................................................................... 12

6.2 Anybus X-gateway CANopen Master Configuration ....................................................................... 12

6.3 PS2000 CANopen Slave Konfiguration .......................................................................................... 13

6.4 PDO mapping .................................................................................................................................. 13

6.5 Siemens configuration..................................................................................................................... 14

6.6 Error messages on the Anybus X-gateway..................................................................................... 16

7 Environment ............................................................................................................................ 17

7.1 Disposal .......................................................................................................................................... 17

8 Conformity / Standards .......................................................................................................... 17

8.1 CE ................................................................................................................................................... 17

8.2 Product standards ........................................................................................................................... 17