2

General Information

AeroMaster air handling units are manufactured in accordance with valid Czech and European regulations and technical standards.

AeroMaster air handling units must be installed and used only in accordance with this documentation.

e customer is responsible for any damages resulting from use other than intended.

e installation and operating documentation must be available for the operating and servicing sta.

It is advisable to store this documentation close to the installed air handling unit.

When handling, installing, wiring, commissioning, repairing or servicing the AeroMaster air handling units, it is necessary to observe valid safety rules, standards

and generally recognized technical rules. In particular, it is necessary to use personal protective work aids (e.g. gloves) because of sharp edges and corners when

performing any handling, installing, dismounting, repairing or checking of AeroMaster air handling units. All equipment connections must comply with the respective safety

standards and regulations.

Any changes or modications to individual components of the AeroMaster air handling units which could aect its safety and proper functioning are forbidden.

Before installing and using the AeroMaster air handling units, it is necessary to familiarize yourself with and observe the directions and recommendations included in the

following chapters.

e AeroMaster air handling units, including their individual parts, are not intended, due to their concept, for direct sale to end customers.

Each installation must be performed in accordance with a professional project created by a qualied air-handling designer who is responsible for the proper selection and

dimensioning of components concerning their suitability for a given application.

e installation and commissioning may be performed only by an authorized company licensed in accordance with generally valid regulations.

When disposing of components and materials, it is necessary to observe the respective environmental protection and waste disposal regulations. In case of nal unit

liquidation, it is necessary to follow the policy of dierential waste disposal. We recommend metal parts be scrapped and other parts be disposed of in accordance with

separated waste regulations.

Further information can be found in the AeroMaster Catalogue and in the AeroCAD designing software.

Up-to-date version of this document is available at website www.remak.eu

Application, Operating Conditions and Construction.....................................................................................................................................................................................................3

Manufacturer‘s Notification.............................................................................................................................................................................................................................3

Application and Operating Conditions...........................................................................................................................................................................................................3

Air-Handling Unit Construction.......................................................................................................................................................................................................................3

Air-Handling Unit Marking ................................................................................................................................................................................................................................3

Information and Safety Labels ........................................................................................................................................................................................................................3

Side Variability of Unit Connections ..............................................................................................................................................................................................................3

Goods Despatch....................................................................................................................................................................................................................................................................4

Delivery Content..................................................................................................................................................................................................................................................4

Transport and Storage.......................................................................................................................................................................................................................................4

Packaging..............................................................................................................................................................................................................................................................4

Transport and Handling of Air Handling Unit Components ......................................................................................................................................................................4

Rotary Heat Exchanger Transport..................................................................................................................................................................................................................6

Storage Conditions.............................................................................................................................................................................................................................................6

Installation .............................................................................................................................................................................................................................................................................6

Installation Site ...................................................................................................................................................................................................................................................6

Service Access.....................................................................................................................................................................................................................................................6

Pre-Installation Inspection...............................................................................................................................................................................................................................6

Identification of Air-Handling Unit Components .........................................................................................................................................................................................7

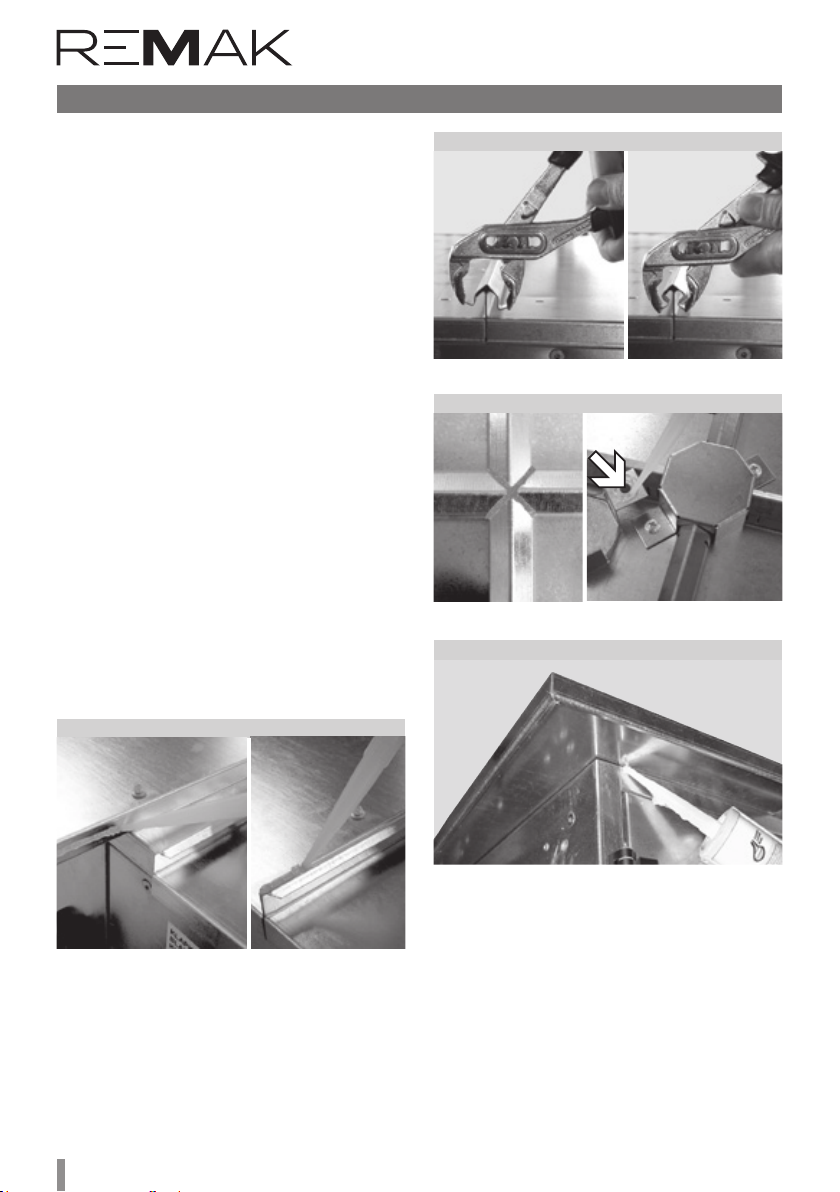

Assembly of Air-Handling Unit Sections.......................................................................................................................................................................................................7

Installation of Covering Roof............................................................................................................................................................................................................................8

Plate Heat Exchanger.........................................................................................................................................................................................................................................9

Rotary Heat Exchanger......................................................................................................................................................................................................................................9

Connection of Heat Exchangers ................................................................................................................................................................................................................................... 10

Water and Glycol Heat Exchangers............................................................................................................................................................................................................. 10

Connection of Water Heat Exchangers....................................................................................................................................................................................................................... 10

Direct Evaporators .......................................................................................................................................................................................................................................... 10

Steam humidification ...................................................................................................................................................................................................................................... 10

Condensate Drainage...................................................................................................................................................................................................................................... 11

Other Connections........................................................................................................................................................................................................................................................... 11

Air-handling Duct Connection....................................................................................................................................................................................................................... 11

Electric Equipment Wiring............................................................................................................................................................................................................................. 11

Wiring of Motors.............................................................................................................................................................................................................................................. 11

Wiring Diagrams – Fan Motors..................................................................................................................................................................................................................... 12

Wiring Diagrams – Electric Heaters............................................................................................................................................................................................................ 13

Start-Up Preparation and Commissioning .................................................................................................................................................................................................................... 16

Removing of Spacers from the Fan Section .............................................................................................................................................................................................. 16

Commissioning ................................................................................................................................................................................................................................................ 16

Inspection Prior the First Start-Up.............................................................................................................................................................................................................. 17

Operating Checks and Service Regulations .............................................................................................................................................................................................................. 17

Unit Operation - Service Regulations ......................................................................................................................................................................................................... 17

Unit Operation Screening Checks................................................................................................................................................................................................................ 17

Regular Inspections......................................................................................................................................................................................................................................... 17

Spare Parts and Service................................................................................................................................................................................................................................................... 24

Spare parts ......................................................................................................................................................................................................................................................... 24

Service................................................................................................................................................................................................................................................................. 24

Disposal............................................................................................................................................................................................................................................................... 24

Waste classification.......................................................................................................................................................................................................................................... 24

Complementary Information............................................................................................................................................................................................................................................ 25

XPRJ and XPRF Sections ................................................................................................................................................................................................................................ 25

Integrated Cooling Section.............................................................................................................................................................................................................................. 26

XPTG Section..................................................................................................................................................................................................................................................... 29

XPXB 28/BS Plate Heat Exchanger Section................................................................................................................................................................................................ 31

XPXR Regeneration Exchanger Section ....................................................................................................................................................................................................... 33

Stacks of AeroMaster XP Air Handling Unit Sections ................................................................................................................................................................................ 38

AeroMaster XP Air Handling Unit Adjustable and Fixed Feet.................................................................................................................................................................... 39

Removing the transport brace ..........................................................................................................................................................................................................................40

Air Flow Rate Determination for Fans with Overhung Impeller................................................................................................................................................................. 41

Connection of individual sections - complementary set XPSSSxxDR ..................................................................................................................................................... 41

Automatic Backup of Fan Motors ................................................................................................................................................................................................................... 42

Compact version of Air-Handling Units.......................................................................................................................................................................................................... 43

Air-handling units modified for clean plants and health service ................................................................................................................................................................ 47

Contents