3

Air Handling Units

Application, Operating Conditions and Construction

Manufacturer‘s Notication

AeroMaster air-handling units are manufactured in accor-

dance with valid Czech and European regulations and

technical standards. AeroMaster air-handling units must be

installed and used only in accordance with this documen-

tation. The installation and operating documentation must

be available for the operating and servicing staff, and it is

advisable to store this documentation close to the installed

air-handling unit.

Application and Operating Conditions

AeroMaster Cirrus air-handling units are designed for

comfortableair-handlingandair-conditioninginanairow

range corresponding to the air-handling unit’s cross-sec-

tionandrequiredairowvelocityfrom1.5-4m/satanair

pressure difference of the fan of up to 2500 Pa. The air-

-handling unit is designed as a modular system with a fra-

meandlaminatedconstructionwhichenableshighexibi-

lity.Thusindividualmodicationtocustomerrequirements

is possible. Inner width (W), height (H) and length (L) are

multiples of the module (N × 306 mm) and create space for

the installation of built-in functional assemblies.

AeroMaster Cirrus air-handling units are intended for

installationonoorsorsubstructures,andaredelivered

with a rigid base frame mounted in the factory.

Theyaredesignedtotransportairwithoutsolid,brous,

sticky, aggressive or explosive impurities. The transpor-

ted air must be free of corrosive chemicals or chemicals

aggressive to zinc and steel, respectively aluminium.

They are manufactured with the same construction for

inside as well as outdoor environments, including units

designed for rooms with greater requirements for cleanli-

ness. Air-handling units intended for outside environments

are completed with suitable accessories (roof, louvers,

etc.) ensuring correct and failure-free operation. With the-

se air-handling units, the correct selection, localization and

connection of the M&C components, including anti-freeze

protection, must be ensured.

AeroMaster Cirrus air-handling units can be used in

normalrooms(IEC60364-5-51,resp.ČSN332000-5-

51ed.2,ČSN332000-1ed.2)andinroomswithexten-

ded ambient temperature range from -30 °C to + 40 °C

without additional measures - applies to the standard

version. Custom-made units with decreased -40 °C to

+40 °C or increased -30 °C +50 °C temperature range

of transported air can be delivered.

When designing the air-handling assembly, it is

necessary to take into account the temperature and

humidity of the inlet and outlet air in relation to the

ambient temperature and humidity. It is especially

necessary to analyze the relation of the unit's casing

classicationpursuanttoEN1886andtheriskofcon-

densation, respectively ice build-up.

The device can be used for outdoor installations if

equipped with a protecting roof; the device is water

spray proof (rain up to 60° vertical slant) while obser-

ving the Installation and Operating Instructions.

The fans are equipped with motors insulated with F

class insulation of the winding.

The unit's noise level does not exceed max. allowed

valuesasperStatutoryOrderNo.176/2008Sb,Appen-

dix No. 1, Article 1.7.4.2., Letter u).

Air-Handling Unit Construction

The air-handling unit is designed as a modular system

with a frame and laminated construction. The walls consist

oftwolayersofuniedmodularlaminasattachedtothe

frame.Therstlayeroftheupper,lowerandbackwalls

has longitudinally-oriented laminas while the second la-

yerlaminasarecross-oriented.Thefrontwallttedwith

service panels has laminas oriented in the same direction

in both layers. The service parts (panels) are also of la-

minated construction. Each panel consists of the external

casing with integrated reinforcements.

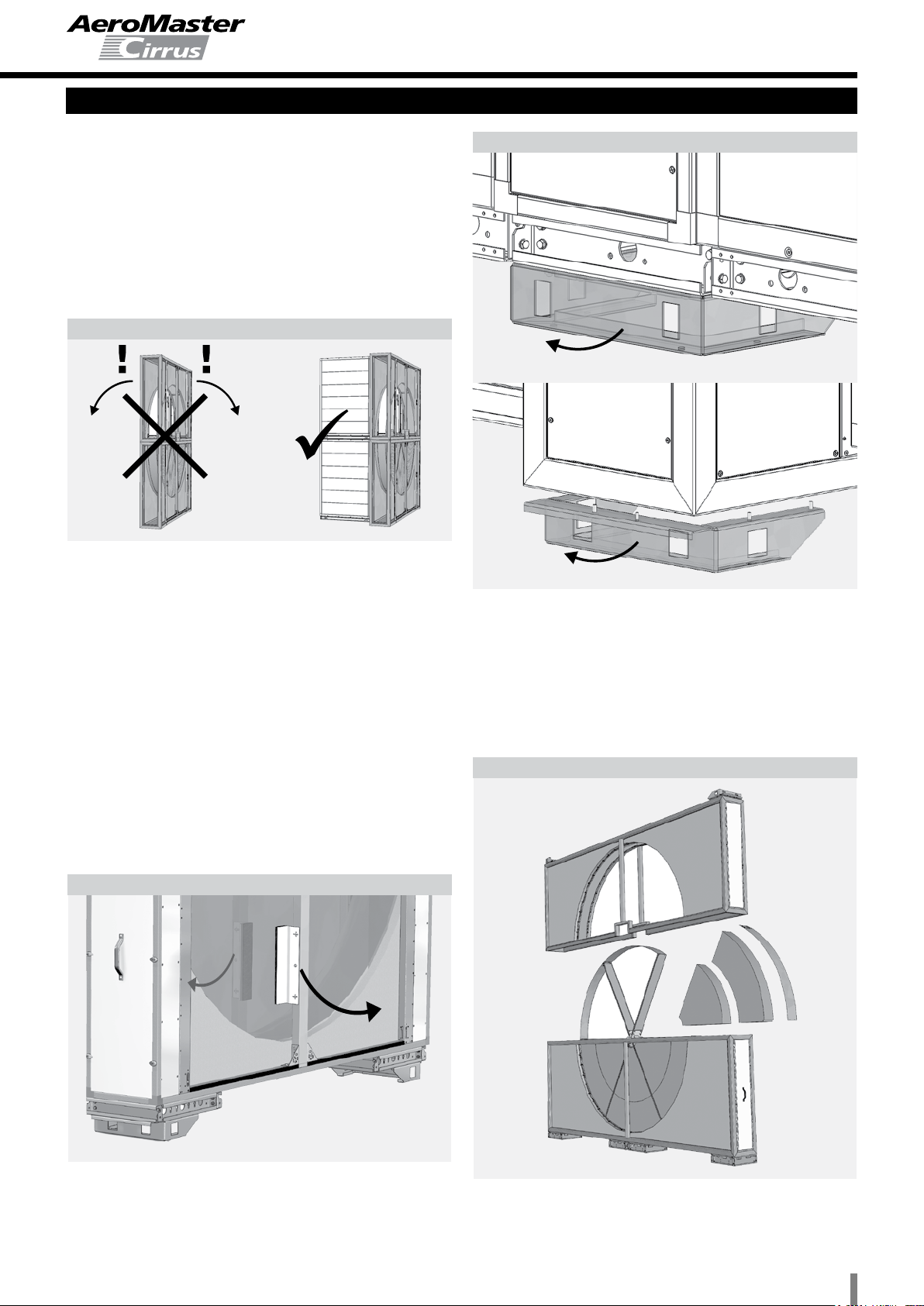

The panels which are expected to enable occasional servi-

ce access to the internal built-in assemblies are provided

with locks and grab handles to make handling easier. The

panelsusedforregularservicing(replacementoflter

inserts, cleaning of built-in assemblies, etc) are provided

with hinges and locks.

All walls are of sandwich construction with a total insu-

lation thickness of 50 mm. They are provided with a quality

anti-corrosionsurfacenish.Theconnectionsbetween

walls, panels and supporting cross-members are sealed

with a seal with closed cell structure.

The seals used during the assembly of the air-handling

unit’s lamellar walls and casing have a closed cell structu-

re. The non-glued replaceable sealing of the service pa-

nelsisttedintothegrooveontheinnersideofthepanel.

Internal casing: Standard version - galvanized sheet

steel, optionally painted sheet steel (polyester paint) or

stainless sheet steel

External casing: Standard version - galvanized sheet

steel, optionally painted sheet steel (polyester paint) or

stainless sheet steel

Frameproles:Standardversion-hot-dipgalvanized

sheet steel, optionally painted sheet steel (polyester paint)

Insulation of the upper and side panels is made of 50

mm thick non-combustible mineral wool (Class A1 pur-

suantČSNEN13501-1).

Insulation of the lower panels is made of 50 mm thick

PUR foam boards (Class B2 pursuant DIN 4102).

The joints are sealed with silicone compound.

Air-Handling Unit Marking

The complete AeroMaster Cirrus air-handling unit is

divided into "structural" BLOCKS, respectively transport-

installationBLOCKS.Functionally,theblockisdenedby

the internal built-in assembly (assemblies) which is (are)

ttedintotheblock'scasing,wherethecasingiscreated

with laminated walls, supporting cross-members and a

combination of service panels situated on the access side

of the unit.

The air-handling unit is then assembled from the trans-

port-installation blocks at the installation site. At the outlet,

thetransport-installationblocksarettedwithanendpanel

or a frame to be connected to the next block.

BLOCK is provided with a BLOCK type (name) plate

indicating the following data:

Manufacturer's name (incl. logo) and address

Type, size and marking code of the BLOCK

BLOCK serial number

Ordernumber(serialnumber)/yearofproduction

Weight